Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

Automotive Metal Casting Technologies-Hebei Yuanda Trade Co., Ltd.|Precision Engineering&Lightweight Solutions

Automotive manufacturing has undergone a transformative evolution, driven by advancements in metal casting and processing technologies. These innovations are pivotal in enhancing vehicle performance, safety, and sustainability. This article explores the latest developments in automotive parts production, focusing on casting techniques, material science, and design optimization. By leveraging automobile accessories from Hebei Yuanda Trade Co., Ltd., manufacturers can achieve unprecedented precision and efficiency.

Understanding Modern Automotive Casting Technologies

Automotive parts production relies heavily on casting technologies, which account for 15-20% of all vehicle components. This process is critical for creating power system components and structural parts. Advanced casting methods, particularly in Europe and the United States, demonstrate superior quality and efficiency. These regions utilize digital technologies to reduce casting scrap rates to 2-5%, compared to China's traditional black casting methods, which lag behind in technical sophistication (NIST).

Casting Technology: Precision and Efficiency

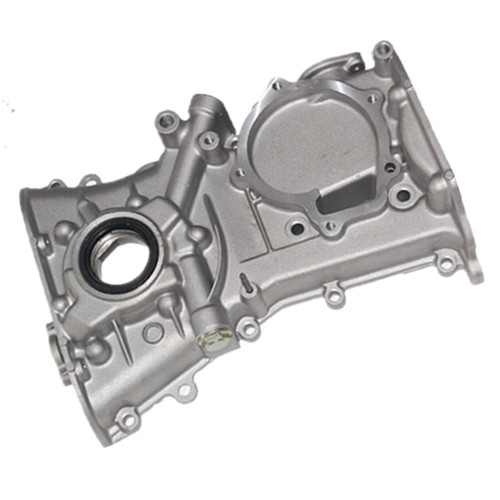

Casting involves shaping molten metal into intricate forms, forming the backbone of automotive components. Modern techniques prioritize dimensional accuracy and surface quality, ensuring seamless integration with other vehicle systems. The adoption of digital design tools has significantly improved process control, minimizing waste and maximizing output.

For further insights into casting technologies, visit automobile accessories at Hebei Yuanda Trade Co., Ltd.

Die Casting: High-Performance Components

Die casting is a cornerstone of modern automotive manufacturing, enabling the production of complex parts with high dimensional accuracy. This process uses high-pressure metal injection into molds, resulting in components that meet stringent quality standards. Common materials include aluminum and zinc alloys, chosen for their strength, durability, and lightweight properties. These alloys enhance vehicle safety and reliability, making them ideal for critical applications.

Explore automotive electric water pumps and other precision-engineered components from Hebei Yuanda Trade Co., Ltd.

Semi-Solid Processing: Lightweight Solutions

Semi-solid processing represents a breakthrough in automotive manufacturing, particularly for magnesium and aluminum alloys. This technology allows for thinner casting walls (1-1.5mm) and improved material efficiency. Magnesium alloys, with their high strength-to-weight ratio and corrosion resistance, are becoming increasingly popular for lightweight vehicle designs. According to NIST, the global adoption of magnesium die casting is growing at a 25% annual rate, driven by environmental and performance benefits.

Discover the advantages of engine manifolds and other semi-solid processed parts.

Integrated Design: Redefining Automotive Engineering

Integrated design strategies are revolutionizing automotive manufacturing by reducing part complexity and weight. Through structural optimization, manufacturers can create single-piece components that eliminate unnecessary machining processes. This approach not only lowers production costs but also enhances vehicle performance and sustainability.

Learn more about electric water pump for car solutions from Hebei Yuanda Trade Co., Ltd.

Technical Specifications of Automotive Parts

| Parameter | Einzelheiten |

|---|---|

| Material | ADC-12, A380 |

| Process | High-pressure casting |

| Weight Range | 0.5-2kg |

| Surface Finish | High precision, minimal defects |

| Applications | Engine manifolds, water pumps, structural components |

Applications Across the Automotive Industry

The advancements in casting technologies have broad applications, from powertrain components to interior systems. Key applications include:

- Engine Manifolds: High-performance casting ensures optimal airflow and fuel efficiency.

- Electric Water Pumps: Precision-engineered to enhance cooling system reliability.

- Structural Components: Lightweight yet durable designs improve vehicle safety and fuel economy.

Explore auto electric water pump solutions tailored for modern vehicles.

Company Background: Hebei Yuanda Trade Co., Ltd.

Based in China, Hebei Yuanda Trade Co., Ltd. is a leading provider of automotive parts and accessories. The company specializes in high-quality casting solutions, leveraging advanced technologies to meet global industry standards. With a focus on innovation and sustainability, Hebei Yuanda delivers products that combine precision engineering with cost-effectiveness.

Visit automobile accessories to discover the full range of products and services offered by Hebei Yuanda Trade Co., Ltd.

