Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Precision Stainless Steel Casting | Durable Metal Components

Advancing Industrial Solutions with Stainless Steel Casting

The landscape of industrial manufacturing is continuously evolving, with a persistent demand for components that offer superior strength, durability, and corrosion resistance. In this high-stakes environment, stainless steel casting emerges as a pivotal technology, delivering unparalleled performance for critical applications. This specialized metal forming process enables the production of intricate parts capable of withstanding extreme conditions, from high temperatures and pressures to corrosive chemical environments. Its inherent properties make it indispensable across a multitude of sectors, driving innovation and reliability in essential infrastructure and machinery.

Recent industry trends highlight a significant uptick in the adoption of advanced casting techniques. The global market for metal castings, including both ferrous and non-ferrous alloys, is projected to grow steadily, driven by increased investments in infrastructure development, energy production, and the automotive sector. While `aluminum die casting` and `green sand metal casting` remain popular for specific applications due to their cost-effectiveness and rapid production cycles, the demand for `stainless steel casting` is experiencing robust growth, particularly for high-performance components where integrity and longevity are paramount. This trend is fueled by the need for enhanced material performance, tighter tolerances, and greater design flexibility, which traditional manufacturing methods often struggle to meet. The shift towards sustainable manufacturing practices also favors processes that produce durable, long-lasting components, reducing the need for frequent replacements and minimizing waste.

The Precision Manufacturing Process of Stainless Steel Casting

The creation of high-quality `metal castings`, particularly those from stainless steel, involves a meticulously controlled, multi-stage process designed to achieve specific metallurgical and dimensional characteristics. Unlike `aluminium metal casting` or `aluminum casting die` processes which often prioritize speed and lightweight properties, `stainless steel casting` focuses on achieving superior strength, corrosion resistance, and precision for demanding industrial applications. The typical process flow can be broken down into several critical steps:

1. Pattern Making

Creation of a replica of the desired part, typically from wax or other expendable materials. Critical for defining the final component's geometry and surface finish.

2. Molding & Shell Building

For investment casting, the wax pattern is repeatedly dipped into ceramic slurry and coated with refractory sand to build a strong ceramic shell. For sand casting, patterns are packed with sand.

3. Dewaxing/Mold Drying

The ceramic mold is heated to melt and remove the wax pattern, leaving a hollow cavity. Sand molds are dried and cored if necessary.

4. Melting & Pouring

High-grade stainless steel alloys (e.g., 304, 316, 17-4PH) are melted in induction furnaces, often under vacuum or inert atmosphere to prevent contamination. Molten metal is then poured into the preheated ceramic molds.

5. Solidification & Shakeout

The metal cools and solidifies within the mold. Once cooled, the ceramic shell is broken away (shakeout) to reveal the rough casting.

6. Finishing & Heat Treatment

Gates and risers are removed, and the casting is ground smooth. Heat treatments (e.g., annealing, solution treatment, precipitation hardening) are applied to optimize mechanical properties and stress relief.

7. Machining & Inspection

CNC machining for tight tolerances, followed by rigorous testing: NDT (X-ray, ultrasonic, MPI, LPI), dimensional inspection, mechanical testing, and chemical analysis. Products adhere to standards like ISO 9001, ASTM A743/A744, and ANSI.

