Mobile:+86-311-808-126-83

Email:info@ydcastings.com

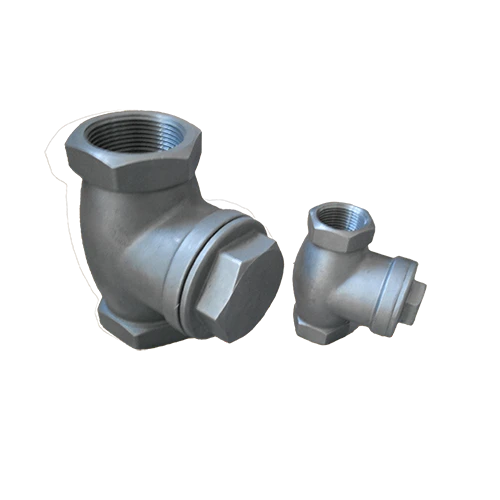

Creating a New Valve Concept for Enhanced Fluid Control Systems

The Versatility and Importance of Valves in Modern Engineering

Valves are crucial components in various engineering systems and industries. They play a significant role in controlling the flow of liquids and gases, ensuring that processes operate efficiently and safely. From simple household applications to complex industrial systems, valves come in numerous types and designs, each serving specific functions necessary for optimal operation.

At its core, a valve's primary purpose is to manage the flow of a fluid. This can include regulating, directing, or controlling the fluid's movement and pressure within a system. The need for valves can be observed in everyday life, from the tap on a sink that controls water flow to the intricate systems found in chemical processing plants or oil refineries.

One of the most common types of valves is the gate valve, which is designed to start or stop the flow of fluid. It operates by lifting a rectangular or circular gate out of the path of the fluid. While gate valves are effective for on-off control, they are not suitable for throttling because they can become damaged when partially open. In contrast, globe valves are specifically designed for throttling applications, enabling precise flow regulation through their adjustable mechanism.

Another prevalent type is the ball valve, known for its excellent sealing abilities and durability. The ball valve uses a spherical disc to control the flow, allowing for quick shut-off capabilities. These valves are widely used in applications that require tight sealing, making them ideal for industries such as water treatment and gas distribution.

valve

Additionally, check valves are essential for ensuring that fluid flows in only one direction. This prevents backflow, which can lead to contamination or damage within a system. Check valves are particularly important in applications like sewage systems and various chemical processes, where backflow could pose significant hazards.

The significance of valves extends beyond mere functionality; they also contribute to energy efficiency and safety. By regulating flow and pressure, valves reduce wear on pumps and other equipment, extending their lifespan and lowering maintenance costs. Furthermore, in industries where hazardous materials or high pressures are involved, valves are critical safety devices that prevent leaks and spills, protecting both workers and the environment.

Advancements in technology have also influenced valve design and functionality. Modern valves often incorporate smart technology, allowing for remote monitoring and control. Automated valves can significantly enhance operational efficiency by reducing the need for manual intervention, thus minimizing the risk of human error.

In conclusion, valves are indispensable in modern engineering across various industries, from water management to oil and gas and manufacturing. Their ability to control fluid flow and pressure not only facilitates smooth and efficient operations but also enhances safety and energy conservation. As technology continues to evolve, so too will the design and application of valves, making them an ever more vital component in the infrastructure of the future. Through continuous innovation, the role of valves will undoubtedly expand, meeting the dynamic demands of an increasingly interconnected and industrialized world.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025