Conclusion: The Future of Automotive Manufacturing

The continuous evolution of metal casting and processing technologies is reshaping the automotive industry. By adopting advanced techniques like die casting, semi-solid processing, and integrated design, manufacturers can achieve higher efficiency, reduced environmental impact, and improved vehicle performance. Hebei Yuanda Trade Co., Ltd. exemplifies this progress, offering cutting-edge solutions that meet the demands of modern automotive engineering.

References

National Institute of Standards and Technology (NIST) - Information on advanced manufacturing technologies and standards.

Hebei Yuanda Trade Co., Ltd. - Automobile accessories and casting solutions.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025

Automotive Metal Casting Technologies-Hebei Yuanda Trade Co., Ltd.|Precision Engineering&Lightweight Solutions

Automotive manufacturing has undergone a transformative evolution, driven by advancements in metal casting and processing technologies. These innovations are pivotal in enhancing vehicle performance, safety, and sustainability. This article explores the latest developments in automotive parts production, focusing on casting techniques, material science, and design optimization. By leveraging automobile accessories from Hebei Yuanda Trade Co., Ltd., manufacturers can achieve unprecedented precision and efficiency.

Understanding Modern Automotive Casting Technologies

Automotive parts production relies heavily on casting technologies, which account for 15-20% of all vehicle components. This process is critical for creating power system components and structural parts. Advanced casting methods, particularly in Europe and the United States, demonstrate superior quality and efficiency. These regions utilize digital technologies to reduce casting scrap rates to 2-5%, compared to China's traditional black casting methods, which lag behind in technical sophistication (NIST).

Casting Technology: Precision and Efficiency

Casting involves shaping molten metal into intricate forms, forming the backbone of automotive components. Modern techniques prioritize dimensional accuracy and surface quality, ensuring seamless integration with other vehicle systems. The adoption of digital design tools has significantly improved process control, minimizing waste and maximizing output.

For further insights into casting technologies, visit automobile accessories at Hebei Yuanda Trade Co., Ltd.

Die Casting: High-Performance Components

Die casting is a cornerstone of modern automotive manufacturing, enabling the production of complex parts with high dimensional accuracy. This process uses high-pressure metal injection into molds, resulting in components that meet stringent quality standards. Common materials include aluminum and zinc alloys, chosen for their strength, durability, and lightweight properties. These alloys enhance vehicle safety and reliability, making them ideal for critical applications.

Explore automotive electric water pumps and other precision-engineered components from Hebei Yuanda Trade Co., Ltd.

Semi-Solid Processing: Lightweight Solutions

Semi-solid processing represents a breakthrough in automotive manufacturing, particularly for magnesium and aluminum alloys. This technology allows for thinner casting walls (1-1.5mm) and improved material efficiency. Magnesium alloys, with their high strength-to-weight ratio and corrosion resistance, are becoming increasingly popular for lightweight vehicle designs. According to NIST, the global adoption of magnesium die casting is growing at a 25% annual rate, driven by environmental and performance benefits.

Discover the advantages of engine manifolds and other semi-solid processed parts.

Integrated Design: Redefining Automotive Engineering

Integrated design strategies are revolutionizing automotive manufacturing by reducing part complexity and weight. Through structural optimization, manufacturers can create single-piece components that eliminate unnecessary machining processes. This approach not only lowers production costs but also enhances vehicle performance and sustainability.

Learn more about electric water pump for car solutions from Hebei Yuanda Trade Co., Ltd.

Technical Specifications of Automotive Parts

| Parameter | Einzelheiten |

|---|---|

| Material | ADC-12, A380 |

| Process | High-pressure casting |

| Weight Range | 0.5-2kg |

| Surface Finish | High precision, minimal defects |

| Applications | Engine manifolds, water pumps, structural components |

Applications Across the Automotive Industry

The advancements in casting technologies have broad applications, from powertrain components to interior systems. Key applications include:

- Engine Manifolds: High-performance casting ensures optimal airflow and fuel efficiency.

- Electric Water Pumps: Precision-engineered to enhance cooling system reliability.

- Structural Components: Lightweight yet durable designs improve vehicle safety and fuel economy.

Explore auto electric water pump solutions tailored for modern vehicles.

Company Background: Hebei Yuanda Trade Co., Ltd.

Based in China, Hebei Yuanda Trade Co., Ltd. is a leading provider of automotive parts and accessories. The company specializes in high-quality casting solutions, leveraging advanced technologies to meet global industry standards. With a focus on innovation and sustainability, Hebei Yuanda delivers products that combine precision engineering with cost-effectiveness.

Visit automobile accessories to discover the full range of products and services offered by Hebei Yuanda Trade Co., Ltd.

Conclusion: The Future of Automotive Manufacturing

The continuous evolution of metal casting and processing technologies is reshaping the automotive industry. By adopting advanced techniques like die casting, semi-solid processing, and integrated design, manufacturers can achieve higher efficiency, reduced environmental impact, and improved vehicle performance. Hebei Yuanda Trade Co., Ltd. exemplifies this progress, offering cutting-edge solutions that meet the demands of modern automotive engineering.

References

National Institute of Standards and Technology (NIST) - Information on advanced manufacturing technologies and standards.

Hebei Yuanda Trade Co., Ltd. - Automobile accessories and casting solutions.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025