Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

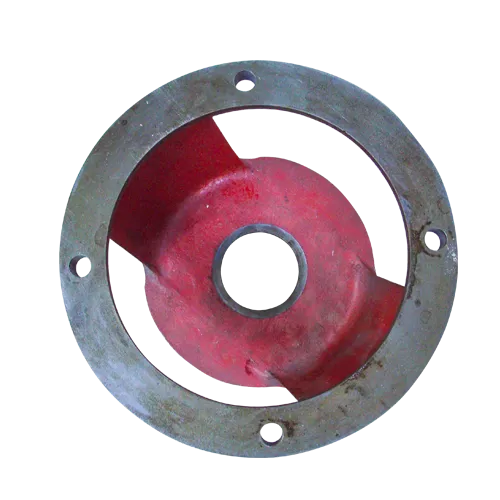

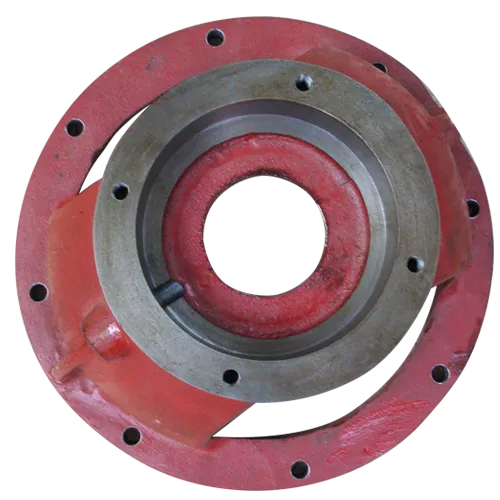

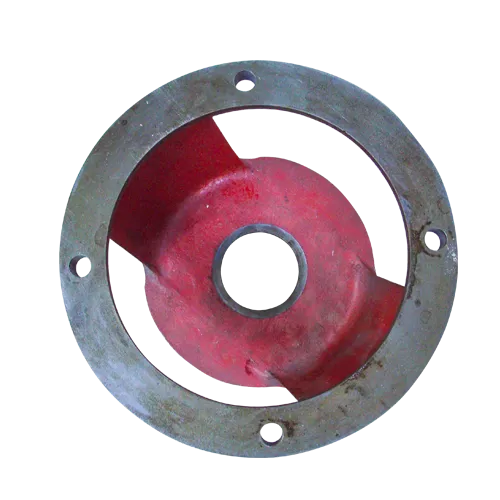

High-Performance Impeller for Pumps – Durable, Efficient, Reliable

As global demand for efficient fluid handling rises, impeller technology is rapidly evolving. Whether powering water treatment systems, petrochemical plants, or sophisticated metallurgy equipment, the impeller remains at the heart of every pump system. Today, we explore the latest industry trends, in-depth technical parameters, modern application scenarios, and advanced customization schemes—all centering upon the crucial role of the impeller and its structural partners, such as the Connector bracket.

The fluid machinery industry has witnessed exponential growth: reports predict the global impeller market to surpass $6.4 billion by 2028 (MRFR, 2023), fuelled by enhanced energy efficiency standards, material advancements, and stricter regulatory requirements. Modern impeller on pump applications prioritize:

- Optimized flow dynamics and hydraulic design to boost efficiency > 85%

- Corrosion-resistant materials such as duplex stainless steel and high-nickel alloys, ideal for water pump impeller or aggressive media

- Modular construction with cap ends and innovative pump casing integration

- Compliance with international standards (ISO 5199, ANSI B73.1, API 610)

- Smart monitoring for predictive maintenance

At the core of any pump system, the impeller dictates flow, pressure, and energy consumption. Below we present a comparative matrix of core technical specs for common impeller types, widely used in water, petrochemical, and process industries.

| Type | Material | Flow Rate Range (m³/h) |

Max Head (m) |

Efficiency (%) |

Corrosion Resistance | Compliance | Expected Lifespan (hrs) |

|---|---|---|---|---|---|---|---|

| Closed Impeller | CF8M SS / Duplex Steel | 8–500 | 150 | 85–92 | High (chlorides/chemicals) | ISO 5199, ANSI B73.1 | 30,000–40,000 |

| Semi-open Impeller | Bronze / Cast Iron | 15–400 | 90 | 76–84 | Medium (mild acids) | ISO 2858 | 20,000–30,000 |

| Open Impeller | 304/316 SS | 5–200 | 55 | 67–77 | Low-moderate | ANSI/ASME | 15,000–25,000 |

| Vortex Impeller | High Chrome Alloy | 12–180 | 38 | 72–82 | Very high (slurry/grit) | API 610 / ISO 13709 | 22,000–35,000 |

The following chart visualizes the rising technological specs for impellers over the past 5 years. Key metrics—efficiency, lifespan, and compliance—are steadily increasing, reflecting R&D investments and new composite materials.

Certified metals (SS, bronze, alloys) analyzed for composition, purity. Only ISO 9001-accredited sources used.

2. Casting or Forging

Sand or investment casting, followed by heat-treatment. For high-end, CNC-forged impellers minimize voids.

