Mobile:+86-311-808-126-83

Email:info@ydcastings.com

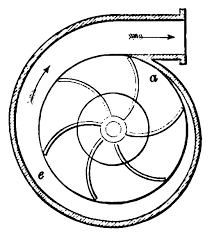

vortex casing in centrifugal pump

Vortex Casing in Centrifugal Pumps Design and Performance Implications

Centrifugal pumps are vital components in many industries, delivering fluids efficiently under a wide range of conditions. A crucial aspect of centrifugal pump design is the casing, which significantly influences the pump's performance, efficiency, and operational stability. One innovative design feature that has gained attention in recent years is the vortex casing. This article examines the concept of vortex casing in centrifugal pumps, its benefits, and its implications for pump performance.

Understanding Vortex Casing

Vortex casing refers to a specialized design of the pump casing that promotes the formation of a vortex flow pattern within the pump. This design diverges from the conventional casing geometry that primarily focuses on linear flow. In a vortex casing, the internal geometry is optimized to create a swirling motion of the fluid, which assists in managing flow separation and improving energy transfer.

The primary objective of a vortex casing is to enhance hydraulic performance by utilizing the advantages of vortex flow. The swirling motion reduces turbulence and energy losses associated with conventional flow patterns. Moreover, this design can lead to improved efficiency under varying operational conditions, making pumps more adaptable in diverse applications.

Benefits of Vortex Casing

1. Enhanced Efficiency Vortex casings have demonstrated superior efficiency compared to traditional pump casings. By minimizing flow separation and turbulence, these designs allow for smoother energy transfer from the impeller to the fluid. This efficiency translates to reduced energy consumption, which is critically important in industrial applications where operational costs are a concern.

2. Improved NPSH Performance The Net Positive Suction Head (NPSH) is a significant factor in pump design, directly impacting cavitation. Vortex casings can provide enhanced NPSH performance by reducing local pressure drops at the inlet. This feature is particularly beneficial in processes involving volatile liquids or conditions prone to cavitation.

vortex casing in centrifugal pump

3. Reduced Noise and Vibration The swirling flow pattern in vortex casings contributes to a more stable flow, leading to reduced noise and vibration levels. This characteristic is essential in applications where noise pollution is a concern, such as in residential or hospital settings. Moreover, lower vibration levels can extend the life of the pump and reduce maintenance costs.

4. Broad Operating Range Vortex casing designs allow centrifugal pumps to operate efficiently over a broader range of flow rates and heads. This flexibility makes these pumps more versatile and suitable for various applications, from water supply systems to industrial processes.

5. Improved Solid Handling In applications where solids are present in the fluid, vortex casings can enhance the pump's ability to handle these particles. The swirling action helps in maintaining solid particles in suspension, minimizing the risk of clogging or wear on internal components.

Design Considerations

While the advantages of vortex casing are significant, implementing this design requires careful consideration. The internal geometry must be precisely engineered to achieve the desired vortex flow without compromising structural integrity or introducing excessive pressure losses. Computational fluid dynamics (CFD) simulations are often employed during the design phase to predict flow behavior and optimize casing shapes.

Furthermore, the specific application and fluid characteristics must be taken into account. For instance, pumps intended for low-viscosity fluids may require different vortex casing designs compared to those handling slurries or highly viscous substances. Collaborating with pump manufacturers and engineers can ensure the optimal design tailored to specific operational needs.

Conclusion

Vortex casing represents an innovative advancement in centrifugal pump design, offering numerous benefits including enhanced efficiency, improved NPSH performance, reduced noise, and a broader operating range. As industries continue to seek more efficient and reliable pumping solutions, the adoption of vortex casing technology is likely to grow. By understanding the implications of this design feature, engineers and decision-makers can make informed choices that lead to improved operational performance and reduced energy consumption in their pumping systems. As technology evolves, the potential for vortex casings in other applications may also be explored, further enhancing the role of centrifugal pumps in various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025