Mobile:+86-311-808-126-83

Email:info@ydcastings.com

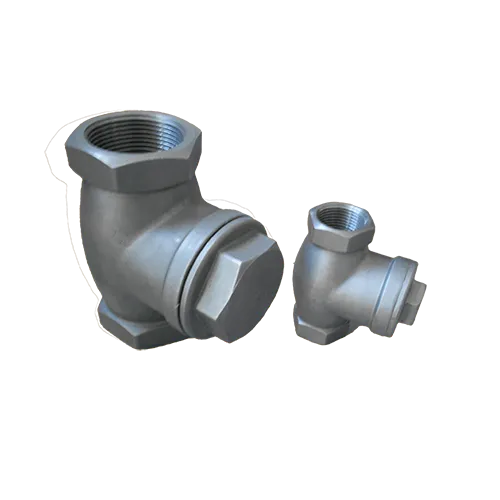

ss pipe cap

Understanding SS Pipe Caps A Comprehensive Overview

Stainless steel (SS) pipe caps are essential components in various piping systems, playing a crucial role in ensuring the integrity and functionality of piping networks. They are typically used to seal the ends of pipes, preventing any unwanted contaminants from entering the system while also maintaining the pressure within.

Understanding SS Pipe Caps A Comprehensive Overview

The design of SS pipe caps is straightforward yet effective. They are usually manufactured in different sizes to accommodate various pipe diameters, ensuring a snug fit that effectively seals the pipe. Furthermore, SS pipe caps come in various types, including tapered, square, and oval caps, allowing for versatility in application. The selection of a specific type depends on the nature of the piping system and the intended use.

ss pipe cap

Installation of SS pipe caps is relatively simple, often requiring welding or threading, depending on the specific requirements of the project. The reliability of SS pipe caps contributes significantly to the overall integrity of a piping system, as leaks can lead to costly repairs and operational downtimes.

In terms of maintenance, SS pipe caps generally require minimal upkeep owing to their corrosion-resistant properties. Regular inspections are advisable to ensure that the caps remain in optimal condition and to identify any signs of wear or damage early on.

In conclusion, SS pipe caps are a vital component of many industrial piping systems, offering durability, reliability, and resistance to corrosion. Their ability to effectively seal pipe ends ensures that the integrity of the overall system is maintained, contributing to efficient and safe operations. Whether in manufacturing, petrochemicals, or water treatment, the importance of stainless steel pipe caps cannot be understated, making them a preferred choice for engineers and maintenance professionals worldwide.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025