3. CNC Machining

5-axis CNC ensures precision of <0.01mm—critical for cap ends and pump casing fit.

4. Surface Treatment

Anti-corrosive coatings or polishing (Ra ≤ 3.2μm), extending lifespan and pump efficiency.

5. Inspection & Balancing (ISO 1940/1)

Dynamic balancing (G6.3 grade) & ultrasonic flaw detection guarantee vibration-free performance.

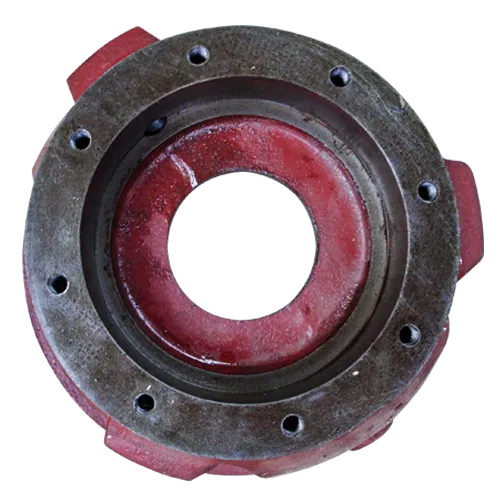

The Connector bracket provides a robust interface joining impeller assemblies to pump body structures or automation systems. Proper selection amplifies advantages across flow stability, alignment, service life, and ease of maintenance.

| Brand | Material Grade | Precision | Coating | Max Load (kg) | Certifications | Warranty (months) |

|---|---|---|---|---|---|---|

| YD Castings | CF8M / QT500-7 | ±0.005 mm | Epoxy + Nano-Silica | 410 | ISO 9001, ISO 14001, FDA | 36 |

| Cronin Pump Components | CZ132 / EN-GJS-400 | ±0.012 mm | PVC | 285 | ISO 9001 | 18 |

| GlobalFlowTech | SS316 / GGG40 | ±0.010 mm | Polyester | 320 | ISO 9001, ANSI | 24 |

| Parameter | Value | Method/Standard |

|---|---|---|

| Nominal Size (mm) | 65, 80, 100, 125, 150 | EN 1092-1 |

| Material | CF8M, QT500-7, SS316 | ASTM A351/A536 |

| Precision | ±0.005mm (CNC Machining) | VDI 3400 |

| Coating | Epoxy, Nano-Silica hybrid | ISO 12944 |

| Load Bearing (kg) | 410 | ISO 1461 |

| Corrosion Resistance | 24-hr salt spray (no rust) | ASTM B117 |

| Certification | ISO 9001, ISO 14001, FDA | --- |

With more than 25 years of industrial experience, YD Castings delivers full-spectrum custom impeller solutions—from initial CFD design and rapid prototyping, to scalable mass production and international logistics. Recent bespoke applications include:

Case B: Metallurgical Slurry Transfer — Engineered a self-cleaning vortex impeller and heavy-duty cap ends, certified to ISO 13709, withstood 9,300 hr in abrasive slurry service—twice the industry average.

Case C: Wastewater Aeration — Deployed ultra-light composite impeller on pump, realized energy savings of 21% at Shanghai WWTP, with full remote asset monitoring per EPA standards.

- Petrochemical process pumps (corrosive/abrasive fluids)

- Municipal & industrial wastewater (high solids content)

- Desalination & clean water supply (low fouling, FDA compliance)

- Thermal power cooling circuits (high flow, high temperature)

- Steel & metallurgy (slurry/scrap transport, heavy-duty service)

- Food & beverage processing (sanitary-grade alloys, hygienic designs)

- Mining sector (grit/slurry, severe impact environment)

- Testing: 100% dynamic balancing (ISO 1940/1), PMA X-ray checks, and hydrostatic pressure testing up to 30 bar.

- Lead Time: Standard parts: 20 days; Custom impeller/connector bracket: 30-45 days.

- Warranty: 36 months for manufacturing defects.

- Support: 24/7 remote engineer access, direct spare parts logistics, and on-site commissioning by certified technicians.

- Industry Certification: Every part batch is supplied with ISO/EN test reports, chemical analysis, and third-party inspection option (SGS, TÜV).

- GlobalPetroChem GmbH: “The robust connector bracket and precision impeller reduced downtime by 43% over 18 months.”

- Shanghai Wastewater Treatment Consortium: “YD Castings’ impeller helped us meet strict effluent targets—energy usage dropped significantly.”

- European Valve Manufacturer: “Excellent corrosion resistance—no failures observed even after 2 years in acidic brine.”

-

ISO/ANSI/API Compliant: All processes fully certified for design & manufacturing.

-

TÜV Rheinland: Regular process audits and independent product validation.

TÜV Rheinland: Regular process audits and independent product validation.

-

SGS, WRAS, FDA certifications available for key export markets.

SGS, WRAS, FDA certifications available for key export markets.

- 🛒 Visit product page: Connector bracket details & inquiry form.

- 📧 Contact technical sales: sales@ydcastings.com – rapid response guaranteed within 12 hours.

- 📞 Phone/WhatsApp: +86 137 3618 9784

- 📁 Download: Drawings/spec sheets/3rd party test reports (on request)