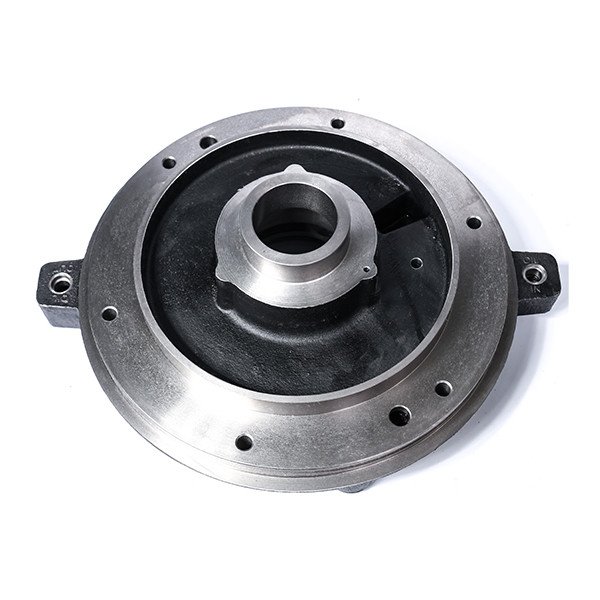

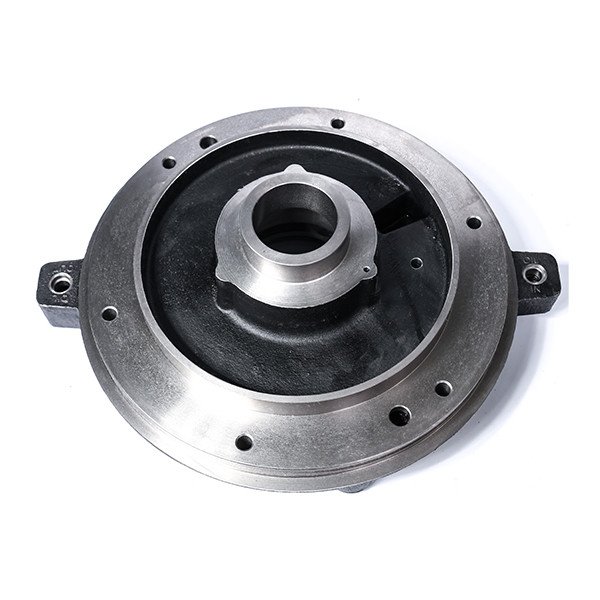

The service life of components manufactured through this process, such as Cooling Flange Lowers and Bearing Housing Lowers, can extend decades, particularly in challenging environments like petrochemical plants or water supply & drainage systems, owing to their superior corrosion resistance and mechanical integrity. This longevity translates directly into significant energy saving and reduced maintenance costs over the lifecycle of the equipment.

Technical Specifications and Performance Parameters

Understanding the technical specifications of `stainless steel casting` is crucial for engineers and procurement professionals to ensure optimal performance in their applications. The choice of specific stainless steel grade significantly impacts mechanical properties, corrosion resistance, and suitability for various operating conditions. Here, we outline key parameters relevant to high-performance industrial components like Cooling Flanges and Bearing Housings.

Typical Stainless Steel Casting Grades and Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Key Characteristics |

|---|---|---|---|---|---|

| ASTM A743 Grade CF8 (304) | ≥ 485 | ≥ 205 | ≥ 35 | ≤ 190 | General corrosion resistance, good weldability, common in food/chemical. |

| ASTM A743 Grade CF8M (316) | ≥ 485 | ≥ 205 | ≥ 30 | ≤ 190 | Superior corrosion resistance, especially against chlorides, marine, pulp & paper. |

| ASTM A747 Grade CB7Cu-1 (17-4PH) | ≥ 930 | ≥ 725 | ≥ 8 | ≥ 290 | High strength and hardness, good corrosion resistance, aerospace, defense. |

Product Specification: Cooling Flange Lower & Bearing Housing Lower

These components, integral to various rotating machinery and fluid handling systems, demand exceptional material integrity and precise dimensions. For instance, a Cooling Flange Lower requires excellent thermal stability and corrosion resistance to manage temperature differentials effectively, while a Bearing Housing Lower needs robust mechanical strength and dimensional accuracy to ensure smooth operation and extended bearing life.

| Parameter | Cooling Flange Lower (Example) | Bearing Housing Lower (Example) |

|---|---|---|

| Material Grade | ASTM A743 Grade CF8M (316) | ASTM A743 Grade CF8 (304) |

| Weight Range | 0.5 kg - 50 kg | 1 kg - 100 kg |

| Dimensional Tolerance | ISO 8062 CT7-CT9 (as-cast) | ISO 8062 CT7-CT8 (as-cast) |

| Surface Finish | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) |

| Testing Standards | ISO 9001, ASTM E8 (Tensile), ASTM A370 (Hardness) | ISO 9001, ASTM E8 (Tensile), ASTM A370 (Hardness) |

| Heat Treatment | Solution Annealing | Solution Annealing |

Technical Advantages and Key Application Scenarios

The inherent properties of `stainless steel casting` offer a myriad of technical advantages, making it the material of choice for demanding industrial applications. These benefits translate directly into enhanced operational efficiency, reduced maintenance, and extended service life for critical components.

- Exceptional Corrosion Resistance: Stainless steels form a passive chromium oxide layer, providing superior resistance to oxidation, acids, alkalis, and chlorides. This is vital in environments like chemical processing, marine, and offshore oil and gas, where component integrity is constantly challenged by aggressive media. This characteristic far surpasses the resistance offered by many other `metal castings`.

- High Temperature Strength and Creep Resistance: Many stainless steel grades maintain their mechanical properties at elevated temperatures, making them suitable for furnace components, exhaust systems, and high-temperature fluid handling. This ensures structural integrity and dimensional stability under thermal stress.

- Superior Strength-to-Weight Ratio: Especially with duplex or precipitation-hardening grades, stainless steel offers high strength with relatively lower weight compared to some other alloys, contributing to more efficient designs and reduced static loads.

- Design Flexibility: The casting process allows for the production of complex geometries and intricate internal passages that would be difficult or impossible to achieve with forging or machining alone. This enables optimized designs for fluid dynamics, heat exchange, and component integration.

- Durability and Longevity: The combination of corrosion resistance, mechanical strength, and fatigue resistance results in components with extended service lives. This reduces downtime for repairs and replacements, leading to significant energy saving and lower lifecycle costs.

Target Industries and Application Examples:

- Petrochemical & Oil & Gas: Valve bodies, pump casings, impellers, Cooling Flange Lowers, and Bearing Housing Lowers used in refineries, offshore platforms, and chemical processing plants, where exposure to corrosive chemicals, high pressures, and extreme temperatures is constant. The corrosion resistance ensures reliable operation and prevents leaks.

