Mobile:+86-311-808-126-83

Email:info@ydcastings.com

weld on pipe caps

Single and double volute casing

Pump Casing

The casing is the major stationary component of the pump and mainly provides two functions:

- Converting velocity head from the impeller into pressure head and guidance of the flow to the discharge connection

- Creating a pressure boundary for the pumped liquid

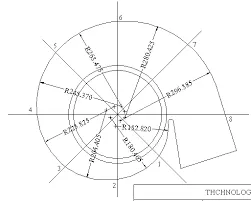

A pump casing is often referred to as a volute. A volute is a spiral-like geometry with an increasing through-flow area, reducing the velocity of the fluid and increasing the static pressure. The fluid exiting the impeller is then diffused towards the casing discharge nozzle. These volute casings come in two different types: single volute and double volute.

Single Volute Casing

In a single volute casing, the impeller discharges into one volute that wraps completely around the impeller. This type of casing features one cutwater that directs the flow of the liquid towards the discharge of the pump.

Volute Case

Double Volute Casing

Double volute casings have two cutwaters located 180 degrees apart from each other. Normally a double volute pump can be identified simply by looking down the discharge flange: a noticeable vane is located inside the nozzle that divides the inner diameter of the discharge nozzle.

The main advantage of a double volute over a single volute is the balancing of radial loads on the impeller, as the double cutwater construction leads to a more equal pressure distribution in the volute. Minimizing the radial load on the bearings over the full operating range can have a significant impact on the lifetime of a pump, since bearing failures are the second most common reason for pump failures. However, a double volute adds additional hydraulic resistance.

In addition to single and double volute casings, another type of pump casing exists: the diffuser casing.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025