Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

what is die casting

What is Die Casting?

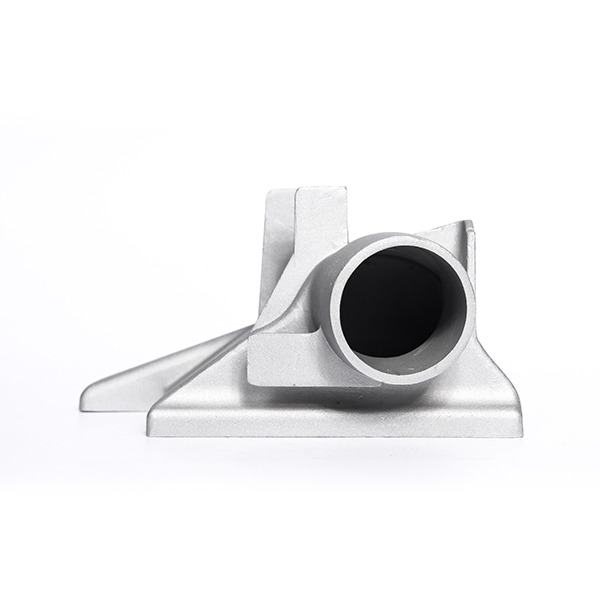

Die casting is a versatile manufacturing process that allows for the precise molding of metal parts using high-pressure techniques. This process is primarily used in the production of non-ferrous metals, such as aluminum, zinc, and magnesium, to create complex shapes and parts with minimal waste. Die casting is highly beneficial for producing large quantities of intricate designs, making it an essential method in various industries, including automotive, aerospace, electronics, and consumer goods.

What is Die Casting?

Once the die is prepared, molten metal is injected into the cavity at high pressure. This injection is facilitated by a machine that maintains the temperature of the molten metal, ensuring it flows smoothly into all parts of the mold. The high pressure forces the molten metal to fill the cavity completely, reducing the likelihood of defects and ensuring a tight fit for complex geometries. After the metal cools and solidifies, the die is opened, and the finished part is ejected.

what is die casting

One of the significant advantages of die casting is the ability to produce parts with thin walls and complex shapes, which would be challenging or impossible to achieve with other manufacturing methods. Additionally, die casting offers excellent dimensional stability and surface finish, which often reduces or eliminates the need for further machining or finishing operations. This efficiency not only speeds up production cycles but also helps lower overall manufacturing costs.

However, die casting is not without its challenges. The initial setup cost for creating the die can be significant, making the process more economical for high-volume production runs. Moreover, some limitations exist regarding the types of metals that can be used and the tolerances achievable. Despite these challenges, die casting continues to be a preferred method for many manufacturers due to its advantages in speed, precision, and versatility.

In summary, die casting is a highly effective manufacturing technique that allows for the rapid production of complex metal parts with exceptional accuracy and surface finish. Its applications span numerous industries, making it an essential component of modern manufacturing processes. As technology evolves, die casting will likely continue to play a vital role in meeting the demands of an ever-changing market.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025