Mobile:+86-311-808-126-83

Email:info@ydcastings.com

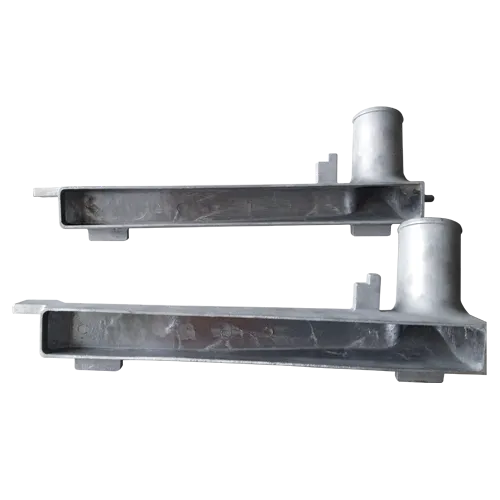

turbine pump impeller

Understanding Turbine Pump Impellers Their Design, Function, and Applications

Turbine pumps are essential components in various industries, ranging from water treatment to oil and gas, due to their ability to efficiently move fluids. At the heart of these pumps lies the impeller, a critical element that plays a vital role in the pump's performance and efficiency. This article explores the design, function, and applications of turbine pump impellers.

The Role of Impellers in Turbine Pumps

The impeller in a turbine pump is designed to convert mechanical energy into kinetic energy, which then transforms into pressure energy in the fluid being pumped. The functionality of the impeller is fundamentally characterized by its geometric design, which includes the number of blades, blade shape, and diameter. Each of these features directly influences how efficiently the pump can move fluid.

When a turbine pump operates, the impeller rotates, creating a centrifugal force that draws fluid into the pump. The fluid enters the impeller along its axis and is drawn outward through the blades, gaining velocity. This acceleration contributes to an increase in pressure as the fluid exits the impeller and moves into the diffusion stage of the pump, where the flow is converted into a steady flow with higher pressure.

Design Characteristics of Impellers

The design characteristics of turbine pump impellers are crucial for maximizing efficiency and performance

. Commonly, impellers can be classified into two main types open and closed.1. Open Impellers These consist of blades that are not enclosed by a shroud. Open impellers are easier to clean and maintain, making them suitable for handling fluids with a high concentration of solids or slurries. However, they may be less efficient than closed impellers under certain conditions.

2. Closed Impellers These have blades enclosed between two shrouds, providing better control over the flow and improving overall efficiency. Closed impellers are ideal for applications requiring high flow rates and consistent performance over varying operational conditions.

turbine pump impeller

Additionally, the number of blades can affect the pump's efficiency. More blades typically provide better flow, but may also create higher resistance to flow. Therefore, an optimal balance must be struck to achieve the desired performance characteristics.

Material Choices for Impellers

The materials used to fabricate turbine pump impellers must be selected carefully, considering the intended application and the type of fluid being pumped. Common materials include stainless steel, bronze, and various polymers. Stainless steel is often used for its corrosion resistance, especially in applications involving harsh chemicals or seawater. Bronze impellers are favored for their strength and resistance to cavitation, while polymers may be chosen for their lightweight and economical properties in less demanding scenarios.

Applications of Turbine Pump Impellers

Turbine pump impellers are utilized in a wide array of applications. In the water treatment industry, they help transport water through filtration and treatment systems. In the oil and gas sector, they assist in moving hydrocarbons from wellheads to processing facilities. Additionally, turbine pumps are prevalent in irrigation systems, fire protection systems, and chemical processing applications.

As industries continue to evolve, the demand for more efficient and reliable turbine pump solutions remains high. Innovations in impeller design, such as improvements in aerodynamic efficiency and materials science, will likely drive the next generation of turbine pump technology.

Conclusion

In conclusion, turbine pump impellers are integral to the effective and efficient movement of fluids across various industries. Their design, material composition, and operational characteristics significantly impact pump performance. As technology progresses, advancements in impeller design will continue to enhance the capabilities of turbine pumps, ensuring they meet the ever-growing demands of modern applications. Through continuous innovation, turbine pump impellers will play a pivotal role in supporting various industrial processes, driving efficiency and reliability in fluid transport systems worldwide.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025