Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 09, 2025 12:05

Back to list

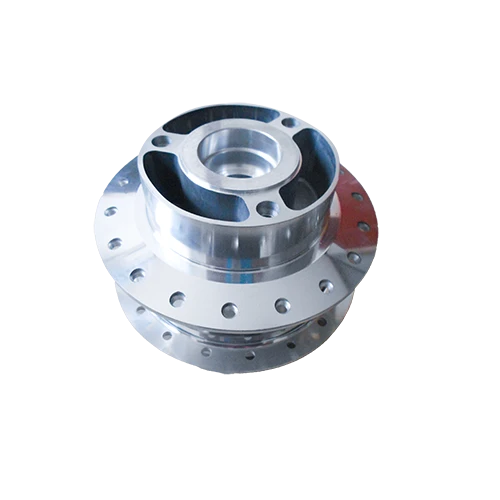

pumpe impeller

Pump impellers are the lifeblood of fluid transport systems, transforming kinetic energy into the flow essential for a myriad of industrial and household applications. Understanding their intricate design and function is crucial for those seeking to optimize pump efficiency and extend the lifespan of these vital components. This article delves into the nuanced aspects of pump impellers, drawing from real-world experiences and expert insights to provide a comprehensive guide on selecting and maintaining these pivotal tools.

Regular maintenance is the cornerstone of impeller longevity and efficiency. Routine inspections for signs of wear and tear, such as pitting or corrosion, can prevent unexpected failures. Balancing the impeller periodically is essential to avoid undue stress on the pump system, which can cause vibrations and operational inefficiencies. Furthermore, adopting predictive maintenance techniques like vibration analysis and thermographic imaging can preemptively identify potential issues before they escalate into costly repairs or downtime. Such proactive strategies, rooted in real-world applications, underscore the value of expertise and foresight in pump management. Integrating digital technology into impeller operations presents a forward-looking approach to pump management. With Industry 4.0, the adoption of smart sensors and IoT connectivity empowers users to monitor impeller performance in real-time, ensuring optimal operation and facilitating swift corrective actions when necessary. For instance, these technologies can provide immediate alerts when deviations from normal operating conditions occur, allowing operators to address issues promptly and maintain system integrity. In conclusion, the impeller's role in a pump system is both foundational and complex. By leveraging expert guidance and experiential knowledge, users can enhance pump performance and efficiency. Whether it's selecting the right impeller design, choosing suitable materials, implementing diligent maintenance practices, or embracing cutting-edge technology, the potential to optimize pump systems is immense. This holistic approach not only safeguards investment but also fortifies trust in the functionality and reliability of pump systems across diverse applications.

Regular maintenance is the cornerstone of impeller longevity and efficiency. Routine inspections for signs of wear and tear, such as pitting or corrosion, can prevent unexpected failures. Balancing the impeller periodically is essential to avoid undue stress on the pump system, which can cause vibrations and operational inefficiencies. Furthermore, adopting predictive maintenance techniques like vibration analysis and thermographic imaging can preemptively identify potential issues before they escalate into costly repairs or downtime. Such proactive strategies, rooted in real-world applications, underscore the value of expertise and foresight in pump management. Integrating digital technology into impeller operations presents a forward-looking approach to pump management. With Industry 4.0, the adoption of smart sensors and IoT connectivity empowers users to monitor impeller performance in real-time, ensuring optimal operation and facilitating swift corrective actions when necessary. For instance, these technologies can provide immediate alerts when deviations from normal operating conditions occur, allowing operators to address issues promptly and maintain system integrity. In conclusion, the impeller's role in a pump system is both foundational and complex. By leveraging expert guidance and experiential knowledge, users can enhance pump performance and efficiency. Whether it's selecting the right impeller design, choosing suitable materials, implementing diligent maintenance practices, or embracing cutting-edge technology, the potential to optimize pump systems is immense. This holistic approach not only safeguards investment but also fortifies trust in the functionality and reliability of pump systems across diverse applications.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS