Mobile:+86-311-808-126-83

Email:info@ydcastings.com

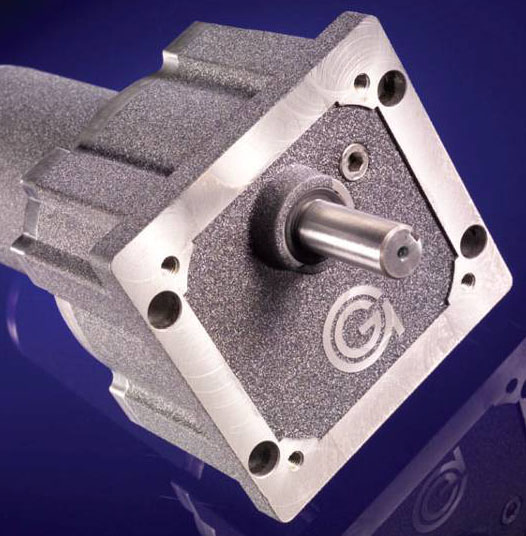

Water pump shell, worm case

The pump impeller is the beating heart of countless industrial and residential applications, playing a critical role in ensuring fluid dynamics work seamlessly and efficiently. As an integral component of centrifugal pumps, the impeller's design and specifications can decisively influence a pump's performance, durability, and energy efficiency.

In industries ranging from water treatment facilities to oil refineries, choosing the right impeller is not a mere afterthought but a calculated endeavor to enhance operational efficiency. A well-designed pump impeller can mitigate common issues such as cavitation—a problem that reduces the pump's lifespan due to the formation of vapor bubbles—and achieve optimal flow rates under varying pressures.

Material selection is of paramount importance when considering an impeller for any specific application. Impeller materials range from cast iron and stainless steel to modern composites like engineering polymers and ceramics, each offering distinct advantages. Stainless steel impellers resist corrosion and are ideal for chemical pumping processes. Conversely, engineering polymers provide lightweight solutions in automotive cooling systems, reducing energy consumption while maintaining efficacy.

Furthermore, the evolution of digital technology offers exciting advancements in the prognostic health management of impellers. IoT sensors embedded in pump systems now allow for constant monitoring of parameters like vibration, temperature, and pressure, providing real-time health diagnoses. This innovation enables predictive maintenance schedules, optimizing maintenance costs and enhancing the trustworthiness of pump systems in critical operations.

Experts in fluid mechanics and machinery espionage stress the importance of collaborating with manufacturers who not only supply impellers but also offer substantial design expertise and testing capabilities. This professional insight ensures each impeller meets the specific requirements of the intended application, from maximum flow capacity to thermal resistance, setting an authoritative standard for performance and safety.

Trust is further established by adhering to industry standards and certifications, such as those from the Hydraulic Institute or the American National Standards Institute (ANSI). These certifications confirm that impellers have been designed, manufactured, and tested in compliance with established quality norms.

Choosing the optimal pump impeller requires a balance of experience-backed decisions, expert guidance, and a commitment to authoritative standards. This balance lays the foundation for a trustworthy system that delivers both performance excellence and operational efficiency.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025