- Metallurgy & Mining: Components for smelting furnaces, grinding mills, and material handling equipment that must withstand abrasive wear and high temperatures.

- Water Supply & Drainage: Pump components, fittings, and valve parts in water treatment plants and municipal infrastructure, where resistance to water, mild chemicals, and environmental factors is essential for long-term reliability.

- Marine Industry: Propeller components, pump casings, and other critical parts exposed to saltwater, requiring excellent pitting and crevice corrosion resistance.

- Food & Beverage: Hygienic fittings, valves, and machine parts requiring easy cleaning and resistance to cleaning agents, ensuring product safety and purity.

- Power Generation: Turbine components, heat exchanger parts, and valve systems in conventional and nuclear power plants, where high-temperature strength and corrosion resistance are non-negotiable.

Vendor Comparison and Customized Solutions in Casting

Selecting the right casting partner is as critical as choosing the right material. A competent vendor for `stainless steel casting` offers not just manufacturing capabilities but also engineering expertise, quality assurance, and the flexibility to provide customized solutions. This contrasts significantly with vendors primarily focused on high-volume, less complex processes like `aluminum die casting` or `green sand metal casting`.

Key Factors for Vendor Selection:

- Technical Expertise & Experience: A vendor's depth of knowledge in metallurgy, casting simulation software, and specific industry applications (e.g., petrochemical, marine) is crucial. Years of service and a robust portfolio of similar `metal castings` projects demonstrate experience.

- Quality Certifications: Adherence to international standards like ISO 9001, PED (Pressure Equipment Directive), and AD2000 for critical components. These certifications validate a commitment to consistent quality and process control.

- Manufacturing Capabilities: Assessing the range of casting processes (investment casting, sand casting), melting capacity, machining capabilities (CNC), and heat treatment options. The ability to handle diverse part sizes and complexities is key.

- Testing & Inspection Facilities: In-house NDT (Non-Destructive Testing) capabilities such as X-ray, ultrasonic, magnetic particle, liquid penetrant inspection, and robust CMM (Coordinate Measuring Machine) for dimensional verification.

- Supply Chain Reliability: A vendor's ability to manage raw material sourcing, production scheduling, and logistics to ensure on-time delivery and mitigate supply chain risks.

- Customer Support & Responsiveness: Proactive communication, quick response to inquiries, and dedicated project management.

Customized Solutions: Tailoring to Specific Needs

A superior casting partner goes beyond standard products, offering comprehensive customized solutions. This involves a collaborative approach from initial design to final production:

- Design for Manufacturability (DFM): Expert engineers work with clients to optimize part designs for the casting process, ensuring maximum efficiency, reduced material usage, and enhanced part performance while minimizing costs.

- Material Selection Expertise: Guiding clients in selecting the most appropriate stainless steel grade (e.g., austenitic, martensitic, duplex, precipitation hardening) based on the application's specific requirements for corrosion, temperature, and mechanical loads.

- Prototyping & Rapid Tooling: Offering fast prototyping services to validate designs and material performance before full-scale production.

- Specialized Heat Treatments: Tailoring heat treatment protocols (e.g., solution annealing, quenching and tempering, age hardening) to achieve precise mechanical properties for specialized applications.

- Advanced Finishing & Coating: Providing specialized surface finishes, coatings, or post-processing techniques (e.g., passivation, electropolishing) to further enhance corrosion resistance or reduce friction.

Real-World Application Case Studies

The versatility and robust performance of `stainless steel casting` are best illustrated through real-world applications where these components have delivered critical value. These case studies underscore the benefits of specialized `metal castings` in demanding industrial environments.

Case Study 1: High-Pressure Pump Casing for Chemical Processing

A leading chemical manufacturer faced persistent issues with premature failure of pump casings in a highly corrosive acid transfer system. Previous components, made from less resistant alloys, suffered from rapid pitting corrosion and stress cracking, leading to frequent downtime and high maintenance costs. Our solution involved designing and manufacturing a pump casing using ASTM A743 Grade CF8M (316 stainless steel) through precision investment casting. The complex internal geometries required for optimal fluid flow were achieved with exceptional accuracy. After deployment, the new `stainless steel casting` pump casing demonstrated a service life increase of over 300% compared to its predecessors, significantly reducing operational expenses and improving system reliability. The client reported a substantial energy saving due to reduced leakage and more efficient pump operation.

Case Study 2: Subsea Valve Components for Offshore Oil & Gas

For a critical subsea pipeline project, robust valve components were required to withstand extreme pressures, low temperatures, and aggressive saltwater conditions. Traditional manufacturing methods struggled to produce the intricate internal passages and precise dimensional tolerances necessary for reliable long-term operation at depths exceeding 1,000 meters. We utilized 17-4PH stainless steel `aluminium metal casting` for its superior strength and corrosion resistance. The investment casting process allowed for the creation of highly complex geometries with excellent surface finish, minimizing post-casting machining. Non-destructive testing, including X-ray and ultrasonic inspection, ensured absolute integrity. These components, including specialized Cooling Flange Lowers and Bearing Housing Lowers, have now been in continuous service for over five years without incident, demonstrating the unparalleled reliability of engineered `stainless steel casting` in extreme offshore environments.

