Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

Stainless Steel Casting Experts - Precision, Durable, Custom

Stainless Steel Casting is a key solution in the manufacturing industry, specifically within foundries and Manufacturing of metal castings. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Steel Casting Overview

- Benefits & Use Cases of Stainless Steel Casting in Manufacturing of metal castings

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Stainless Steel Casting from Welcome To Hebei Yuanda Trade Co., Ltd.

Stainless Steel Casting Overview

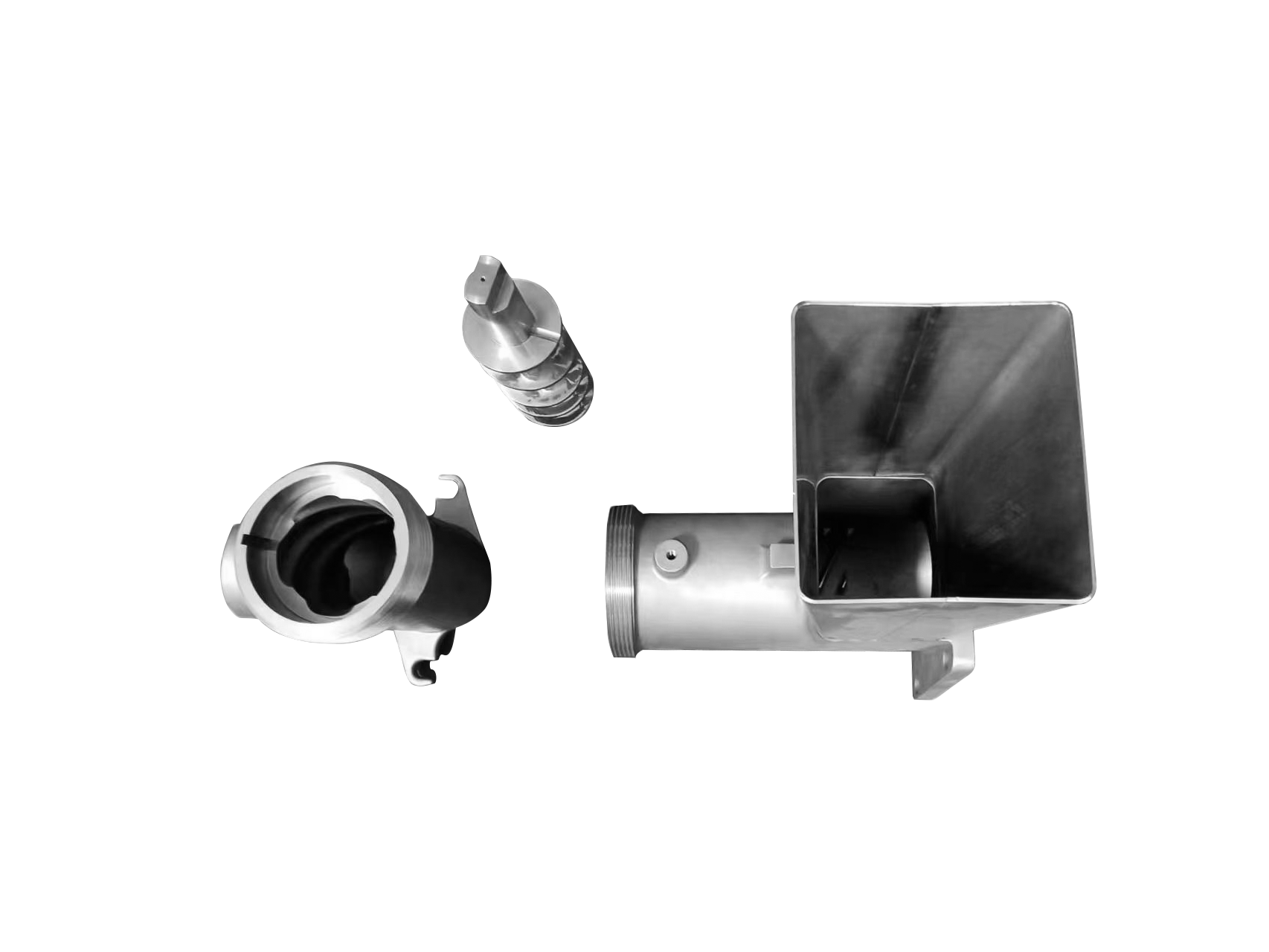

Stainless Steel Casting is the process of shaping corrosion-resistant iron-based alloys into near-net-shape parts using precision methods such as investment casting (lost-wax/silica-sol) and shell molding. In foundries and Manufacturing of metal castings, stainless alloys like CF8/CF8M (304/316 equivalents), 1.4408, and duplex grades deliver superior corrosion, heat, and wear resistance for demanding environments. Precision capabilities typically include ISO 8062-3 tolerances to CT6–CT8, surface roughness as fine as Ra 3.2–6.3 μm, and complex, thin-walled geometries that reduce downstream machining. NDT/QA options often encompass PMI, UT/MT, pressure testing, and EN 10204 3.1 material certification.

