Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

Automotive Electric Water Pump - Hebei Yuanda Trade Co., Ltd.|Precision Casting, Die Casting

Automotive accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of high-performance components. From engine manifolds to electric water pumps, the integration of advanced manufacturing techniques ensures precision, durability, and efficiency. This article explores the latest developments in automotive metal casting, highlighting the automotive electric water pump, engine manifolds, and other key components, while emphasizing the role of Hebei Yuanda Trade Co., Ltd. in driving innovation. Additionally, we reference the National Institute of Standards and Technology (NIST) to underscore the importance of standardized manufacturing practices.

Key Technologies in Automotive Metal Casting and Processing

Casting Technology: Precision and Efficiency

Casting is a foundational process in automotive part production, accounting for approximately 15-20% of all components. This method is particularly vital for manufacturing power system key components and structural elements. According to NIST, advanced casting techniques are essential for achieving dimensional accuracy and minimizing waste. In developed countries like the United States and Europe, digital technologies have elevated casting processes, reducing scrap rates to 2-5%. In contrast, China's casting industry, while producing large volumes, often lags in technical sophistication and value-added output.

Die Casting: Enhancing Precision and Durability

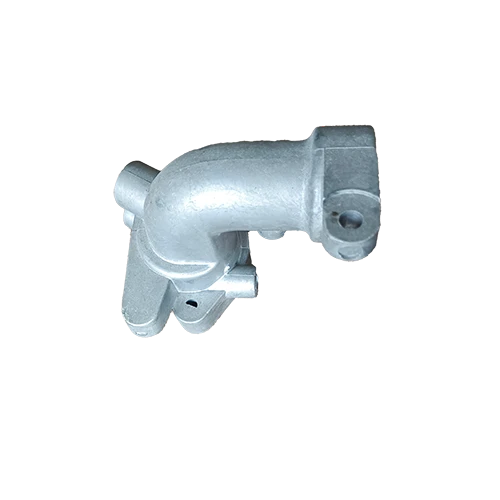

Die casting is a cornerstone of modern automotive manufacturing, utilizing high-pressure metal injection to create precise components. This process ensures dimensional accuracy and surface quality, enabling parts to fit seamlessly with other vehicle components. Materials like aluminum and zinc alloys are commonly used, offering excellent strength and durability. The automotive electric water pump is a prime example, leveraging die casting to achieve lightweight yet robust construction. As noted by NIST, such techniques align with industry standards for precision manufacturing, supporting the development of safer and more reliable vehicles.

Semi-Solid Processing: Lightweight Solutions for Modern Vehicles

Semi-solid processing represents a cutting-edge approach, particularly for magnesium and aluminum alloy castings. This technology addresses challenges in die-casting magnesium alloys, enabling thinner walls (1-1.5mm) and improved structural integrity. The electric water pump for car benefits from this innovation, achieving a balance between weight reduction and performance. As highlighted by NIST, advancements in semi-solid processing are critical for meeting the automotive industry's demand for lightweight materials, which directly contribute to fuel efficiency and reduced emissions.

Advantages of Modern Automotive Accessories

Lightweight and High-Performance Design

Integrated design strategies are revolutionizing automotive manufacturing by reducing part weight and minimizing machining processes. For instance, engine manifolds are now crafted using optimized designs that enhance airflow efficiency while cutting down on material waste. This approach not only improves vehicle performance but also aligns with global trends toward sustainability. As per NIST, lightweight materials are pivotal in achieving the energy efficiency goals set by modern automotive standards.

Environmental and Economic Benefits

Advanced casting technologies significantly reduce environmental impact by lowering scrap rates and energy consumption. The auto electric water pump exemplifies this, as its production process minimizes pollution while maintaining high-quality output. Additionally, these innovations reduce production costs, making high-performance components more accessible. NIST emphasizes that such sustainable practices are essential for the long-term viability of the automotive industry.

Technical Specifications of Automotive Accessories

| Material | Process | Specification |

|---|---|---|

| ADC-12, A380 | High-pressure casting | 0.5-2kg |

Applications of Automotive Accessories

Powertrain Components

Casting technologies are indispensable in producing powertrain components, such as engine blocks and transmission cases. These parts require high precision and durability to withstand extreme operating conditions. The automotive electric water pump is a critical component in cooling systems, ensuring optimal engine performance under varying temperatures.

Structural and Safety-Critical Parts

Die casting and semi-solid processing are also used for structural components like suspension parts and chassis elements. These parts must meet stringent safety standards, and the use of advanced materials ensures they can endure mechanical stress. The engine manifolds are another example, designed to optimize combustion efficiency and reduce emissions.

About Hebei Yuanda Trade Co., Ltd.

As a leading supplier of automotive accessories, Hebei Yuanda Trade Co., Ltd. specializes in high-quality metal casting and processing solutions. The company's commitment to innovation is evident in its adoption of cutting-edge technologies, such as automotive electric water pumps and engine manifolds. By aligning with international standards, Hebei Yuanda ensures its products meet the rigorous demands of global automotive markets.

