Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

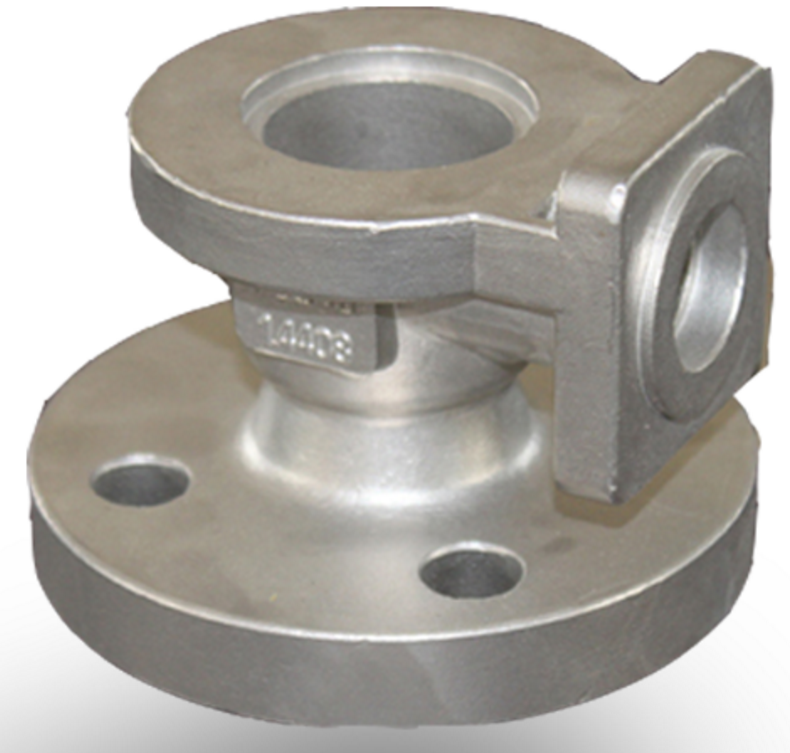

Valve Body & Castings – Precision, Durable, OEM Solutions

Ventilkörper is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of castings. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Valve Body Overview

- Benefits & Use Cases of Valve Body in Manufacturing of castings

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Valve Body from Welcome To Hebei Yuanda Trade Co., Ltd.

Valve Body Overview

A valve body is the pressure-retaining casting at the heart of industrial valves, engineered to route, start, and stop the flow of liquids or gases in pipelines. In Fabricated metal products and the Manufacturing of castings, the valve body is where material science, casting precision, and machining accuracy converge. Typical valve body castings are produced in ductile iron, gray iron, carbon steel, or stainless steel and then CNC-machined to tight tolerances to ensure leak-tight sealing and reliable actuation. Depending on the specification, designs can meet common pressure classes (e.g., PN10–PN25 or ANSI Class 150–600), corrosion-resistance requirements, and media compatibility for waterworks, oil and gas, HVAC, and general industrial use.

- Relevance: The valve body ensures structural integrity and flow path geometry, directly impacting service life, safety, and lifecycle cost of the full valve assembly.

- Technical background: Sand and resin-bonded sand casting are common, followed by heat treatment and precision machining of sealing faces, threads, and bores. Non-destructive tests (visual, dimensional, pressure tests) validate performance.

- Manufacturer reliability: Welcome To Hebei Yuanda Trade Co., Ltd. provides engineered valve body castings tailored to drawings, materials, and surface requirements, supporting consistent quality for global B2B buyers.

Benefits & Use Cases of Ventilkörper in Manufacturing of castings

Valve body castings underpin critical infrastructure—municipal water networks, wastewater plants, chemical processing, energy, and HVAC. In waterworks, for example, durable iron bodies pair with components such as cast iron water valve cover and water valve cover cast iron assemblies in underground boxes to protect operating gear. For industrial lines, robust geometries handle pressure cycles, thermal variation, and corrosive media. By optimizing gating and riser designs, foundries achieve sound castings with minimal porosity, enabling consistent sealing in the finished valves.

- Applications: Gate, globe, check, ball, and butterfly valve bodies for water, steam, chemicals, and slurries; municipal use alongside cast iron valve box cover systems; OEM replacements and new equipment builds.

- Advantages: Material flexibility (ductile iron to stainless steel), strong wall-thickness control, accurate machining of seats and ports, and coatings for corrosion resistance—all contributing to long service life and lower maintenance.

- Expertise: Welcome To Hebei Yuanda Trade Co., Ltd. supports end-to-end—from drawing review and mold development to casting, machining, and inspection—delivering dependable valve body performance for B2B buyers.

Cost, Maintenance & User Experience

Total cost of ownership for a valve body centers on casting quality, machining accuracy, and appropriate material selection. Upfront savings disappear if porosity, warpage, or misalignment cause leaks or premature wear. A well-engineered valve body minimizes seal failure, reduces unplanned downtime, and simplifies lifecycle maintenance—key drivers of ROI for utilities and industrial plants. Specifying valve body castings with proper coatings and corrosion protection further extends service intervals, especially in buried water applications where compatible components like a cast iron valve box cover protect operating mechanisms and accesses.

- TCO & durability: Material-grade optimization and precise machining lower leakage risk, spare-part consumption, and labor costs over years of service.

- User experience: B2B customers in Fabricated metal products value consistent dimensions, clean cast surfaces, and on-time delivery—areas where Welcome To Hebei Yuanda Trade Co., Ltd. focuses to support easier assembly and reliable field performance.

Sustainability & Market Trends in manufacturing

Casting manufacturers are advancing sustainability through higher scrap-recycling rates, sand reclamation, and energy-efficient melting. Regulatory and customer pressures for traceability and reduced carbon intensity are shaping how valve body supply chains are sourced and audited. In parallel, utilities and process industries are modernizing networks, driving demand for dependable valve body castings and related components such as water valve cover cast iron and cast iron valve box cover solutions for underground installations.

- Trend impact: Lower-emission materials and digital process control help improve casting yield and reduce waste without compromising mechanical properties or dimensional stability.

- Forward-thinking partner: Welcome To Hebei Yuanda Trade Co., Ltd. aligns with eco-conscious practices and continuous improvement, helping buyers meet quality, compliance, and sustainability targets in one integrated sourcing strategy.

Conclusion on Valve Body from Welcome To Hebei Yuanda Trade Co., Ltd.

For B2B decision makers, the valve body is a mission-critical casting that determines reliability, safety, and lifecycle cost across waterworks and industrial applications. With material versatility, precise machining, and rigorous inspection, Welcome To Hebei Yuanda Trade Co., Ltd. delivers valve body castings that help reduce maintenance and improve ROI. From municipal infrastructure to process plants, partner with a manufacturer equipped to meet your drawings, timelines, and quality goals.

- Value recap: Durable, accurate, and application-ready valve body solutions for Fabricated metal products and Manufacturing of castings.

- Reputation: A trusted partner focused on engineering support, consistent quality, and dependable delivery.

- Strong CTA: Contact us: email: info@ydcastings.com — Visit our website: https://www.ydcastings.com — Product detail: Ventilkörper

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025