Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

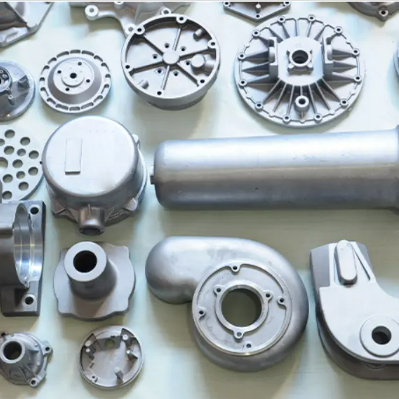

Metal Castings | Custom, Tight-Tolerance, Rapid Delivery

Metal Castings is a key solution in the manufacturing industry, specifically within foundries and Aluminum casting manufacturing. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Metal Castings Overview

- Benefits & Use Cases of Metal Castings in Aluminum casting manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Metal Castings from Welcome To Hebei Yuanda Trade Co., Ltd.

Metal Castings Overview

Metal castings are the backbone of modern manufacturing, transforming molten metal into precise, repeatable components with the strength, heat resistance, and dimensional accuracy required by industrial applications. In foundries specializing in Aluminum casting manufacturing, processes such as aluminum die casting, gravity casting, and green sand metal casting deliver parts for housings, brackets, impellers, enclosures, and complex geometry components. Across industries, buyers value the versatility of aluminium metal casting for its lightweight performance and corrosion resistance, while stainless steel casting is trusted for high-temperature and high-load environments.

From a technical standpoint, choosing between an aluminum casting die solution and sand or gravity casting depends on volume, tolerance, surface finish, and mechanical requirements. Die casting excels at high throughput and near-net shapes; sand casting suits larger, lower-volume parts and rapid design changes; gravity casting balances tooling cost with better density and finishes. Welcome To Hebei Yuanda Trade Co., Ltd. supports engineers with DFM reviews, material selection guidance (e.g., Al-Si-Mg alloys for strength, Al-Si for fluidity), and value-added operations such as heat treatment, machining, and protective coatings—helping B2B decision makers match process capability with product requirements.

Benefits & Use Cases of Metal Castings in Aluminum casting manufacturing

In Aluminum casting manufacturing, metal castings enable high-strength, lightweight components for automotive, industrial automation, energy, HVAC, and transportation applications. Typical use cases include pump bodies, motor housings, gearbox covers, heat-dissipating enclosures, and structural brackets where weight reduction and thermal performance are critical. Aluminum die casting offers fast cycle times and excellent repeatability; green sand metal casting provides design freedom and economical prototyping; and gravity casting delivers sound, low-porosity parts with improved mechanical properties.

- Design efficiency: Near-net shapes reduce machining, while an optimized aluminum casting die shortens time-to-market and stabilizes quality.

- Performance: Aluminium metal casting combines low weight with good tensile strength and thermal conductivity—ideal for electrification and lightweight platforms.

- Scalability: Flexible process selection supports pilot runs through mass production; stainless steel casting is available where higher temperature or abrasion resistance is required.

Welcome To Hebei Yuanda Trade Co., Ltd. brings practical foundry know-how, proactive DFM collaboration, and reliable project management—helping OEMs, Tier-1s, and equipment manufacturers align specifications, tooling, and QA plans to achieve consistent outcomes across global programs.

Cost, Maintenance & User Experience

For B2B buyers, total cost of ownership is shaped by tooling strategy, process yield, machining content, and logistics. Metal castings produced via aluminum die casting typically carry higher upfront tooling costs but deliver lower piece prices at volume. Green sand metal casting reduces tooling investment for low-to-mid volumes and engineering changes. A well-engineered aluminum casting die, paired with robust process control and secondary operations, minimizes rework, scrap, and lead-time variability—improving ROI across the product lifecycle.

Maintenance considerations center on tooling care, consistent melting/degassing practices, and inspection routines that preserve dimensional stability and surface quality. Customers in the foundries sector value clear PPAP-style documentation, traceable materials, and in-process inspection plans. Welcome To Hebei Yuanda Trade Co., Ltd. focuses on these fundamentals—DFM reviews, capability studies, and fit-for-purpose packaging—so users experience fewer line interruptions, predictable delivery, and components that integrate cleanly with downstream assembly and finishing.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping sourcing decisions for metal castings. Aluminum’s recyclability and favorable strength-to-weight ratio support lower lifetime emissions and energy use, while process innovations—such as sand reclamation in green sand metal casting, efficient melt practices, and optimized gating—reduce waste and resource consumption. Regulatory expectations around material traceability, responsible sourcing, and environmental reporting are expanding, influencing how enterprises qualify suppliers and plan long-term programs.

Market trends include ongoing light-weighting, electrification, and the integration of simulation-driven DFM to compress development cycles. Welcome To Hebei Yuanda Trade Co., Ltd. approaches sustainability pragmatically—prioritizing material efficiency, stable quality, and process repeatability that naturally cut waste and energy per part. By aligning casting process selection (aluminum die casting, gravity, or sand) with the product’s functional needs, the company helps customers meet performance targets while advancing corporate ESG goals.

Conclusion on Metal Castings from Welcome To Hebei Yuanda Trade Co., Ltd.

Metal castings remain essential to manufacturing, enabling precise, durable parts across demanding environments. Whether your program calls for aluminium metal casting with a high-speed aluminum casting die, flexible green sand metal casting for development, or stainless steel casting for elevated service conditions, Welcome To Hebei Yuanda Trade Co., Ltd. delivers a dependable, engineering-driven partnership from DFM through production. Count on disciplined quality, responsive project management, and a process fit to your cost and performance goals. Contact us: email: info@ydcastings.com — Visit our website: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025