Mobile:+86-311-808-126-83

Email:info@ydcastings.com

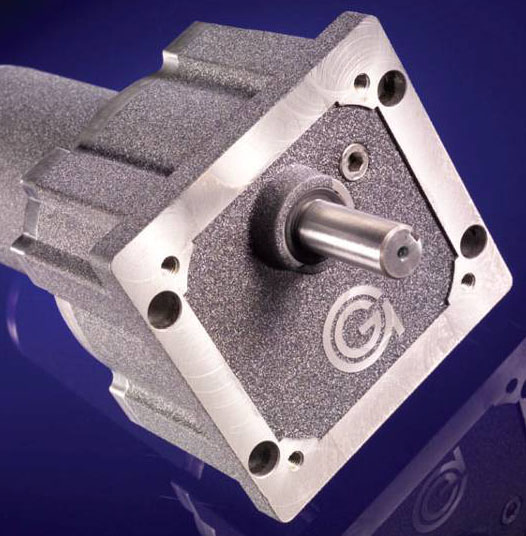

stainless investment casting

Stainless Steel Investment Casting Precision and Versatility in Manufacturing

Stainless steel investment casting is an advanced manufacturing process that plays a crucial role in various industries, thanks to its ability to produce high-precision components with excellent mechanical properties. This method, also known as lost-wax casting, involves creating a wax pattern coated with a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a hollow cavity that is then filled with molten stainless steel.

Stainless Steel Investment Casting Precision and Versatility in Manufacturing

Another significant benefit is the material properties of stainless steel itself. Known for its corrosion resistance, strength, and durability, stainless steel is an ideal choice for parts that must withstand harsh environments and high-stress conditions. Whether it’s a component for a jet engine or a valve used in a chemical processing plant, stainless steel investment casting provides the reliability and longevity required in critical applications.

stainless investment casting

Moreover, stainless steel investment casting is highly versatile. It can accommodate a wide range of stainless steel alloys, allowing manufacturers to select the most suitable material for their specific requirements. This flexibility enables the production of parts with varying mechanical properties, surface finishes, and thermal capabilities, making it a preferred choice for customized solutions in industrial manufacturing.

The investment casting process also offers significant cost benefits. Although it may have a higher initial tooling cost compared to other casting methods, the ability to produce near-net-shape components reduces the need for extensive machining and finishing processes. This results in lower overall production costs, especially for medium to large production runs, and shorter lead times for delivering high-quality parts.

Sustainability is another consideration in modern manufacturing, and stainless steel investment casting fits well within this paradigm. The process generates minimal waste, as the precise nature of casting reduces excess material. Furthermore, stainless steel is recyclable, aligning with the growing demand for environmentally friendly manufacturing practices.

In conclusion, stainless steel investment casting is a vital technique that combines precision, versatility, and sustainability in the production of complex parts across various industries. Its ability to produce high-quality, durable components while minimizing waste makes it a desirable option for manufacturers aiming to meet both performance criteria and environmental standards. As technology continues to evolve, the applications for stainless steel investment casting are likely to expand, paving the way for new innovations and advancements in manufacturing.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025