Mobile:+86-311-808-126-83

Email:info@ydcastings.com

metal pipe caps

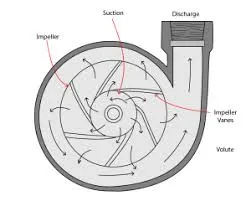

Volute case is a critical component of a centrifugal pump

A volute case, also known as a volute housing or volute chamber, is a component commonly used in centrifugal pumps. It is an essential part of the pump's casing and plays a crucial role in directing the flow of fluid as it moves through the pump. Here are some key points about volute cases:

1. **Function:** The primary function of a volute case is to convert the high-velocity, low-pressure fluid exiting the impeller of a centrifugal pump into low-velocity, high-pressure flow. In other words, it helps in increasing the pressure of the fluid while decreasing its velocity.

2. **Design:** Volute cases typically have a spiral or snail-shell shape. This spiral design allows the fluid to follow a curved path as it moves through the volute, which results in pressure buildup. The shape of the volute case is carefully engineered to maximize pump efficiency and performance.

3. **Material:** Volute cases are often made from materials that are corrosion-resistant and can withstand the operating conditions of the pump. Common materials include cast iron, stainless steel, and various alloys, depending on the application.

4. **Casting Process:** The casting process used to manufacture volute cases can vary but often involves methods like metal mold casting or gravity casting. These processes are chosen to ensure the casing has the necessary strength and durability.

5. **Attachment:** Volute cases are typically attached to the pump's impeller housing, creating a continuous flow path for the fluid. The impeller rotates inside the volute case, creating centrifugal force that drives the fluid outward toward the volute walls.

Volute Case

6. **Efficiency:** The design and quality of the volute case are crucial for pump efficiency. Well-designed volute cases minimize energy losses and maximize the conversion of kinetic energy into pressure energy.

7. **Maintenance:** Volute cases are designed for durability, but they can still be subject to wear and tear over time, particularly if the pump operates under challenging conditions. Regular maintenance and inspection are essential to ensure the continued performance of the pump.

8. **Applications:** Centrifugal pumps with volute cases are used in a wide range of applications, including water supply, wastewater treatment, irrigation, HVAC systems, and various industrial processes.

In summary, a volute case is a critical component of a centrifugal pump, responsible for converting kinetic energy into pressure energy as fluid moves through the pump. Its design, material, and quality are essential factors that impact the efficiency and performance of the pump.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025