Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Performance and Efficiency in Pump Application Cases for Better Outcomes

Understanding Pump Cases An Essential Component in Pump Engineering

In the world of mechanical engineering and fluid dynamics, the pump is a pivotal device utilized for transporting liquids and gases. Among the various components that constitute a pump, the pump case plays a crucial role. This article aims to delve into the significance of pump cases, their design, types, material choices, and their impact on pump performance.

What is a Pump Case?

A pump case, often referred to as a pump housing, is the outer shell that encloses the internal components of the pump, including the impeller, mechanical seals, and motor. The primary function of the pump case is to provide a structural framework that maintains the integrity of the pump while ensuring that the fluid is directed efficiently through the system. A properly designed pump case minimizes energy loss, reduces the potential for leaks, and maximizes the flow of the pumped liquid.

Types of Pump Cases

Pump cases come in various types depending on the application and the type of pump being used. The most common types include

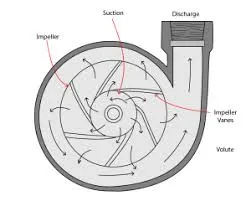

1. Centrifugal Pump Cases Designed to house centrifugal pumps, these cases typically have a volute shape that helps convert the kinetic energy generated by the impeller into pressure. The unique design facilitates smooth fluid flow and minimizes turbulence.

2. Positive Displacement Pump Cases For this type of pump, the case must accommodate mechanisms such as gears, lobes, or diaphragms that create a vacuum to draw in the fluid. The design ensures the pump can deliver a fixed amount of liquid regardless of the pressure downstream.

3. Submersible Pump Cases Found in applications requiring underwater pumping, these cases are built to withstand high pressure and are typically made from corrosion-resistant materials to endure harsh conditions.

Material Considerations

pump case

The choice of materials for pump cases is paramount

. Common materials include- Cast Iron Widely used for its durability and strength, cast iron cases are resistant to wear and can handle high-pressure applications. - Stainless Steel This material is favored in industries such as food processing and pharmaceuticals due to its corrosion resistance and hygienic properties. - Plastics and Composites In more specialized applications, lightweight and chemically resistant materials are employed, particularly when pumping aggressive chemicals.

Design Considerations

The design of a pump case needs to be meticulously planned to achieve optimal performance. Key considerations include

- Flow Path Design The internal geometry must promote a smooth and efficient flow rate while minimizing dead zones where fluid can stagnate. - Pressure Ratings The case must be engineered to withstand pressure fluctuations and extremes specific to the pumping application to prevent failures. - Thermal Management For certain applications, managing heat through the case design is crucial to ensure that the pump operates efficiently and does not overheat.

Impact on Pump Performance

The performance of a pump is inextricably linked to the design and construction of its case. A well-designed pump case can enhance the operational efficiency, reliability, and lifespan of the pump. Conversely, poorly designed cases can lead to issues such as cavitation, mechanical failures, and even unsafe operating conditions.

Conclusion

In conclusion, the pump case is not merely a protective shell; it is a vital component that influences the overall efficiency and effectiveness of a pumping system. With advancements in engineering and materials science, the design of pump cases continues to evolve, ensuring that pumps can meet the demands of increasingly complex industrial applications. Understanding the significance of pump cases enables engineers to make informed decisions that contribute to the development of superior pumping solutions, ultimately enhancing operational efficiency and reliability across various sectors. Whether in agriculture, water treatment, or chemical processing, the critical role of pump cases cannot be understated.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025