Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding Pipe Cap Fittings and Their Applications in Plumbing Systems

Understanding Pipe Cap Fittings A Comprehensive Overview

Pipe cap fittings are essential components in a variety of industrial and domestic applications. These fittings serve a critical role in managing the flow of liquids and gases through piping systems, ensuring that they operate efficiently and effectively. In this article, we will explore the purpose, types, materials, and installation of pipe cap fittings, providing you with a comprehensive understanding of this important plumbing component.

What Are Pipe Cap Fittings?

Pipe cap fittings are used to seal the end of a pipe to prevent the passage of fluids, gases, or other substances. They essentially close off the piping system at the end of a line, ensuring that there is no leakage or contamination. This is crucial in many industries, including oil and gas, water treatment, and chemical processing, where the integrity of the piping system is vital.

Types of Pipe Cap Fittings

There are several types of pipe cap fittings available, each designed for specific applications. The most common types include

1. End Caps These are the simplest form of pipe caps. They are designed to seal the end of a pipe completely, providing a tight closure. End caps are used in various applications, from plumbing to industrial piping systems.

2. Threaded Caps These caps have internal threads that allow them to screwing onto the end of a threaded pipe. They are commonly used in applications where a secure closure is necessary, and they can be easily removed for maintenance or inspection.

3. Welded Caps Welded caps are permanently attached to the pipe by welding. This type of fitting is ideal for high-pressure applications where a leak-proof seal is essential. They are used extensively in the oil and gas industry.

4. Socket Caps This type of cap fits over the end of the pipe and is usually glued using solvent cement. Socket caps are lightweight and easy to install, making them a popular choice for PVC and CPVC piping systems.

Materials Used in Pipe Cap Fittings

Pipe cap fittings are available in a range of materials, allowing for their use in various environments. Common materials include

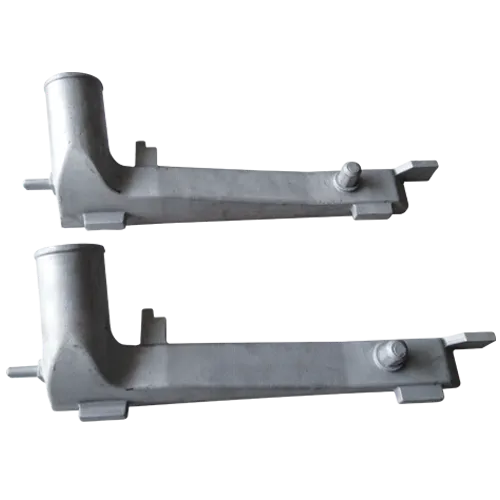

pipe cap fitting

- PVC (Polyvinyl Chloride) PVC caps are lightweight, resistant to corrosion, and suitable for various chemical applications. They are commonly used in residential plumbing as well as irrigation systems.

- CPVC (Chlorinated Polyvinyl Chloride) CPVC caps can handle higher temperatures compared to standard PVC and are often used in hot water systems.

- Metal (Steel, Stainless Steel, Brass) Metal caps are used in more demanding applications. Stainless steel caps, for instance, provide excellent corrosion resistance and are often found in the food processing and pharmaceutical industries.

Installation of Pipe Cap Fittings

Installing pipe cap fittings is a straightforward process, but it requires attention to detail to ensure a proper seal. The installation steps typically include

1. Preparation Clean the end of the pipe to remove any debris, rust, or old sealant. This step is crucial for creating a tight seal.

2. Fitting the Cap Depending on the type of cap, either screw it onto the threaded pipe, push it into place for a socket cap, or position it for welding.

3. Sealing For threaded caps, use Teflon tape to ensure a watertight seal. For glued connections, apply solvent cement evenly, following the manufacturer's instructions.

4. Testing Once installed, it's essential to test for leaks by pressurizing the system or checking for water ingress after filling the connected system.

Conclusion

Pipe cap fittings play a vital role in the functionality and safety of piping systems. Understanding their types, materials, and installation processes can help you choose the right fittings for your specific needs. Whether you are a professional plumber or a DIY enthusiast, familiarizing yourself with these essential components ensures your projects run smoothly and efficiently.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025