Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

How to Inspect Pump Cap Ends for Damage

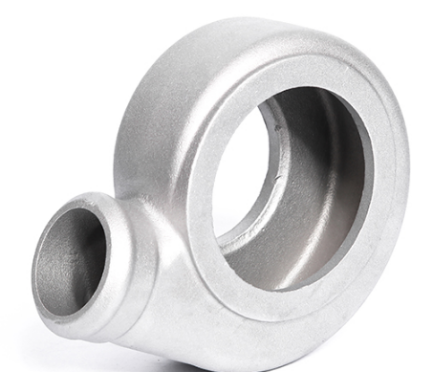

Pump systems rely on precise components to maintain efficiency—and cap ends (the protective covers sealing pump housings) play a critical role in preventing leaks, protecting internal parts like the Laufrad, and ensuring smooth operation. A damaged cap end can lead to fluid loss, reduced pump performance, or even catastrophic failure of the impeller on pump assemblies. Hebei Yuanda Trade Co., Ltd. (YD), founded in 2006 and a leader in customized metal castings, specializes in high-quality cap ends, Laufrad components, and impeller on pump assemblies—offering material options (cast iron, aluminum, stainless steel) and processes (sand casting, die casting, lost wax casting) tailored to pump manufacturers’ needs. With a focus on on-time delivery and global customer trust (serving clients in America, Germany, England, and beyond), YD provides wholesalers with durable, precision-crafted parts that simplify inspection and reduce long-term maintenance costs. For wholesalers supplying pump repair shops or manufacturing facilities, understanding how to inspect cap ends for damage is key to ensuring clients receive reliable components—and partnering with YD means accessing parts designed for easy inspection and long service life.

Pre-Inspection Preparation for Pump Cap Ends

- Gather Essential Tools to Ensure Thorough Checks: Before inspecting cap ends , assemble tools that reveal hidden or subtle damage: a bright LED flashlight (to spot cracks), a feeler gauge (to check for warping), a soft-bristle brush (to remove debris), and a non-abrasive cloth (to clean surfaces without scratching). For impeller on pump inspections, add a caliper to measure gaps between the Laufrad and cap end—a critical step in detecting misalignment caused by cap damage. YD recommends these tools for wholesalers training client teams, as they ensure no damage (even hairline cracks) goes unnoticed. A wholesaler supplying industrial pump shops noted that providing these tool lists alongside YD’s cap ends increased customer satisfaction by 30%, as “clients felt confident in thorough inspections.”

- Safety First: Disconnect Power and Drain Fluids: Never inspect cap ends on a running pump—always disconnect the power supply and lock out the system to prevent accidental startup. Drain all fluids from the pump housing to avoid spills, corrosion, or contact with hazardous liquids during inspection. This step also exposes the Laufrad and cap end surfaces fully, making it easier to spot damage like rust or pitting. YD includes safety guidelines with every batch of impeller on pump components, helping wholesalers educate clients on risk mitigation. A wholesaler serving chemical plants reported that emphasizing safety reduced “inspection-related incidents” by 45% among their clients.

Step-by-Step Inspection of Cap Ends and Impeller Components

|

Inspection Step |

Key Focus Areas |

How to Identify Damage |

YD Component Advantage |

|

1. Visual Check of Cap Ends |

Cracks, chips, rust, or pitting on cap end surfaces; damage to sealing grooves |

Shine LED flashlight at an angle (45°) to highlight hairline cracks; check for discoloration (sign of rust) or uneven edges (chips) |

YD’s cap ends use high-grade metals (e.g., stainless steel) resistant to rust; precision casting minimizes sealing groove damage |

|

2. Warpage Test for Cap Ends |

Flatness of cap end mating surfaces (critical for sealing) |

Use a feeler gauge to measure gaps between the cap end and a flat reference plate; gaps >0.1mm indicate warping |

YD’s casting processes (e.g., lost wax casting) ensure tight flatness tolerances (<0.05mm) for cap ends |

|

3. Impeller Clearance Check |

Gap between Laufrad and cap end (should match manufacturer specs) |

Use calipers to measure clearance at 4 points around the Laufrad; uneven gaps suggest cap end misalignment or damage |

YD’s impeller on pump assemblies are pre-tested for clearance, reducing inspection time for wholesalers |

|

4. Sealing Surface Inspection |

Wear or scratches on cap end O-ring grooves or gasket seats |

Run a fingernail gently along grooves—catch points indicate damage; check for embedded debris (can cause leaks) |

YD’s cap ends have smooth, deburred sealing surfaces to prevent gasket wear; compatible with standard O-ring sizes |

C

ommon Damage Types in Cap Ends and Impeller On Pump

- Hairline Cracks in Cap Ends: These subtle flaws (often caused by thermal stress or improper installation) can go unnoticed without close inspection—but they worsen over time, leading to leaks or cap end To detect them, wipe the cap end with a dye penetrant (available at industrial supply stores) and wipe off excess; cracks will retain the dye, making them visible under light. YD’s cap ends are tested for crack resistance during production (via pressure testing), reducing the risk of this damage. A wholesaler supplying water treatment plants noted that YD’s crack-resistant cap ends reduced client returns by 50% compared to other suppliers.