Welcome To Hebei Yuanda Trade Co., Ltd. manufactures engineered stainless steel cast components for OEMs in energy, fluid handling, food processing, marine, and petrochemical sectors. By combining robust tooling design, gating simulation, and CNC machining, Yuanda helps B2B decision makers shorten development cycles while improving repeatability. A typical case involves a petrochemical valve body where switching to investment-cast 316 stainless reduced leak paths and machining time, enabling a faster PPAP and smoother ramp to volume production compared with legacy green sand metal casting for similar geometries.

Benefits & Use Cases of Stainless Steel Casting in Manufacturing of metal castings

Across Manufacturing of metal castings, Stainless Steel Casting is favored for pump bodies, valve housings, impellers, manifolds, food-grade fittings, instrumentation components, marine hardware, and high-temperature brackets. Compared with aluminum die casting or aluminium metal casting, stainless is selected when the application demands higher corrosion resistance, elevated-temperature performance, or hygiene compliance—particularly in chemical processing, water treatment, food and beverage, and offshore environments. Where green sand metal casting excels in large, low-cost shapes, investment-cast stainless delivers finer details, thinner walls, and tighter tolerances for complex, pressure-containing components.

Key advantages include near-net-shape complexity, reduced machining stock, excellent mechanical properties, and long service life with minimal coatings. With a well-engineered aluminum casting die you can produce light alloys at volume; however, when lifecycle cost, chloride resistance, or sterilization are critical, stainless castings often win on total value. Welcome To Hebei Yuanda Trade Co., Ltd. brings foundry expertise, DFM collaboration, sample-to-PPAP support, and global logistics, enabling OEMs to consolidate suppliers and accelerate launches without compromising quality or traceability.

Cost, Maintenance & User Experience

Total cost of ownership favors Stainless Steel Casting when factoring durability, uptime, and reduced secondary operations. Although initial part cost can be higher than light alloys, stainless typically eliminates coatings and frequent replacements, lowering maintenance and warranty exposure. Precision tooling and consistent pour control reduce scrap, while near-net-shape features minimize machining time. Over a multi-year lifecycle, these elements often translate into a strong ROI for B2B manufacturers managing high service costs or strict reliability targets.

Maintenance is straightforward: periodic cleaning, optional passivation, and correct grade selection (e.g., 316 for chlorides) protect performance. Customers in the foundries and fluid-handling sectors commonly report fewer leak paths, better surface integrity, and tighter dimensional stability across batches. Welcome To Hebei Yuanda Trade Co., Ltd. supports this with process controls, traceable heat records, and in-house machining/finishing, helping OEMs standardize quality and reduce variation that previously drove excess buffer stock or rework.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping metal castings supply chains. Stainless steel is highly recyclable and often contains significant recycled content, supporting circularity and lower embodied carbon. Near-net-shape casting reduces machining chips and energy, while digital gating simulation and robust process capability curtail scrap. Buyers increasingly request EN 10204 3.1 certificates, RoHS/REACH compliance, and lifecycle transparency to align with corporate ESG programs and evolving regulations across the EU and North America.

Welcome To Hebei Yuanda Trade Co., Ltd. takes a forward-looking, eco-conscious approach—optimizing melt efficiency, reclaiming media where applicable, and engineering parts to reduce mass without compromising strength. Market momentum favors corrosion-resistant solutions for water infrastructure, renewable energy balance-of-plant, and hygienic processing equipment. As some programs still rely on aluminum die casting or green sand metal casting for cost or weight, many are dual-sourcing with stainless for critical subassemblies to balance risk, resilience, and sustainability goals.

Conclusion on Stainless Steel Casting from Welcome To Hebei Yuanda Trade Co., Ltd.

For manufacturers and foundries, Stainless Steel Casting delivers the right mix of precision, strength, and corrosion resistance to outperform alternatives in demanding applications. Whether complementing aluminium metal casting for lightweight parts or replacing coatings and multi-step assemblies, stainless provides dependable lifecycle value. Welcome To Hebei Yuanda Trade Co., Ltd. stands out for engineering support, consistent quality, and reliable delivery across global programs.

- Contact us: email: info@ydcastings.com

- Visit our website: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025