Mobile:+86-311-808-126-83

Email:info@ydcastings.com

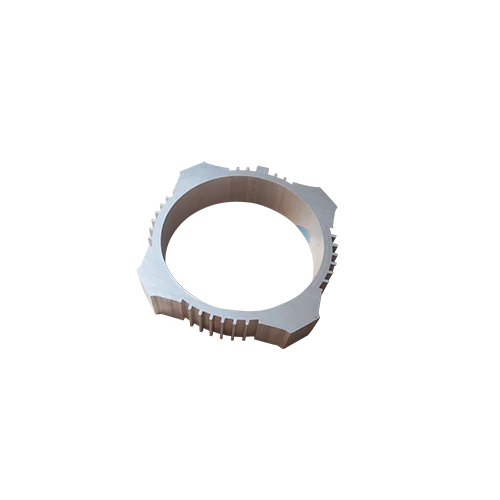

Design and Functionality of Submersible Pump Casings for Optimal Performance and Durability

Submersible Pump Casing An Essential Component in Fluid Management

Submersible pumps are widely used in various industries for their efficiency in moving fluids from one place to another. Whether it's for irrigation, drainage, or even sewage management, these pumps need to operate effectively and reliably. At the heart of every submersible pump lies its casing, a crucial component that not only encases the pump but also plays a vital role in its overall performance.

The casing of a submersible pump serves multiple functions. First and foremost, it protects the internal components of the pump, such as the motor and impeller, from the harsh environmental conditions encountered in water or other fluid bodies. This protection is particularly important in environments that may contain abrasives, chemicals, or varying temperatures, which could otherwise lead to premature wear and breakdown.

Moreover, the design of the pump casing significantly impacts its efficiency. A well-designed casing minimizes hydraulic losses and optimizes the flow of fluid through the pump. This efficiency is crucial for reducing energy consumption and operational costs, as poorly designed casings can lead to turbulence and back pressure, reducing the pump's overall performance.

submersible pump casing

Material selection is another critical aspect of submersible pump casings. They are commonly made from stainless steel, cast iron, or even high-grade polymers, depending on the application and fluid type. Stainless steel, for example, is favored for its corrosion resistance and durability, making it suitable for applications involving aggressive chemicals. Conversely, cast iron may be used for its strength in heavier-duty applications.

In addition to protecting components and enhancing efficiency, the casing also plays a role in cooling the pump motor. Submersible pumps rely on the surrounding fluid for cooling, and the casing helps facilitate the flow of this fluid around the motor, thereby maintaining optimal operating temperatures and preventing overheating.

Regular maintenance and inspections of the pump casing are essential to ensure its longevity and optimum performance. Over time, wear and tear can occur due to abrasive particles in the fluid or chemical corrosion. Monitoring the condition of the casing can prevent unexpected failures and prolong the life of the pump.

In summary, the submersible pump casing is a vital component in the fluid management system, providing protection, enhancing efficiency, and contributing to the overall functionality of the pump. Understanding the importance of this component can help users select the right pump for their specific needs and ensure effective operation in demanding environments.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025