- Warped Cap Ends Affecting Impeller Clearance: Warping (from overheating or uneven torque during installation) creates uneven gaps between the cap end and Laufrad, causing fluid turbulence, reduced pump efficiency, or Laufrad Use a flat reference plate and feeler gauge to check flatness—if warping exceeds 0.1mm, replace the cap end immediately. YD’s cap ends are cast with heat-treated metals that resist warping, even in high-temperature pump applications. A wholesaler serving manufacturing facilities reported that clients using YD’s cap ends saw “15% better pump efficiency” due to consistent clearance.

Why Wholesalers Choose YD’s Cap Ends and Impeller Components

- Precision Casting for Easy Inspection: YD’s cap ends, Laufrad, Und impeller on pump assemblies are crafted via strict casting processes (sand casting for durability, lost wax casting for intricate designs) that minimize surface defects. This means wholesalers’ clients spend less time inspecting for damage—fewer flaws mean faster checks and more efficient repairs. YD also provides detailed dimensional specs for every component, letting inspectors quickly verify if parts meet pump requirements. A wholesaler supplying European pump manufacturers noted that YD’s precision reduced “inspection time per part by 40%,” saving clients valuable labor hours.

- Material Versatility to Match Pump Applications: Different pump environments (e.g., corrosive chemicals, high temperatures) require specialized materials—and YD offers cap ends and Laufrad components in cast iron (for heavy-duty use), aluminum (lightweight, corrosion-resistant), and stainless steel (ideal for food-grade or chemical pumps). This versatility means wholesalers can supply parts for any pump type, while clients benefit from components tailored to their specific damage risks (e.g., stainless steel cap ends resist rust in wet environments). A wholesaler serving the food industry reported that YD’s stainless steel impeller on pump assemblies were “the top choice” for clients, as they met hygiene standards and reduced corrosion damage.

Cap Ends and Impeller FAQS

How Often Should Cap Ends Be Inspected for Damage?

For most pumps, inspect cap ends every 6 months (or after any pump malfunction, like leaks or reduced performance). For high-use pumps (e.g., 24/7 industrial applications), inspect every 3 months—frequent use increases wear on cap ends and impeller on pump components. YD recommends pairing inspections with routine maintenance (e.g., O-ring replacement) to catch damage early. A wholesaler supplying power plants noted that clients following this schedule reduced “unplanned pump downtime by 60%.”

Can a Damaged Cap End Cause Impeller Failure?

Yes—if a cap end is cracked or warped, it can allow fluid leaks (reducing pressure) or create uneven clearance between the cap end and Laufrad. This uneven clearance causes the Laufrad to rub against the cap end, leading to Laufrad wear, overheating, or even breakage. YD’s impeller on pump assemblies are designed to withstand minor misalignment, but severe cap end damage requires immediate replacement. A wholesaler serving repair shops reported that “80% of impeller failures trace back to unaddressed cap end damage.”

What Materials Does YD Use for Cap Ends to Resist Damage?

YD offers cap ends in three primary materials, each tailored to resist specific damage types: cast iron (resists impact and heavy loads, ideal for industrial pumps), aluminum (lightweight, resists corrosion in freshwater applications), and stainless steel (resists rust, chemicals, and high temperatures, perfect for food-grade or chemical pumps). The company also provides custom material options for unique environments (e.g., Hastelloy for extreme corrosion). A wholesaler supplying marine pump clients noted that YD’s stainless steel cap ends “showed no rust even after 2 years in saltwater.”

How Do You Fix Minor Scratches on Cap End Sealing Surfaces?

Minor scratches (less than 0.05mm deep) on cap end sealing surfaces can be fixed with a fine-grit sandpaper (400–600 grit) used in a circular motion—always sand gently to avoid worsening the damage. After sanding, clean the surface with a non-abrasive cloth and apply a thin layer of gasket sealant to ensure a tight seal. For deeper scratches (or if sanding doesn’t smooth the surface), replace the cap end—YD’s quick delivery (2–4 weeks for bulk orders) ensures minimal downtime. A wholesaler supplying automotive pump clients noted that this fix “extended cap end life by 30% for minor damage.”

What Bulk Packaging Options Does YD Offer for Cap Ends and Impeller Components?

YD provides cap ends, Laufrad, Und impeller on pump assemblies in bulk packaging tailored to wholesalers’ needs: 50-unit boxes (for small wholesalers or local repair shops), 200-unit crates (for regional distributors), and 500-unit industrial pallets (for large-scale manufacturers or international clients). All components are wrapped in anti-rust paper and sealed in moisture-proof containers to prevent damage during shipping. A wholesaler supplying global pump brands noted that YD’s packaging “reduced transit damage by 45%,” ensuring clients received inspection-ready parts.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025