Mobile:+86-311-808-126-83

Email:info@ydcastings.com

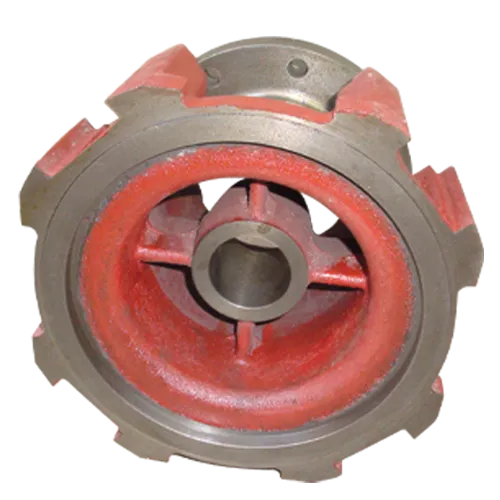

water pump impeller

The water pump impeller stands as a vital component in fluid circulation systems, predominantly used in various industries such as automotive, agricultural, and industrial applications. Understanding the functionality, types, and maintenance of water pump impellers not only optimizes their performance but also extends their lifespan, enhancing their overall efficiency in any mechanical setup.

An impeller's primary role is to convert rotational energy into the energy required to pump water, making it the heart of any water pump system. This conversion is achieved by accelerating the fluid outwards from the center of rotation. The impellers are generally disc-shaped with vanes that play a crucial role in moving the fluid efficiently. These vanes are strategically designed and angled to facilitate the outward flow of water, thereby minimizing energy loss and maximizing output.

Expertise in selecting the appropriate water pump impeller begins with understanding the different types available and the specific applications they cater to. Centrifugal impellers are predominantly used for standard applications, providing linear flow output with increased pressure. Axial flow impellers, on the other hand, are utilized in applications requiring high flow rates at a lower pressure, ideal for processes like circulation and chemical mixing. Radial impellers are known for their high-pressure output at lower flow rates, often used in specialized industries requiring precise fluid control.

Ensuring authoritative knowledge on water pump impellers means recognizing the materials from which they are constructed. Common materials include cast iron, for its durability and cost-effectiveness; stainless steel, for its corrosion resistance and hygiene in food and pharmaceutical applications; bronze, for its marine water compatibility; and thermoplastics, suitable for low-stress environments. The choice of material significantly impacts the impeller’s performance, durability, and suitability for specific applications.

water pump impeller

Trustworthiness in water pump impeller performance can be guaranteed through routine maintenance and inspection. Regular checks for wear and tear on the impeller blades, as well as cleaning any debris, ensure efficient operation and prevent premature failure. It is also important to verify the alignment and balance of the impeller to avoid unnecessary vibrations that can lead to mechanical issues.

Incorporating real-world experience, professionals advise maintaining a spare impeller in systems critical for continuous operation, minimizing downtime during replacements. Further enhancing reliability, many experts recommend investing in high-quality impellers from reputable manufacturers, as they provide warranty and support, ensuring consistent performance and peace of mind.

Overall, by leveraging expertise in selecting the right type, material, and maintenance routine, optimizing the performance of a water pump impeller becomes seamless. It not only solidifies the operation's efficiency but also extends the lifespan and reliability of the water pump system. When combined with authoritative guidance and trustworthy practices, a well-chosen impeller can significantly impact the productivity and safety of fluid management systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025