Case Study 3: Bearing Housing for Industrial Water Treatment Pumps

An industrial water treatment facility required durable Bearing Housing Lowers for their large-scale centrifugal pumps. These housings were exposed to treated water containing various chemical additives and experienced constant vibration. Cast iron alternatives had issues with rust and premature wear, leading to frequent bearing replacements. We provided custom-designed Bearing Housing Lowers cast from ASTM A743 Grade CF8 (304 stainless steel). The key challenge was achieving tight concentricity and dimensional accuracy for bearing fitment to ensure smooth, vibration-free operation. Through precise CNC machining post-casting and stringent quality control, we delivered components that offered superior resistance to rust and wear. The new stainless steel housings extended bearing life by 50%, significantly reducing maintenance cycles and improving overall pump efficiency, contributing to an overall more sustainable and cost-effective operation for the client.

Commitment to Quality: Standards & Customer Trust

Our dedication to excellence in `stainless steel casting` is deeply rooted in upholding the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (). This commitment is paramount for B2B decision-makers seeking reliable, long-term partnerships.

Expertise & Authoritativeness:

- Certifications: We operate under stringent quality management systems, including ISO 9001:2015, ensuring consistent quality across all processes, from raw material inspection to final product delivery. Our facilities and products often comply with industry-specific standards like PED (Pressure Equipment Directive) and AD2000 for European markets.

- Years of Service: With over two decades of specialized experience in precision `metal castings`, we have developed unparalleled expertise in various alloys, including a wide range of stainless steels, for diverse industrial applications.

- Technical Staff: Our team comprises metallurgical engineers, casting specialists, and CNC programmers, continuously engaged in R&D to optimize casting parameters and material performance.

- Partner Clients: We proudly serve a global clientele, including leading companies in oil & gas, petrochemical, marine, and power generation sectors, who rely on our consistent quality and technical capabilities for their critical components.

Experience & Trustworthiness:

- Customer Feedback: "The precision and material integrity of the `stainless steel casting` components we received exceeded our expectations. Their technical support was invaluable throughout the project." - Senior Engineer, Global Pump Manufacturer.

- Comprehensive Testing: Every batch undergoes rigorous quality checks, including chemical composition analysis, mechanical property tests (tensile, hardness, impact), and non-destructive testing (NDT) such as X-ray and dye penetrant inspection, ensuring compliance with specified standards and customer requirements.

- Traceability: Full material and process traceability is maintained for all castings, from raw material melt number to final inspection reports, providing complete transparency and accountability.

Trust & Transparency: FAQ, Lead Time, Warranty & Support

Building and maintaining trust with our clients is fundamental to our operations. We ensure transparency in our processes, commitments, and support structures.

Frequently Asked Questions (FAQ):

Q: What are the primary advantages of `stainless steel casting` over other methods like forging?

A: Stainless steel casting excels in producing complex geometries and intricate internal features that are difficult or impossible to achieve through forging. It offers superior design flexibility and is often more cost-effective for medium to low volume production of complex parts. While forging offers directional grain flow for ultimate strength, casting allows for tailored metallurgical properties across the part.

Q: What grades of stainless steel do you typically work with?

A: We commonly work with a wide range of austenitic grades (e.g., 304/CF8, 316/CF8M, 304L, 316L), martensitic grades (e.g., 410, CA15), duplex grades (e.g., CD4MCu, 2205), and precipitation-hardening grades (e.g., 17-4PH/CB7Cu-1) to meet various application requirements for strength and corrosion resistance.

Q: Can you handle specialized post-processing requirements like passivation or electropolishing?

A: Yes, we offer comprehensive post-casting services including CNC machining, various heat treatments, surface finishing (e.g., shot blasting, vibratory finishing), and specialized treatments like passivation, electropolishing, and NACE compliance for enhanced corrosion resistance.

Lead Time & Fulfillment:

Our standard lead times are structured to ensure timely delivery without compromising quality. Tooling and prototyping typically take 4-8 weeks depending on complexity. Initial sample production and approval can range from 3-5 weeks. Once samples are approved, mass production lead times usually fall within 4-10 weeks, varying based on order volume, part complexity, and material availability. We employ robust production planning and inventory management systems to meet client schedules efficiently.

Warranty Commitments:

We stand behind the quality of our `metal castings`. All products are manufactured to agreed-upon specifications and international standards. We offer a comprehensive warranty against defects in material and workmanship, typically for 12 months from the date of shipment. Our commitment is to ensure that every component performs as expected in its intended application.

Customer Support & After-Sales Service:

Our dedication extends beyond delivery. We provide continuous technical support, including assistance with material selection, design optimization, and troubleshooting. Our dedicated account managers ensure prompt communication and swift resolution of any inquiries or challenges. We are committed to building long-term partnerships based on mutual trust and sustained performance.

