Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding Impeller Wear and Its Impact on Pump Performance and Efficiency

Impeller Wearing Causes, Effects, and Mitigation Strategies

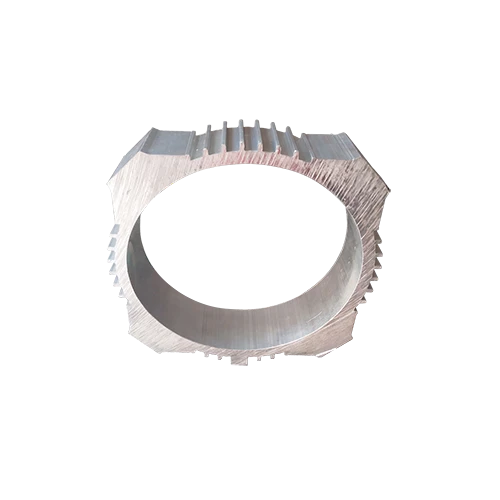

Impellers are a critical component in various industrial applications, particularly in pumps and turbines, playing a vital role in fluid dynamics. However, impeller wear is a common issue that can significantly affect efficiency and operational lifespan. Understanding the causes, effects, and mitigation strategies for impeller wearing is essential for industries relying on these mechanisms for optimal performance.

Causes of Impeller Wearing

Impeller wear typically results from a combination of mechanical and environmental factors. One primary cause is the erosion from abrasive particles within the fluid being pumped or circulated. In industries such as mining or wastewater treatment, the presence of solid particles can lead to significant wear on the impeller surfaces. Additionally, cavitation, a phenomenon where vapor bubbles form in low-pressure areas and subsequently collapse, generates shock waves that can erode materials.

Another significant factor leading to impeller wear is corrosion, which can be accelerated by the chemical composition of the fluid. In environments where fluids are corrosive, such as in chemical processing, the choice of materials for impeller construction becomes crucial. If the material is not resistant to the specific chemicals it encounters, wear will occur more rapidly.

Operational conditions also contribute to impeller wear. For instance, running an impeller beyond its design specifications—in terms of flow rate, speed, or temperature—can exacerbate wear. Furthermore, improper alignment and installation can lead to increased friction and uneven wear patterns.

Effects of Impeller Wearing

The consequences of impeller wear can be profound, affecting both efficiency and safety. As wear progresses, the performance of the impeller diminishes, leading to reduced pumping capacity and increased power consumption. This inefficiency not only raises operational costs but can also lead to equipment failure if not addressed promptly.

impeller wearing

In severe cases, significant wear can result in catastrophic failures, leading to unplanned downtime, costly repairs, and potential safety hazards for personnel. Additionally, measuring the effectiveness of a pumping system becomes challenging with a worn impeller, as it may not provide accurate readings of flow rates or pressure.

Moreover, the environmental impact should not be overlooked. Inefficient pumps may lead to higher energy consumption, contributing to a larger carbon footprint and increased operational costs for companies.

Mitigation Strategies

To combat impeller wearing, several strategies can be implemented. Firstly, selecting the right material for impeller construction is crucial. Using hard, corrosion-resistant materials such as stainless steel, titanium, or advanced composites can help extend the lifespan of the impeller, particularly in harsh environments.

Regular maintenance and inspections are also essential. By monitoring wear patterns and identifying issues before they escalate, companies can schedule timely repairs or replacements. Implementing smart monitoring technologies that provide real-time data on impeller performance can significantly improve maintenance practices.

Additionally, operating within the specified parameters is critical. Ensuring that the pump runs at its optimal performance levels helps minimize wear. Training personnel on the importance of following operational guidelines can further prevent unnecessary wear.

Finally, employing protective measures such as wear-resistant coatings or liners can provide a barrier between the impeller and the abrasive or corrosive elements in the fluid. This proactive approach can significantly extend the life of the impeller.

In conclusion, while impeller wear is an inevitable challenge in various industrial applications, understanding its causes and effects allows for the implementation of effective mitigation strategies. By prioritizing material selection, maintenance, operational guidelines, and protective measures, industries can enhance the performance and longevity of their impellers, ultimately driving efficiency and reducing costs.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025