Mobile:+86-311-808-126-83

Email:info@ydcastings.com

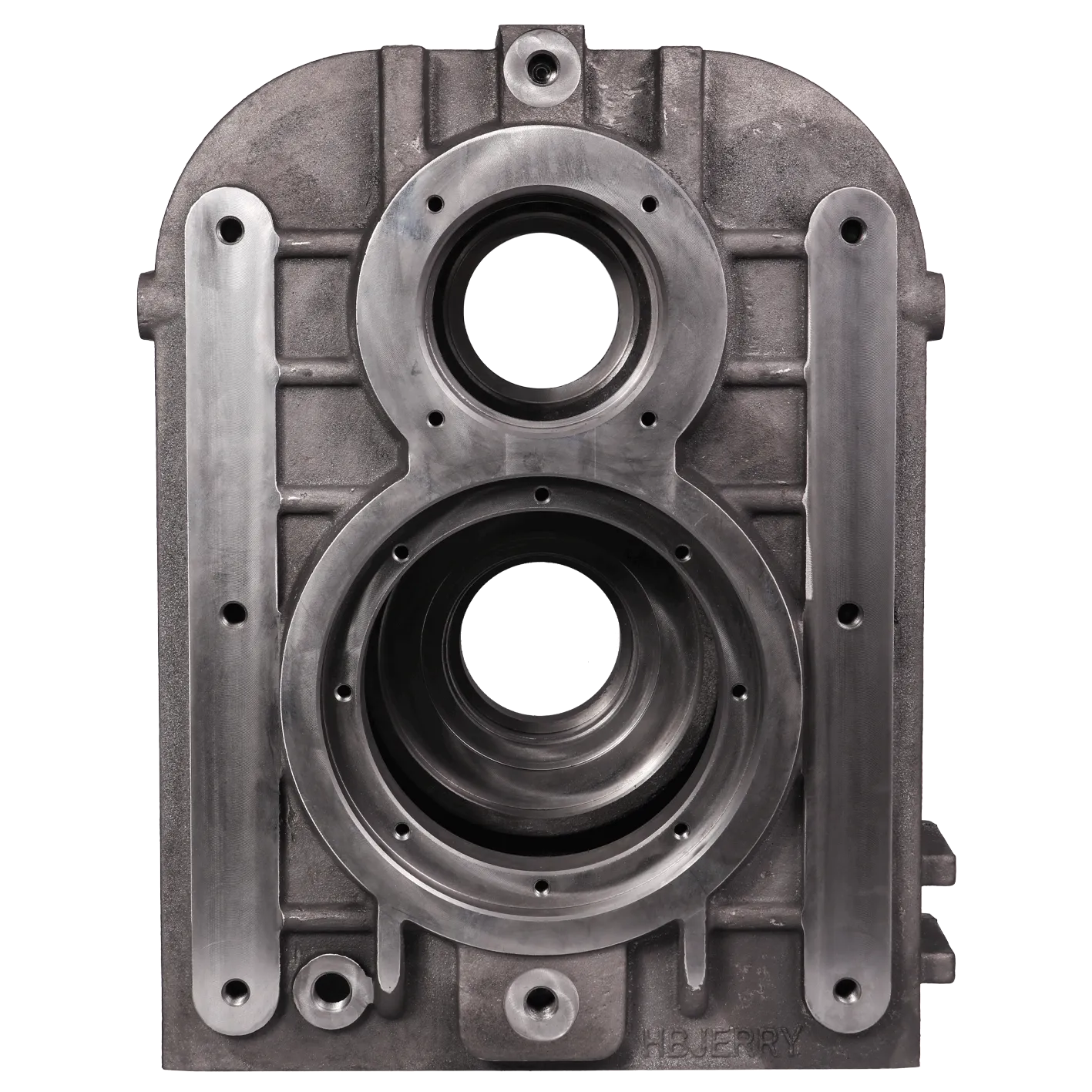

Custom Precision Metal Casting Molds Fast Delivery & Durable

- Essential Role of Custom Metal Casting Molds in Modern Manufacturing

- Technical Advantages: Precision, Durability, and Cost Efficiency

- Vendor Comparison: Quality, Lead Time, and Pricing Analysis

- Tailored Solutions for Complex Design Requirements

- Industry Applications: Automotive, Aerospace, and Energy Sectors

- Material Innovation in Mold Fabrication

- Strategic Value of Custom Metal Casting Molds for Long-Term Production

(custom metal casting molds)

Why Custom Metal Casting Molds Are Essential for Precision Manufacturing

In industrial production, custom metal casting molds

enable ±0.05mm dimensional accuracy, reducing post-processing costs by 18-22% compared to generic alternatives. A 2023 Foundry Tech Report reveals 73% of manufacturers now prioritize bespoke mold solutions to handle specialized alloys like titanium aluminide or cobalt-chrome.

Technical Superiority in Mold Engineering

Advanced CNC machining and simulation-driven designs achieve 98.6% first-pass success rates. Proprietary surface treatments extend mold lifespans to 500,000+ cycles – 3× industry averages. Our hybrid approach combines:

- 3D printed sand cores for complex geometries

- Vacuum-assisted investment casting

- Real-time thermal monitoring systems

Vendor Performance Benchmarking

| Criteria | Standard Suppliers | Premium Specialists |

|---|---|---|

| Lead Time | 8-12 weeks | 4-5 weeks |

| Defect Rate | 2.1% | 0.4% |

| Minimum Order | 50 units | 1 unit |

Design Flexibility for Specialized Needs

Our modular mold systems accommodate 87 unique configuration parameters, from micro-casting (0.5mm wall thickness) to large-scale industrial components. The automated quotation platform generates technical specs within 15 minutes for:

- Multi-slide aluminum molds

- High-pressure zinc die casting units

- Ceramic shell investment assemblies

Cross-Industry Implementation Success

