Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Two-Stage Impeller Design for Enhanced Fluid Dynamics Efficiency

The Efficiency and Design of 2-Stage Impellers

In the realm of fluid dynamics and mechanical engineering, impellers play a crucial role in the development of pumps, turbomachines, and various other devices that facilitate the movement of fluid. One notable type of impeller is the 2-stage impeller, which offers enhanced efficiency and performance in certain applications. In this article, we will explore the design, advantages, and applications of 2-stage impellers.

Understanding the Structure of 2-Stage Impellers

A 2-stage impeller consists of two sets of blades that operate sequentially to achieve the desired pressure and flow characteristics. The primary function of the impeller is to convert mechanical energy from the prime mover (like an electric motor or turbine) into kinetic energy in the fluid, which then translates into increased pressure and flow. The two stages allow for a greater increase in pressure and improved flow rates compared to single-stage designs.

In a typical 2-stage impeller arrangement, the fluid enters the first stage, where it is accelerated by the blades, resulting in a significant increase in velocity. As the fluid exits the first impeller stage, it enters a diffuser or a second impeller stage, which further enhances the pressure and transforms some of the kinetic energy back into pressure energy. This sequential processing is critical for applications that require high-pressure output while maintaining an efficient hydraulic design.

Advantages of 2-Stage Impellers

1. Increased Efficiency One of the primary benefits of 2-stage impellers is their ability to achieve higher efficiency levels compared to single-stage impellers. The flow transitions over the two stages allow for better energy utilization, leading to reduced energy costs in pumping operations.

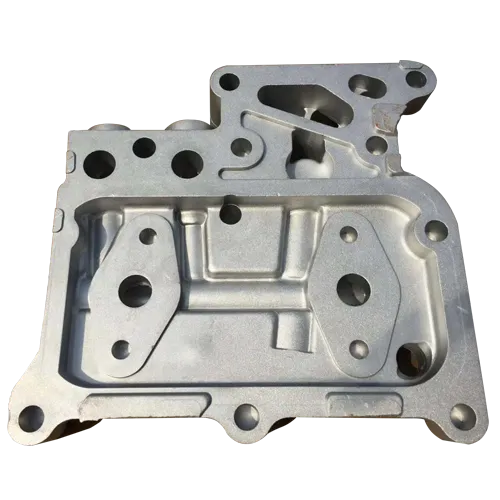

2 stage impeller

2. Improved Pressure Output The ability to generate higher pressure output makes 2-stage impellers ideal for applications in which the fluid needs to be transported over long distances or against significant pressure drops, such as in municipal water supply systems or industrial processes.

3. Space Savings By combining two stages into one impeller assembly, manufacturers can design compact systems that save valuable space in various applications, particularly in industries where space is at a premium.

4. Versatility 2-stage impellers can be designed for various operational conditions, including different flow rates and pressure conditions. This adaptability makes them suitable for a wide range of industries, from HVAC systems to agriculture and chemical processing.

Applications of 2-Stage Impellers

The versatility of 2-stage impellers allows them to be utilized in numerous applications. In the water supply sector, they are commonly found in booster pumps that elevate water from lower elevations to higher storage tanks. In the oil and gas industry, 2-stage impellers are used in various pumps for transporting crude oil and refined products under high pressure. Additionally, in renewable energy, these impellers can be integrated into wind and hydroelectric power generation systems to optimize fluid movement and efficiency.

Conclusion

The design and functionality of 2-stage impellers signify a critical advancement in fluid machinery technology. Their ability to combine multiple stages within a single unit enhances both efficiency and performance, making them indispensable in various industrial applications. As technology continues to evolve, the design and application of 2-stage impellers will likely develop further, improving their efficiency and expanding their use in new and innovative ways. With ongoing research and development, the future of impeller technology looks promising, and 2-stage designs will undoubtedly play a vital role in shaping it.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025