Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Feb . 18, 2025 06:23

Back to list

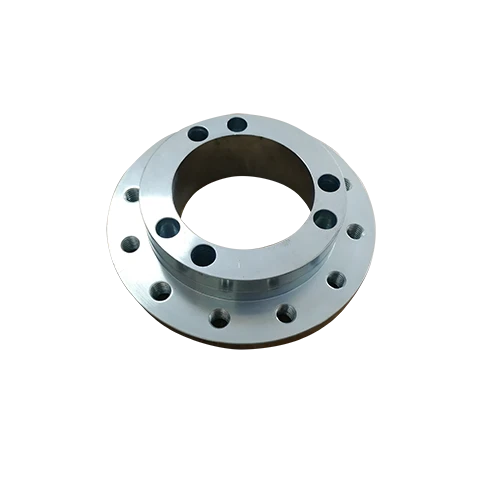

1 pipe end cap

A well-chosen pipe end cap plays a critical role in the plumbing, construction, and municipal industries, enhancing systems' integrity by securely sealing pipe ends. Exploring the key considerations for selecting and utilizing pipe end caps can significantly amplify their long-term efficacy and optimize lifecycle costs.

Installation procedures further denote the effectiveness of pipe end caps. Incorrect installation might lead to system leaks or loss of pressure integrity. It is imperative to adhere to manufacturer recommendations and employ experienced technicians for installation, especially in critical systems like gas pipelines or municipal water supplies. This ensures that the cap remains secure under operational stresses. The regulatory standards for pipe end caps also speak to their reliability and safety. Aligning with industry standards such as ASTM or ASME ensures that the end cap is manufactured to withstand prescribed environmental and operational challenges. Such adherence contributes to advancing trustworthiness, especially when used in vital infrastructure projects. Moreover, routine inspection and maintenance are vital in safeguarding the cap's long-term functionality. Experienced engineers underscore regular checks for wear and tear, especially in systems experiencing significant temperature or pressure fluctuations. Proactive maintenance strategies not only enhance system reliability but also prevent costly downtime. Additionally, sustainability impacts are gaining importance. Manufacturers increasingly seek eco-friendly materials and production processes for pipe end caps in response to environmental concerns. Utilizing recyclable materials contributes to sustainable development goals and reduces the carbon footprint associated with infrastructure projects. In conclusion, the discerning selection and use of pipe end caps underscore the importance of expertise and a detailed understanding of application contexts. Combining practical experience with industry standards results in the optimal selection and use of these essential components, underpinning the effectiveness and safety of varied systems across industries. Such a strategy enhances not only the efficiency and reliability of the infrastructure but also upholds the environmental accountability increasingly demanded in today's market.

Installation procedures further denote the effectiveness of pipe end caps. Incorrect installation might lead to system leaks or loss of pressure integrity. It is imperative to adhere to manufacturer recommendations and employ experienced technicians for installation, especially in critical systems like gas pipelines or municipal water supplies. This ensures that the cap remains secure under operational stresses. The regulatory standards for pipe end caps also speak to their reliability and safety. Aligning with industry standards such as ASTM or ASME ensures that the end cap is manufactured to withstand prescribed environmental and operational challenges. Such adherence contributes to advancing trustworthiness, especially when used in vital infrastructure projects. Moreover, routine inspection and maintenance are vital in safeguarding the cap's long-term functionality. Experienced engineers underscore regular checks for wear and tear, especially in systems experiencing significant temperature or pressure fluctuations. Proactive maintenance strategies not only enhance system reliability but also prevent costly downtime. Additionally, sustainability impacts are gaining importance. Manufacturers increasingly seek eco-friendly materials and production processes for pipe end caps in response to environmental concerns. Utilizing recyclable materials contributes to sustainable development goals and reduces the carbon footprint associated with infrastructure projects. In conclusion, the discerning selection and use of pipe end caps underscore the importance of expertise and a detailed understanding of application contexts. Combining practical experience with industry standards results in the optimal selection and use of these essential components, underpinning the effectiveness and safety of varied systems across industries. Such a strategy enhances not only the efficiency and reliability of the infrastructure but also upholds the environmental accountability increasingly demanded in today's market.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS