Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High-Precision Metal Casting Techniques for Superior Industrial Applications and Performance

Precision Metal Casting An Overview

Precision metal casting is a sophisticated manufacturing process that plays a crucial role in a variety of industries, including aerospace, automotive, medical, and electronics. This technology involves creating complex metal parts with high-dimensional accuracy and excellent surface finishes. With the rapid advancement of materials science and engineering, precision metal casting continues to evolve, becoming an integral part of modern manufacturing.

At its core, the precision metal casting process involves several key steps pattern making, mold creation, melting, pouring, and finishing. The first step is to create a pattern, usually made from materials like metal or plastic, which replicates the exact shape and dimensions of the final product. This pattern is then used to produce a mold, often using sand or other materials that can withstand the pouring of molten metal.

Once the mold is prepared, the chosen metal—often steel, aluminum, or other alloys—is melted to a specific temperature. The molten metal is then carefully poured into the mold. The casting process requires precise control of temperature and pouring techniques to prevent defects like air bubbles or inclusions, which can compromise the integrity of the final product. After allowing sufficient time for cooling and solidification, the mold is removed, revealing the cast part.

Precision is one of the primary advantages of this casting technique. Unlike traditional metal forming methods, which can be limited in terms of complexity and precision, precision casting allows for intricate designs with tight tolerances. This is particularly beneficial in industries like aerospace, where component weight and performance are critical. Components such as turbine blades, housings, and frames can be manufactured with remarkable accuracy, reducing the need for extensive machining and further processing.

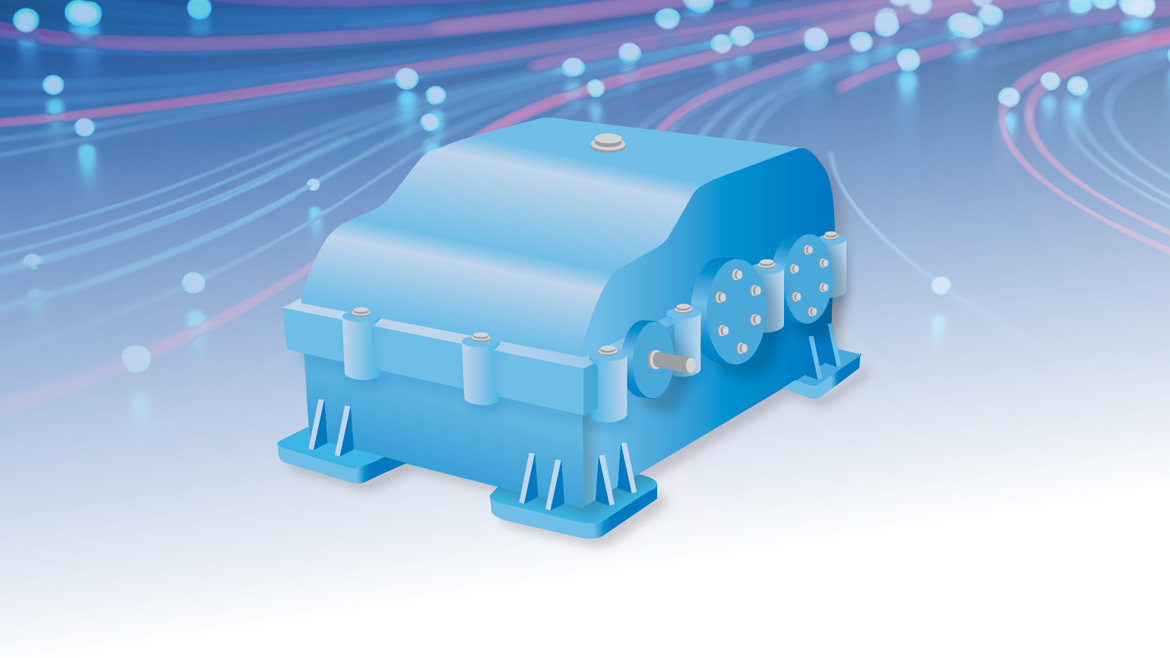

precision metal casting

Moreover, precision metal casting offers several material options, enabling manufacturers to select the best metals for their specific applications. High-strength alloys can be used for parts that need to withstand extreme conditions, while lighter metals may be chosen for components requiring weight reduction. This versatility enhances the ability to innovate and create customized solutions tailored to meet the demands of various applications.

Another significant benefit of precision metal casting is its cost-efficiency for large production runs. While the initial setup, including pattern making and mold creation, can be expensive, the overall cost per unit decreases as production volumes increase. This makes precision metal casting an attractive option for manufacturing large quantities of similar parts, providing significant savings over time.

Environmental considerations also play a role in the growing popularity of precision metal casting. Modern casting processes have adopted more sustainable practices, with many manufacturers focusing on recycling metal scrap and using eco-friendly materials. Innovations such as 3D printing are being integrated into the casting process, further reducing waste and improving efficiency.

Looking ahead, the future of precision metal casting appears promising. With ongoing advancements in technology, including improvements in CAD (computer-aided design) and simulation software, manufacturers can predict and rectify issues before production begins. This proactive approach not only enhances quality but also reduces turnaround times.

In conclusion, precision metal casting is a vital process in contemporary manufacturing, providing high-quality, intricate components across various industries. Its ability to produce complex geometries with tight tolerances, combined with material versatility and cost-effectiveness, positions it as a cornerstone of modern engineering. As technology continues to advance, the impact of precision metal casting on manufacturing excellence will undoubtedly grow, paving the way for innovation and efficiency in multiple sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025