Conclusion and References

In an industrial landscape that increasingly demands reliability, efficiency, and longevity, `stainless steel casting` stands out as a superior manufacturing solution. Its unique combination of corrosion resistance, mechanical strength, and design flexibility positions it as an indispensable process for critical components across diverse sectors. From petrochemical and marine applications to water treatment and general industrial machinery, precision `stainless steel casting` delivers performance that translates into significant operational advantages, extended service life, and a lower total cost of ownership. Partnering with an experienced and technically proficient casting provider ensures access to not only high-quality parts like Cooling Flange Lowers and Bearing Housing Lowers but also to comprehensive engineering support and customized solutions tailored to specific project requirements.

References:

- American Society for Testing and Materials (ASTM). "ASTM A743/A743M - Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion-Resistant, for General Application."

- International Organization for Standardization (ISO). "ISO 8062-3:2007: Geometrical product specifications (GPS) - Dimensional and geometrical tolerances for moulded parts - Part 3: General dimensional and geometrical tolerances and machining allowances for castings."

- ASM International. "ASM Handbook, Volume 15: Casting." Materials Park, OH: ASM International, 2008.

- Stainless Steel Industry Statistics and Market Analysis Reports (e.g., from Grand View Research or Allied Market Research reports on Global Metal Casting Market, various years).

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Precision Stainless Steel Casting | Durable Metal Components

Advancing Industrial Solutions with Stainless Steel Casting

The landscape of industrial manufacturing is continuously evolving, with a persistent demand for components that offer superior strength, durability, and corrosion resistance. In this high-stakes environment, stainless steel casting emerges as a pivotal technology, delivering unparalleled performance for critical applications. This specialized metal forming process enables the production of intricate parts capable of withstanding extreme conditions, from high temperatures and pressures to corrosive chemical environments. Its inherent properties make it indispensable across a multitude of sectors, driving innovation and reliability in essential infrastructure and machinery.

Recent industry trends highlight a significant uptick in the adoption of advanced casting techniques. The global market for metal castings, including both ferrous and non-ferrous alloys, is projected to grow steadily, driven by increased investments in infrastructure development, energy production, and the automotive sector. While `aluminum die casting` and `green sand metal casting` remain popular for specific applications due to their cost-effectiveness and rapid production cycles, the demand for `stainless steel casting` is experiencing robust growth, particularly for high-performance components where integrity and longevity are paramount. This trend is fueled by the need for enhanced material performance, tighter tolerances, and greater design flexibility, which traditional manufacturing methods often struggle to meet. The shift towards sustainable manufacturing practices also favors processes that produce durable, long-lasting components, reducing the need for frequent replacements and minimizing waste.

The Precision Manufacturing Process of Stainless Steel Casting

The creation of high-quality `metal castings`, particularly those from stainless steel, involves a meticulously controlled, multi-stage process designed to achieve specific metallurgical and dimensional characteristics. Unlike `aluminium metal casting` or `aluminum casting die` processes which often prioritize speed and lightweight properties, `stainless steel casting` focuses on achieving superior strength, corrosion resistance, and precision for demanding industrial applications. The typical process flow can be broken down into several critical steps:

1. Pattern Making

Creation of a replica of the desired part, typically from wax or other expendable materials. Critical for defining the final component's geometry and surface finish.

2. Molding & Shell Building

For investment casting, the wax pattern is repeatedly dipped into ceramic slurry and coated with refractory sand to build a strong ceramic shell. For sand casting, patterns are packed with sand.

3. Dewaxing/Mold Drying

The ceramic mold is heated to melt and remove the wax pattern, leaving a hollow cavity. Sand molds are dried and cored if necessary.

4. Melting & Pouring

High-grade stainless steel alloys (e.g., 304, 316, 17-4PH) are melted in induction furnaces, often under vacuum or inert atmosphere to prevent contamination. Molten metal is then poured into the preheated ceramic molds.

5. Solidification & Shakeout

The metal cools and solidifies within the mold. Once cooled, the ceramic shell is broken away (shakeout) to reveal the rough casting.

6. Finishing & Heat Treatment

Gates and risers are removed, and the casting is ground smooth. Heat treatments (e.g., annealing, solution treatment, precipitation hardening) are applied to optimize mechanical properties and stress relief.

7. Machining & Inspection

CNC machining for tight tolerances, followed by rigorous testing: NDT (X-ray, ultrasonic, MPI, LPI), dimensional inspection, mechanical testing, and chemical analysis. Products adhere to standards like ISO 9001, ASTM A743/A744, and ANSI.

The service life of components manufactured through this process, such as Cooling Flange Lowers and Bearing Housing Lowers, can extend decades, particularly in challenging environments like petrochemical plants or water supply & drainage systems, owing to their superior corrosion resistance and mechanical integrity. This longevity translates directly into significant energy saving and reduced maintenance costs over the lifecycle of the equipment.

Technical Specifications and Performance Parameters

Understanding the technical specifications of `stainless steel casting` is crucial for engineers and procurement professionals to ensure optimal performance in their applications. The choice of specific stainless steel grade significantly impacts mechanical properties, corrosion resistance, and suitability for various operating conditions. Here, we outline key parameters relevant to high-performance industrial components like Cooling Flanges and Bearing Housings.