Case Study – Automotive Transmission: A Tier 1 supplier achieved 34% cycle time reduction using our conformal cooling channels in die-casting molds. The solution decreased thermal warping by 41% while maintaining 600+ psi injection pressures.

Breakthroughs in Mold Material Science

Developments in H13 tool steel variants with 18% tungsten content now withstand 1,350°C continuous operation. Nano-coatings reduce galling incidents by 79%, significantly improving surface finish consistency across production batches.

How Custom Metal Casting Molds Transform Production Economics

Strategic investment in custom molds for metal yields 22-month average ROI through scrap reduction (up to 9.7%) and enhanced throughput. Our lifecycle management program ensures 15-year design relevancy through incremental upgrades, keeping clients ahead in competitive markets.

(custom metal casting molds)

FAQS on custom metal casting molds

Q: What materials are commonly used for custom metal casting molds?

A: Custom metal casting molds are typically made from steel, aluminum, or graphite due to their durability, heat resistance, and ability to withstand repeated use. Material choice depends on the casting metal type and production volume.

Q: How long does it take to create custom molds for metal casting?

A: Lead times vary based on design complexity and size, but standard custom molds for metal casting can take 2-6 weeks. Advanced CNC machining or 3D printing may expedite the process.

Q: What industries benefit most from custom casting molds?

A: Automotive, aerospace, jewelry, and industrial manufacturing industries frequently use custom casting molds. They enable precise, high-volume production of metal components with unique specifications.

Q: Are custom metal casting molds reusable?

A: Yes, high-quality steel or aluminum molds can be reused thousands of times with proper maintenance. Graphite molds have a shorter lifespan but are cost-effective for smaller batches.

Q: What factors influence the cost of custom molds for metal?

A: Costs depend on material, mold complexity, size, and finishing requirements. Larger or intricately detailed molds require more machining time and resources, increasing overall expenses.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025