Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Functionality of Water Motor Impellers in Fluid Dynamics Applications

The Water Motor Impeller An Essential Component in Fluid Dynamics

Water motor impellers play a crucial role in various applications, ranging from industrial machinery to household appliances. These devices are designed to enhance fluid flow and increase the efficiency of machines that rely on water as a primary medium. Understanding the design, functionality, and applications of water motor impellers is essential for anyone involved in engineering, fluid mechanics, or related fields.

What is a Water Motor Impeller?

An impeller is a rotor-like component designed to transfer energy from a motor to the fluid, facilitating movement. In water motors, impellers are typically found in pumps, turbines, and various hydraulic systems. They are shaped like blades or fans, which rotate to create a pressure difference that moves water. The design of the impeller is critical to its efficiency, as it must convert the kinetic energy of rotation into the kinetic energy of the water.

How Do Water Motor Impellers Work?

Impellers work by utilizing centrifugal force. As the impeller spins, it pushes water outward, creating a low-pressure zone at the center. This difference in pressure causes water to be drawn in through the inlet, allowing the flow to be directed towards the desired outlet. The performance of an impeller is influenced by its size, shape, and rotational speed. For instance, larger impellers can move more fluid but may require more power to operate.

The efficiency of a water motor impeller is measured by its ability to convert input energy into hydraulic energy

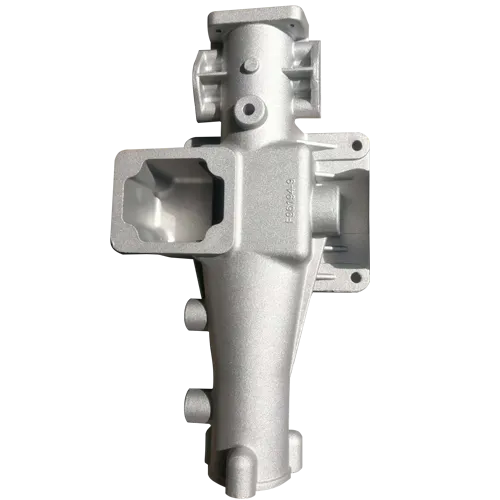

. Factors such as impeller design, material, and fluid viscosity affect this efficiency. For example, an impeller made from corrosion-resistant materials will last longer and perform better in harsh environments, reducing maintenance costs.water motor impeller

Applications of Water Motor Impellers

Water motor impellers have diverse applications across various industries. In the agricultural sector, they are used in irrigation systems to move water efficiently to crops. This ensures optimal growth conditions and maximizes yield. In the industrial sphere, water impellers are integral to cooling systems, where they help dissipate excess heat generated in machinery.

In the realm of energy generation, specifically in hydropower plants, turbine impellers convert the energy of flowing water into electricity. These systems are crucial for sustainable energy production, showcasing the importance of water motor impellers in modern energy solutions.

Additionally, in the residential sector, impellers are found in household appliances such as washing machines and dishwashers, where they aid in the effective washing of clothes and dishes. The design and technology used in these household devices directly impact their performance and energy consumption.

Future of Water Motor Impellers

With advancements in materials science and fluid dynamics, the future of water motor impellers looks promising. Innovations such as 3D printing allow for more complex and optimized designs that can enhance efficiency and reduce costs. Moreover, the increasing emphasis on sustainability and energy efficiency drives research into new impeller technologies that use less energy and have longer service lives.

In conclusion, water motor impellers are vital components in a wide array of applications, playing an essential role in fluid dynamics. Their ability to enhance flow efficiency and adapt to various operational demands makes them indispensable in both industrial and domestic settings. Understanding their function, design, and future developments is critical for engineers and manufacturers focused on improving fluid transport systems and contributing to sustainable technologies. As we move forward, the evolution of water motor impellers will undoubtedly pave the way for more innovative solutions in fluid mechanics.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025