Typical Stainless Steel Casting Grades and Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Key Characteristics |

|---|---|---|---|---|---|

| ASTM A743 Grade CF8 (304) | ≥ 485 | ≥ 205 | ≥ 35 | ≤ 190 | General corrosion resistance, good weldability, common in food/chemical. |

| ASTM A743 Grade CF8M (316) | ≥ 485 | ≥ 205 | ≥ 30 | ≤ 190 | Superior corrosion resistance, especially against chlorides, marine, pulp & paper. |

| ASTM A747 Grade CB7Cu-1 (17-4PH) | ≥ 930 | ≥ 725 | ≥ 8 | ≥ 290 | High strength and hardness, good corrosion resistance, aerospace, defense. |

Product Specification: Cooling Flange Lower & Bearing Housing Lower

These components, integral to various rotating machinery and fluid handling systems, demand exceptional material integrity and precise dimensions. For instance, a Cooling Flange Lower requires excellent thermal stability and corrosion resistance to manage temperature differentials effectively, while a Bearing Housing Lower needs robust mechanical strength and dimensional accuracy to ensure smooth operation and extended bearing life.

| Parameter | Cooling Flange Lower (Example) | Bearing Housing Lower (Example) |

|---|---|---|

| Material Grade | ASTM A743 Grade CF8M (316) | ASTM A743 Grade CF8 (304) |

| Weight Range | 0.5 kg - 50 kg | 1 kg - 100 kg |

| Dimensional Tolerance | ISO 8062 CT7-CT9 (as-cast) | ISO 8062 CT7-CT8 (as-cast) |

| Surface Finish | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) |

| Testing Standards | ISO 9001, ASTM E8 (Tensile), ASTM A370 (Hardness) | ISO 9001, ASTM E8 (Tensile), ASTM A370 (Hardness) |

| Heat Treatment | Solution Annealing | Solution Annealing |

Technical Advantages and Key Application Scenarios

The inherent properties of `stainless steel casting` offer a myriad of technical advantages, making it the material of choice for demanding industrial applications. These benefits translate directly into enhanced operational efficiency, reduced maintenance, and extended service life for critical components.

- Exceptional Corrosion Resistance: Stainless steels form a passive chromium oxide layer, providing superior resistance to oxidation, acids, alkalis, and chlorides. This is vital in environments like chemical processing, marine, and offshore oil and gas, where component integrity is constantly challenged by aggressive media. This characteristic far surpasses the resistance offered by many other `metal castings`.

- High Temperature Strength and Creep Resistance: Many stainless steel grades maintain their mechanical properties at elevated temperatures, making them suitable for furnace components, exhaust systems, and high-temperature fluid handling. This ensures structural integrity and dimensional stability under thermal stress.

- Superior Strength-to-Weight Ratio: Especially with duplex or precipitation-hardening grades, stainless steel offers high strength with relatively lower weight compared to some other alloys, contributing to more efficient designs and reduced static loads.

- Design Flexibility: The casting process allows for the production of complex geometries and intricate internal passages that would be difficult or impossible to achieve with forging or machining alone. This enables optimized designs for fluid dynamics, heat exchange, and component integration.

- Durability and Longevity: The combination of corrosion resistance, mechanical strength, and fatigue resistance results in components with extended service lives. This reduces downtime for repairs and replacements, leading to significant energy saving and lower lifecycle costs.

Target Industries and Application Examples:

- Petrochemical & Oil & Gas: Valve bodies, pump casings, impellers, Cooling Flange Lowers, and Bearing Housing Lowers used in refineries, offshore platforms, and chemical processing plants, where exposure to corrosive chemicals, high pressures, and extreme temperatures is constant. The corrosion resistance ensures reliable operation and prevents leaks.

- Metallurgy & Mining: Components for smelting furnaces, grinding mills, and material handling equipment that must withstand abrasive wear and high temperatures.

- Water Supply & Drainage: Pump components, fittings, and valve parts in water treatment plants and municipal infrastructure, where resistance to water, mild chemicals, and environmental factors is essential for long-term reliability.

- Marine Industry: Propeller components, pump casings, and other critical parts exposed to saltwater, requiring excellent pitting and crevice corrosion resistance.

- Food & Beverage: Hygienic fittings, valves, and machine parts requiring easy cleaning and resistance to cleaning agents, ensuring product safety and purity.

- Power Generation: Turbine components, heat exchanger parts, and valve systems in conventional and nuclear power plants, where high-temperature strength and corrosion resistance are non-negotiable.

Vendor Comparison and Customized Solutions in Casting

Selecting the right casting partner is as critical as choosing the right material. A competent vendor for `stainless steel casting` offers not just manufacturing capabilities but also engineering expertise, quality assurance, and the flexibility to provide customized solutions. This contrasts significantly with vendors primarily focused on high-volume, less complex processes like `aluminum die casting` or `green sand metal casting`.

