Mobile:+86-311-808-126-83

Email:info@ydcastings.com

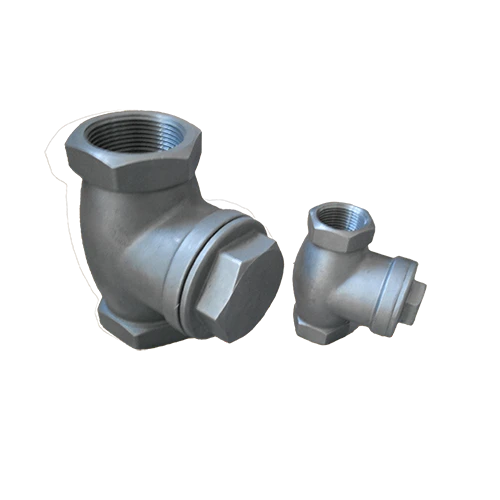

valve body

Understanding the Valve Body A Critical Component in Hydraulics

The valve body is a crucial element in various hydraulic systems, including automobiles, industrial machinery, and even aircraft. It serves as the central component that houses the valve mechanisms, which control the flow of fluids throughout a system. The significance of the valve body cannot be overstated, as it directly influences the performance, efficiency, and reliability of the entire hydraulic or pneumatic system.

A valve body comprises several parts, including the main housing, valve spools, and several ports. The main housing is typically constructed from durable materials, such as aluminum or cast iron, which can withstand high pressures and resist corrosion. The valve spools within the body serve the important function of directing fluid flow. They can move in and out of their respective ports to open or close pathways through which fluids can travel.

One of the most common applications of valve bodies is in automatic transmissions in vehicles. In this context, the valve body directs hydraulic fluid to various components like the clutches and bands, allowing the transmission to shift gears smoothly. When a driver accelerates or decelerates, sensors relay information to the transmission control module, instructing the valve body to engage the appropriate gear. A malfunction in the valve body can lead to erratic shifting behaviors or even transmission failure, underscoring its importance in automotive performance.

valve body

Moreover, in industrial applications, valve bodies regulate the flow of hydraulic fluid to different actuators and tools, ensuring they operate efficiently. Depending on the complexity of the system, a valve body may contain multiple valves, allowing for increased functionality and control. For instance, in manufacturing, a hydraulic press may utilize a sophisticated valve body to ensure precise control over the pressing strokes, leading to better product quality and operational efficiency.

Maintenance of the valve body is crucial for ensuring optimal performance. Regular inspections should check for signs of wear or damage, especially in high-use scenarios. Issues such as leaks can be early indicators of valve body failure, which can cause significant downtime and costly repairs. Furthermore, the proper use of hydraulic fluids is essential, as incompatible fluids can lead to corrosion and performance degradation.

In conclusion, the valve body plays an indispensable role in various hydraulic systems across multiple industries. Its ability to control fluid flow is vital to the operation of machinery, vehicles, and equipment. Understanding its functions and ensuring its proper maintenance can lead to improved efficiency, safety, and longevity of the systems it serves. As technology continues to advance, the design and functionality of valve bodies are likely to evolve, presenting new opportunities for innovation and improvement in hydraulic applications. Whether in automotive engineering or industrial manufacturing, the valve body remains a key player in the world of fluid dynamics.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025