Mobile:+86-311-808-126-83

Email:info@ydcastings.com

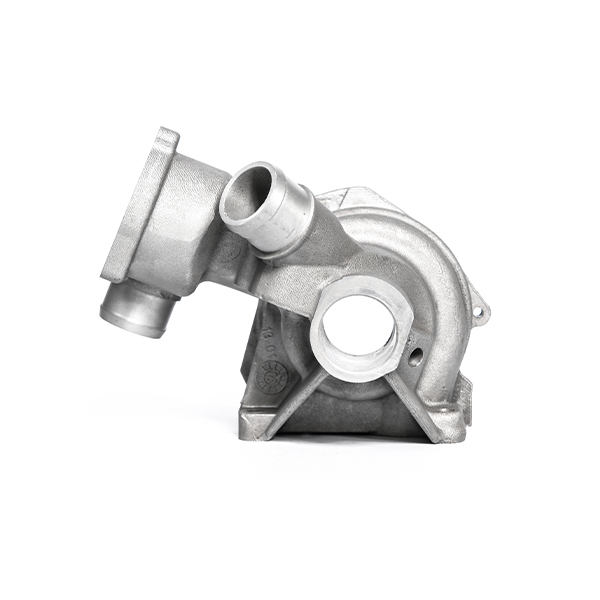

Understanding the Importance of Turbocharger Housings in Engine Performance Optimization

Understanding Turbocharger Housings A Comprehensive Overview

In the world of automotive engineering, turbocharging has become synonymous with enhanced performance and improved fuel efficiency. Central to this technology is the turbocharger housing, a vital component that plays a significant role in the overall functioning of a turbocharged engine. This article aims to delve into the purpose, design, and significance of turbocharger housings in modern engines.

What is a Turbocharger Housing?

The turbocharger housing is the outer shell of the turbocharger unit that encases its internal components, including the turbine and compressor. Essentially, there are two main sections to the housing the turbine housing and the compressor housing. The turbine housing is attached to the exhaust manifold and is responsible for directing the exhaust gases into the turbine wheel, which drives the compressor wheel located in the compressor housing.

The Role of Turbocharger Housings

Turbocharger housings serve several critical functions

1. Structural Support The housing provides structure and support, ensuring that the internal components are correctly aligned and positioned for optimal operation. This structural integrity is vital during high-speed rotation, where components can experience significant stress.

2. Heat Management Turbochargers operate at extremely high temperatures due to the exhaust gases that flow through the turbine housing. The materials used in the housing are specifically chosen for their ability to withstand high temperatures, preventing deformation and ensuring longevity. Additionally, some designs incorporate thermal barrier coatings to further enhance heat resistance.

turbo charger housing

3. Flow Dynamics The design of the housing plays a crucial role in ensuring efficient flow of both exhaust gases and compressed air. Turbocharger housings are meticulously engineered to minimize turbulence and losses, which directly impacts the efficiency of the turbocharger. Properly shaped housings help maximize the energy extracted from the exhaust gases, boosting overall engine performance.

4. Boost Control Many turbocharger systems feature wastegates integrated into the housing. The wastegate regulates boost pressure by diverting some exhaust flow away from the turbine when the desired boost pressure is reached. This control mechanism is essential for ensuring that the engine does not experience excessive boost, which can lead to mechanical failure.

Material Considerations

The materials used in turbocharger housings are crucial for their performance. Cast iron and stainless steel are common materials due to their strength and heat resistance. However, advancements in materials science have introduced options like high-nickel alloys and ceramic materials, which offer even greater durability and thermal stability. The choice of materials can impact not only performance but also weight, which is an essential factor in performance-oriented applications.

Customization and Aftermarket Options

The aftermarket industry has embraced turbocharger housings, offering customizable options that cater to enthusiasts seeking improved performance. Upgraded housings can provide better airflow, reduced weight, and enhanced thermal management. Enthusiasts often replace factory housings with high-performance options to achieve higher boost levels, faster spool times, and overall improved engine response.

Conclusion

In conclusion, the turbocharger housing is an indispensable component in turbocharged engines, contributing to the overall efficiency, performance, and reliability of the system. Understanding its role and the engineering principles behind it allows automotive enthusiasts and engineers alike to appreciate the intricacies of turbocharging technology. As the demand for higher performance continues to rise, innovations in turbocharger housing design and materials are likely to shape the future of automotive engineering, pushing the boundaries of what is possible in engine performance and efficiency.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025