Key Factors for Vendor Selection:

- Technical Expertise & Experience: A vendor's depth of knowledge in metallurgy, casting simulation software, and specific industry applications (e.g., petrochemical, marine) is crucial. Years of service and a robust portfolio of similar `metal castings` projects demonstrate experience.

- Quality Certifications: Adherence to international standards like ISO 9001, PED (Pressure Equipment Directive), and AD2000 for critical components. These certifications validate a commitment to consistent quality and process control.

- Manufacturing Capabilities: Assessing the range of casting processes (investment casting, sand casting), melting capacity, machining capabilities (CNC), and heat treatment options. The ability to handle diverse part sizes and complexities is key.

- Testing & Inspection Facilities: In-house NDT (Non-Destructive Testing) capabilities such as X-ray, ultrasonic, magnetic particle, liquid penetrant inspection, and robust CMM (Coordinate Measuring Machine) for dimensional verification.

- Supply Chain Reliability: A vendor's ability to manage raw material sourcing, production scheduling, and logistics to ensure on-time delivery and mitigate supply chain risks.

- Customer Support & Responsiveness: Proactive communication, quick response to inquiries, and dedicated project management.

Customized Solutions: Tailoring to Specific Needs

A superior casting partner goes beyond standard products, offering comprehensive customized solutions. This involves a collaborative approach from initial design to final production:

- Design for Manufacturability (DFM): Expert engineers work with clients to optimize part designs for the casting process, ensuring maximum efficiency, reduced material usage, and enhanced part performance while minimizing costs.

- Material Selection Expertise: Guiding clients in selecting the most appropriate stainless steel grade (e.g., austenitic, martensitic, duplex, precipitation hardening) based on the application's specific requirements for corrosion, temperature, and mechanical loads.

- Prototyping & Rapid Tooling: Offering fast prototyping services to validate designs and material performance before full-scale production.

- Specialized Heat Treatments: Tailoring heat treatment protocols (e.g., solution annealing, quenching and tempering, age hardening) to achieve precise mechanical properties for specialized applications.

- Advanced Finishing & Coating: Providing specialized surface finishes, coatings, or post-processing techniques (e.g., passivation, electropolishing) to further enhance corrosion resistance or reduce friction.

Real-World Application Case Studies

The versatility and robust performance of `stainless steel casting` are best illustrated through real-world applications where these components have delivered critical value. These case studies underscore the benefits of specialized `metal castings` in demanding industrial environments.

Case Study 1: High-Pressure Pump Casing for Chemical Processing

A leading chemical manufacturer faced persistent issues with premature failure of pump casings in a highly corrosive acid transfer system. Previous components, made from less resistant alloys, suffered from rapid pitting corrosion and stress cracking, leading to frequent downtime and high maintenance costs. Our solution involved designing and manufacturing a pump casing using ASTM A743 Grade CF8M (316 stainless steel) through precision investment casting. The complex internal geometries required for optimal fluid flow were achieved with exceptional accuracy. After deployment, the new `stainless steel casting` pump casing demonstrated a service life increase of over 300% compared to its predecessors, significantly reducing operational expenses and improving system reliability. The client reported a substantial energy saving due to reduced leakage and more efficient pump operation.

Case Study 2: Subsea Valve Components for Offshore Oil & Gas

For a critical subsea pipeline project, robust valve components were required to withstand extreme pressures, low temperatures, and aggressive saltwater conditions. Traditional manufacturing methods struggled to produce the intricate internal passages and precise dimensional tolerances necessary for reliable long-term operation at depths exceeding 1,000 meters. We utilized 17-4PH stainless steel `aluminium metal casting` for its superior strength and corrosion resistance. The investment casting process allowed for the creation of highly complex geometries with excellent surface finish, minimizing post-casting machining. Non-destructive testing, including X-ray and ultrasonic inspection, ensured absolute integrity. These components, including specialized Cooling Flange Lowers and Bearing Housing Lowers, have now been in continuous service for over five years without incident, demonstrating the unparalleled reliability of engineered `stainless steel casting` in extreme offshore environments.

Case Study 3: Bearing Housing for Industrial Water Treatment Pumps

An industrial water treatment facility required durable Bearing Housing Lowers for their large-scale centrifugal pumps. These housings were exposed to treated water containing various chemical additives and experienced constant vibration. Cast iron alternatives had issues with rust and premature wear, leading to frequent bearing replacements. We provided custom-designed Bearing Housing Lowers cast from ASTM A743 Grade CF8 (304 stainless steel). The key challenge was achieving tight concentricity and dimensional accuracy for bearing fitment to ensure smooth, vibration-free operation. Through precise CNC machining post-casting and stringent quality control, we delivered components that offered superior resistance to rust and wear. The new stainless steel housings extended bearing life by 50%, significantly reducing maintenance cycles and improving overall pump efficiency, contributing to an overall more sustainable and cost-effective operation for the client.

Commitment to Quality: Standards & Customer Trust

Our dedication to excellence in `stainless steel casting` is deeply rooted in upholding the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (). This commitment is paramount for B2B decision-makers seeking reliable, long-term partnerships.

