Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Stainless Steel Casting Pricing Factors and Market Trends Analysis

The Price of Stainless Steel Casting Factors and Trends

Stainless steel casting is an essential manufacturing process used in various industries, including automotive, aerospace, construction, and food processing. Its unique properties, such as resistance to corrosion, high strength, and aesthetic appeal, make stainless steel an ideal choice for many applications. However, one of the primary considerations for businesses looking to utilize stainless steel casting is the associated cost. This article explores the factors that influence the price of stainless steel casting and the current trends in the market.

Factors Influencing Stainless Steel Casting Prices

1. Material Composition The price of stainless steel casting is heavily affected by the specific grade of stainless steel used. There are various grades, such as 304, 316, and 410, each with different properties and costs. For instance, 316 stainless steel, which contains molybdenum for enhanced corrosion resistance, is typically more expensive than 304 stainless steel. The choice of material directly influences the casting cost.

2. Market Fluctuations The price of raw materials, particularly nickel and chromium, plays a significant role in determining the cost of stainless steel. These metals are fundamental components of stainless steel alloys, and their market prices can fluctuate due to various factors, including mining output, trade tariffs, and global demand. As a result, the cost of stainless steel casting can vary over time, reflecting changes in the raw materials market.

3. Manufacturing Process The complexity of the casting process also impacts pricing. Techniques such as investment casting offer high precision and can produce intricate designs but are generally more expensive compared to sand casting. Additionally, factors like mold preparation, labor costs, and production volume play an essential role. High-volume orders tend to reduce the per-unit cost due to economies of scale.

4. Customization and Design Custom-designed stainless steel castings often incur higher costs due to the additional engineering and design work required. When businesses require unique shapes or specifications, this customization necessitates more time and resources, thereby increasing the overall price. Conversely, standard products may come at a lower price point due to established production processes.

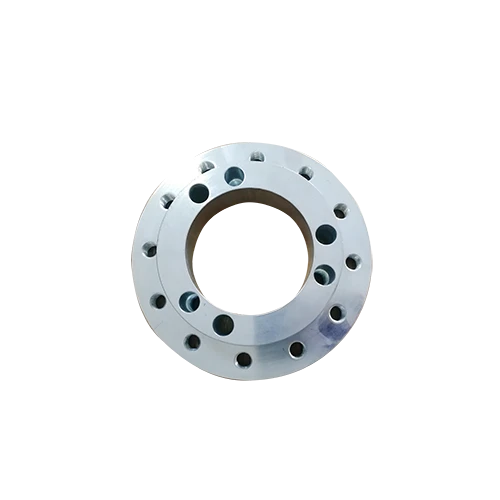

stainless steel casting price

5. Finishing and Treatments After casting, stainless steel parts may undergo various finishing processes, such as machining, polishing, and coating, to enhance their performance and appearance. Each of these processes adds to the production cost. For instance, electropolishing can improve corrosion resistance and aesthetic quality but comes with additional expenses.

Current Market Trends

As of 2023, the stainless steel casting market is experiencing several key trends that influence pricing. The global push for sustainability and eco-friendly manufacturing practices is driving demand for stainless steel due to its recyclability and durability. Consequently, prices may rise as manufacturers invest in greener technologies and processes.

Additionally, the ongoing challenges in global supply chains have created uncertainties that can affect pricing. Disruptions caused by geopolitical events, such as trade disputes or pandemics, can lead to increased costs of raw materials and shipping, thereby influencing the overall pricing structure.

Moreover, companies are increasingly looking for suppliers who can offer versatile and innovative casting solutions, which may command a premium price. Investment in advanced technologies, such as 3D printing for mold creation and automation in production, can also lead to higher initial costs but potentially lower long-term expenditures through increased efficiency.

Conclusion

In summary, the price of stainless steel casting is shaped by a variety of factors, from raw material costs to manufacturing processes and market trends. Businesses interested in stainless steel casting must carefully consider these factors to make informed decisions about their sourcing and budgeting. As the market evolves, staying abreast of these changes will be crucial for maintaining competitiveness and ensuring optimal cost management.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025