Conclusion

The evolution of metal casting and processing technologies is reshaping the automotive industry, enabling the production of lighter, stronger, and more sustainable components. From electric water pumps for cars to engine manifolds, these innovations are driven by companies like Hebei Yuanda Trade Co., Ltd., which prioritize quality and efficiency. As highlighted by NIST, adherence to standardized manufacturing practices is crucial for maintaining the reliability and safety of modern vehicles. By embracing these advancements, the automotive sector can continue to meet the challenges of a rapidly changing market.

References

National Institute of Standards and Technology (NIST). (n.d.). Manufacturing and Standards. Retrieved from https://www.nist.gov/.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025

Automotive Electric Water Pump - Hebei Yuanda Trade Co., Ltd.|Precision Casting, Die Casting

Automotive accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of high-performance components. From engine manifolds to electric water pumps, the integration of advanced manufacturing techniques ensures precision, durability, and efficiency. This article explores the latest developments in automotive metal casting, highlighting the automotive electric water pump, engine manifolds, and other key components, while emphasizing the role of Hebei Yuanda Trade Co., Ltd. in driving innovation. Additionally, we reference the National Institute of Standards and Technology (NIST) to underscore the importance of standardized manufacturing practices.

Key Technologies in Automotive Metal Casting and Processing

Casting Technology: Precision and Efficiency

Casting is a foundational process in automotive part production, accounting for approximately 15-20% of all components. This method is particularly vital for manufacturing power system key components and structural elements. According to NIST, advanced casting techniques are essential for achieving dimensional accuracy and minimizing waste. In developed countries like the United States and Europe, digital technologies have elevated casting processes, reducing scrap rates to 2-5%. In contrast, China's casting industry, while producing large volumes, often lags in technical sophistication and value-added output.

Die Casting: Enhancing Precision and Durability

Die casting is a cornerstone of modern automotive manufacturing, utilizing high-pressure metal injection to create precise components. This process ensures dimensional accuracy and surface quality, enabling parts to fit seamlessly with other vehicle components. Materials like aluminum and zinc alloys are commonly used, offering excellent strength and durability. The automotive electric water pump is a prime example, leveraging die casting to achieve lightweight yet robust construction. As noted by NIST, such techniques align with industry standards for precision manufacturing, supporting the development of safer and more reliable vehicles.

Semi-Solid Processing: Lightweight Solutions for Modern Vehicles

Semi-solid processing represents a cutting-edge approach, particularly for magnesium and aluminum alloy castings. This technology addresses challenges in die-casting magnesium alloys, enabling thinner walls (1-1.5mm) and improved structural integrity. The electric water pump for car benefits from this innovation, achieving a balance between weight reduction and performance. As highlighted by NIST, advancements in semi-solid processing are critical for meeting the automotive industry's demand for lightweight materials, which directly contribute to fuel efficiency and reduced emissions.

Advantages of Modern Automotive Accessories

Lightweight and High-Performance Design

Integrated design strategies are revolutionizing automotive manufacturing by reducing part weight and minimizing machining processes. For instance, engine manifolds are now crafted using optimized designs that enhance airflow efficiency while cutting down on material waste. This approach not only improves vehicle performance but also aligns with global trends toward sustainability. As per NIST, lightweight materials are pivotal in achieving the energy efficiency goals set by modern automotive standards.

Environmental and Economic Benefits

Advanced casting technologies significantly reduce environmental impact by lowering scrap rates and energy consumption. The auto electric water pump exemplifies this, as its production process minimizes pollution while maintaining high-quality output. Additionally, these innovations reduce production costs, making high-performance components more accessible. NIST emphasizes that such sustainable practices are essential for the long-term viability of the automotive industry.

Technical Specifications of Automotive Accessories

| Material | Process | Specification |

|---|---|---|

| ADC-12, A380 | High-pressure casting | 0.5-2kg |

Applications of Automotive Accessories

Powertrain Components

Casting technologies are indispensable in producing powertrain components, such as engine blocks and transmission cases. These parts require high precision and durability to withstand extreme operating conditions. The automotive electric water pump is a critical component in cooling systems, ensuring optimal engine performance under varying temperatures.

Structural and Safety-Critical Parts

Die casting and semi-solid processing are also used for structural components like suspension parts and chassis elements. These parts must meet stringent safety standards, and the use of advanced materials ensures they can endure mechanical stress. The engine manifolds are another example, designed to optimize combustion efficiency and reduce emissions.

About Hebei Yuanda Trade Co., Ltd.

As a leading supplier of automotive accessories, Hebei Yuanda Trade Co., Ltd. specializes in high-quality metal casting and processing solutions. The company's commitment to innovation is evident in its adoption of cutting-edge technologies, such as automotive electric water pumps and engine manifolds. By aligning with international standards, Hebei Yuanda ensures its products meet the rigorous demands of global automotive markets.

Conclusion

The evolution of metal casting and processing technologies is reshaping the automotive industry, enabling the production of lighter, stronger, and more sustainable components. From electric water pumps for cars to engine manifolds, these innovations are driven by companies like Hebei Yuanda Trade Co., Ltd., which prioritize quality and efficiency. As highlighted by NIST, adherence to standardized manufacturing practices is crucial for maintaining the reliability and safety of modern vehicles. By embracing these advancements, the automotive sector can continue to meet the challenges of a rapidly changing market.

References

National Institute of Standards and Technology (NIST). (n.d.). Manufacturing and Standards. Retrieved from https://www.nist.gov/.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025