Mobile:+86-311-808-126-83

Email:info@ydcastings.com

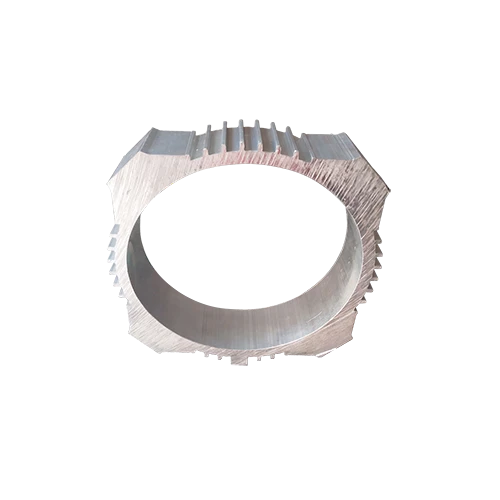

sludge pump impeller

Understanding Sludge Pump Impellers A Comprehensive Overview

In the realm of industrial pumping systems, sludge pumps play a critical role in managing thick, viscous, and often abrasive materials. The efficiency and effectiveness of these pumps heavily depend on their impellers, which are vital components in the conversion of mechanical energy into hydraulic energy. In this article, we will explore the significance of sludge pump impellers, their design features, types, and the important factors to consider when selecting the right impeller for your application.

What is a Sludge Pump and Its Impeller?

A sludge pump is specifically designed to handle the movement of sludges, which can include a variety of materials such as sewage, wastewater, and other viscous mixtures. The impeller in a sludge pump is the rotating part that thrusts the sludge forward through the pump casing, creating a flow.

Importance of Impeller Design

The design of the impeller is crucial in determining the pump’s overall efficiency, performance, and ability to handle different types of sludge. An improperly designed impeller can lead to issues such as clogging, reduced flow rates, and increased wear and tear on the pump components. Therefore, a well-designed impeller contributes to

1. Optimal Performance The right impeller design ensures efficient fluid movement, minimizing energy consumption while maximizing flow rates. 2. Durability Impellers made from high-quality materials reduce wear from abrasive particles in the sludge. 3. Versatility Various designs accommodate different types of sludge, whether it is fibrous, granular, or has high solids content.

Types of Sludge Pump Impellers

Sludge pump impellers can be categorized into several types based on their design and function. The most common types include

1. Open Impellers These impellers have no enclosed casing and usually consist of blades attached to a central hub. Open impellers are excellent for handling liquids with high solids content as they allow for easy passage of larger particles.

2. Closed Impellers Featuring a casement between the blades, closed impellers are more efficient in generating pressure but may struggle with solids. They are best suited for thinner sludges and applications requiring higher pressure.

sludge pump impeller

3. Semi-Open Impellers As a hybrid of open and closed designs, semi-open impellers offer a balance of efficiency and solids handling capabilities, making them versatile for various sludge types.

4. Progressive Cavity Impellers Designed to handle highly viscous fluids, these impellers operate in a helical manner, ensuring a smooth flow of sludge without shearing it into smaller particles.

Key Factors in Selecting an Impeller

When considering which impeller to use for your sludge pump, several factors should be taken into account

1. Sludge Characteristics Analyze the physical and chemical makeup of the sludge, including its viscosity, solids concentration, and presence of fibrous materials. This information will drive the type of impeller suitable for your specific application.

2. Flow Rate and Head Requirements Determine the required flow rate for your system and the total head the pump needs to overcome. Different impeller designs provide varying levels of performance under specific conditions.

3. Material Selection Choose impellers made from materials resistant to corrosion, wear, and tear, especially when dealing with aggressive sludges or highly abrasive materials.

4. Pump Size Ensure that the impeller is properly sized for your pump system to achieve optimal efficiency without causing excessive strain on the pump motor.

Conclusion

Sludge pump impellers are indispensable components that directly impact the efficiency, reliability, and longevity of pumping systems. Understanding the various types of impellers and their characteristics is essential for selecting the right one for your application. By carefully considering the unique properties of the sludge being pumped, along with the required performance metrics, operators can ensure optimal sludge management in various industrial settings. Investing in quality impeller design not only improves operational efficiency but also contributes to the overall sustainability of the pumping system.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025