Expertise & Authoritativeness:

- Certifications: We operate under stringent quality management systems, including ISO 9001:2015, ensuring consistent quality across all processes, from raw material inspection to final product delivery. Our facilities and products often comply with industry-specific standards like PED (Pressure Equipment Directive) and AD2000 for European markets.

- Years of Service: With over two decades of specialized experience in precision `metal castings`, we have developed unparalleled expertise in various alloys, including a wide range of stainless steels, for diverse industrial applications.

- Technical Staff: Our team comprises metallurgical engineers, casting specialists, and CNC programmers, continuously engaged in R&D to optimize casting parameters and material performance.

- Partner Clients: We proudly serve a global clientele, including leading companies in oil & gas, petrochemical, marine, and power generation sectors, who rely on our consistent quality and technical capabilities for their critical components.

Experience & Trustworthiness:

- Customer Feedback: "The precision and material integrity of the `stainless steel casting` components we received exceeded our expectations. Their technical support was invaluable throughout the project." - Senior Engineer, Global Pump Manufacturer.

- Comprehensive Testing: Every batch undergoes rigorous quality checks, including chemical composition analysis, mechanical property tests (tensile, hardness, impact), and non-destructive testing (NDT) such as X-ray and dye penetrant inspection, ensuring compliance with specified standards and customer requirements.

- Traceability: Full material and process traceability is maintained for all castings, from raw material melt number to final inspection reports, providing complete transparency and accountability.

Trust & Transparency: FAQ, Lead Time, Warranty & Support

Building and maintaining trust with our clients is fundamental to our operations. We ensure transparency in our processes, commitments, and support structures.

Frequently Asked Questions (FAQ):

Q: What are the primary advantages of `stainless steel casting` over other methods like forging?

A: Stainless steel casting excels in producing complex geometries and intricate internal features that are difficult or impossible to achieve through forging. It offers superior design flexibility and is often more cost-effective for medium to low volume production of complex parts. While forging offers directional grain flow for ultimate strength, casting allows for tailored metallurgical properties across the part.

Q: What grades of stainless steel do you typically work with?

A: We commonly work with a wide range of austenitic grades (e.g., 304/CF8, 316/CF8M, 304L, 316L), martensitic grades (e.g., 410, CA15), duplex grades (e.g., CD4MCu, 2205), and precipitation-hardening grades (e.g., 17-4PH/CB7Cu-1) to meet various application requirements for strength and corrosion resistance.

Q: Can you handle specialized post-processing requirements like passivation or electropolishing?

A: Yes, we offer comprehensive post-casting services including CNC machining, various heat treatments, surface finishing (e.g., shot blasting, vibratory finishing), and specialized treatments like passivation, electropolishing, and NACE compliance for enhanced corrosion resistance.

Lead Time & Fulfillment:

Our standard lead times are structured to ensure timely delivery without compromising quality. Tooling and prototyping typically take 4-8 weeks depending on complexity. Initial sample production and approval can range from 3-5 weeks. Once samples are approved, mass production lead times usually fall within 4-10 weeks, varying based on order volume, part complexity, and material availability. We employ robust production planning and inventory management systems to meet client schedules efficiently.

Warranty Commitments:

We stand behind the quality of our `metal castings`. All products are manufactured to agreed-upon specifications and international standards. We offer a comprehensive warranty against defects in material and workmanship, typically for 12 months from the date of shipment. Our commitment is to ensure that every component performs as expected in its intended application.

Customer Support & After-Sales Service:

Our dedication extends beyond delivery. We provide continuous technical support, including assistance with material selection, design optimization, and troubleshooting. Our dedicated account managers ensure prompt communication and swift resolution of any inquiries or challenges. We are committed to building long-term partnerships based on mutual trust and sustained performance.

Conclusion and References

In an industrial landscape that increasingly demands reliability, efficiency, and longevity, `stainless steel casting` stands out as a superior manufacturing solution. Its unique combination of corrosion resistance, mechanical strength, and design flexibility positions it as an indispensable process for critical components across diverse sectors. From petrochemical and marine applications to water treatment and general industrial machinery, precision `stainless steel casting` delivers performance that translates into significant operational advantages, extended service life, and a lower total cost of ownership. Partnering with an experienced and technically proficient casting provider ensures access to not only high-quality parts like Cooling Flange Lowers and Bearing Housing Lowers but also to comprehensive engineering support and customized solutions tailored to specific project requirements.

References:

- American Society for Testing and Materials (ASTM). "ASTM A743/A743M - Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion-Resistant, for General Application."

- International Organization for Standardization (ISO). "ISO 8062-3:2007: Geometrical product specifications (GPS) - Dimensional and geometrical tolerances for moulded parts - Part 3: General dimensional and geometrical tolerances and machining allowances for castings."

- ASM International. "ASM Handbook, Volume 15: Casting." Materials Park, OH: ASM International, 2008.

- Stainless Steel Industry Statistics and Market Analysis Reports (e.g., from Grand View Research or Allied Market Research reports on Global Metal Casting Market, various years).

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025