Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing T25 Turbine Housing for Enhanced Performance and Efficiency in Modern Applications

The Evolution and Significance of the T25% Turbine Housing

The T25% turbine housing has emerged as a critical component in modern engineering, particularly within the fields of automotive and aerospace industries. As the demand for high-performance engines intensifies and sustainability becomes a key focus, the design and functionality of turbine housings have evolved significantly.

Understanding the T25% Turbine Housing

To comprehend the importance of the T25% turbine housing, one must first understand its role in turbocharged engines. Turbochargers work by expelling exhaust gases to spin a turbine, which in turn draws in more air and improves engine efficiency and power output. The T25% measurement refers to the inlet and outlet dimensions that facilitate the optimized flow of air and exhaust. This specific sizing allows for a balance between responsiveness and performance, making it a preferred choice among enthusiasts and engineers alike.

Design Innovations

Over the years, advancements in materials and engineering techniques have led to the development of more efficient turbine housings. The use of lightweight, heat-resistant materials helps reduce overall vehicle weight while improving thermal efficiency. Modern T25% turbine housings often feature enhanced aerodynamics, allowing for smoother airflow and reduced turbulence, which translates to better performance.

In addition, the integration of 3D printing technology has revolutionized the design and manufacturing process of turbine housings. Engineers can now create intricate geometries that were previously impossible to achieve, resulting in more compact and efficient designs. This technological leap not only enhances performance but also reduces production costs and time.

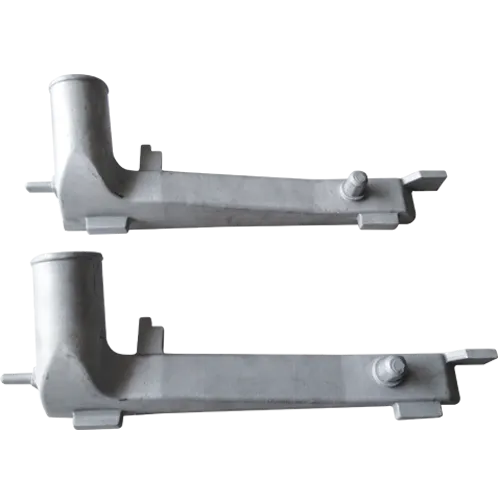

t25 turbine housing

Performance Benefits

The benefits of using a T25% turbine housing are manifold. The optimized size and shape contribute to quicker spool times, meaning the turbocharger can reach its performance threshold faster. This is particularly advantageous in applications where responsiveness is crucial, such as in motorsports or high-performance road vehicles.

Moreover, enhanced thermal management within the turbine housing leads to lower exhaust gas temperatures, allowing the engine to run more efficiently without the risk of overheating. As a result, cars equipped with the T25% turbine housing can achieve better fuel economy and lower emissions, aligning with the global shift towards greener technologies.

Applications Across Industries

The versatility of the T25% turbine housing extends beyond automotive uses. Its principles are applicable in aviation, marine, and even power generation sectors. In aviation, for instance, efficient turbine housings can significantly improve the power-to-weight ratio of engines, leading to better aircraft performance. Similarly, in marine applications, using optimized turbine housings can enhance fuel efficiency and reduce operational costs.

Conclusion

The T25% turbine housing represents a pivotal advancement in turbocharger technology that plays a vital role in enhancing engine performance, efficiency, and reliability. Its significance is underscored by the ongoing innovation in its design and manufacturing processes, heralding a future where such components become even more integral to achieving high performance in various applications. As industries push towards greater environmental sustainability and efficiency, the T25% turbine housing stands at the forefront of this evolution, enabling a new generation of powerful, efficient, and eco-friendly engines.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025