Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

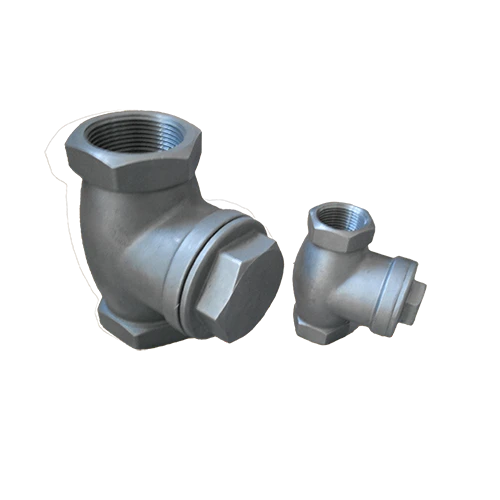

valve body

Understanding the Valve Body A Critical Component in Fluid Control Systems

The valve body is an essential component in various mechanical and hydraulic systems, particularly in the automotive and industrial sectors. Its primary function is to control the flow of fluids, whether they are oils, gases, or water, making it a vital part of systems that rely on precise movements and operations. This article delves into the intricacies of valve bodies, exploring their design, function, and significance in maintaining system efficiency and reliability.

What is a Valve Body?

A valve body can be defined as the main structure of a valve, housing the internal components that facilitate the control of fluid flow. Typically made from durable materials such as aluminum, cast iron, or stainless steel, valve bodies are engineered to withstand various pressures and temperatures. They come in several designs, depending on their application—ranging from simple on-off mechanisms to complex multi-port configurations that allow for intricate fluid management.

The Function of Valve Bodies

The primary role of a valve body is to regulate the flow of fluids through a system

. This is achieved through various mechanisms, including poppet valves, ball valves, and spool valves. Each type has its specific advantages and is chosen based on the requirements of the system. For instance, in an automotive transmission, the valve body directs hydraulic fluid to engage or disengage the gears, allowing for smooth and efficient shifting.In industrial applications, valve bodies manage the flow of liquids and gases in processes such as chemical manufacturing, water treatment, and HVAC systems. By precisely controlling fluid dynamics, valve bodies help maintain system stability and efficiency, reduce energy consumption, and enhance overall performance.

Design Considerations

When designing a valve body, several factors must be considered to ensure optimal performance. These include

valve body

1. Material Selection The material must be compatible with the types of fluids being controlled and capable of withstanding the operating conditions. For example, corrosive substances may require special coatings or materials to prevent deterioration.

2. Flow Characteristics The design should facilitate the desired flow rate while minimizing turbulence and pressure drops. Engineers often use computational fluid dynamics (CFD) simulations to optimize the flow paths within the valve body.

3. Size and Configuration The dimensions and layout of the valve body are crucial for fitting within the existing system and for accommodating the necessary connections for input and output ports.

4. Sealing Mechanisms Effective sealing is critical to prevent leaks and ensure the integrity of the fluid system. Various sealing materials and designs are employed, including O-rings, gaskets, and adaptive seals that maintain performance under varying pressures and temperatures.

The Importance of Maintenance

Like any mechanical component, valve bodies require regular maintenance to ensure their longevity and functionality. Over time, contaminants can build up, and seals may deteriorate, leading to suboptimal performance and potential failures. Routine inspections and timely replacements can mitigate these issues, ensuring that the valve body continues to operate effectively within the system.

Conclusion

In summary, the valve body is a cornerstone of fluid control systems across numerous industries. Its ability to regulate flow and optimize system performance cannot be overstated. By understanding the complexities of valve body design and function, businesses can better appreciate their significance and invest in the necessary maintenance to keep these vital components operating efficiently. As technology continues to advance, the design and functionality of valve bodies will likely evolve, making them even more integral to modern fluid management systems. Embracing innovation while adhering to best practices in maintenance will ensure that valve bodies remain reliable components in the machinery of our daily lives.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025