Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 20, 2025 16:37

Back to list

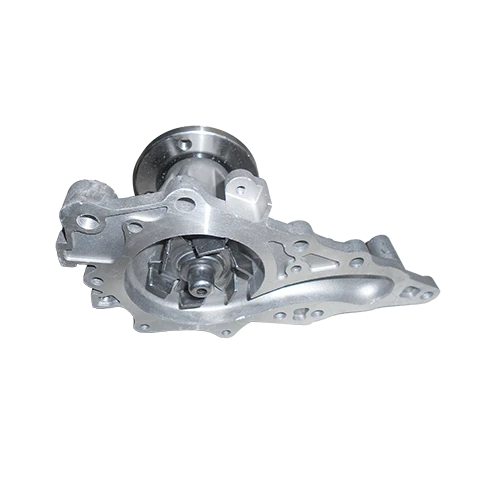

Pump Body

In the realm of piping systems, the pipe blanking cap stands as a small yet significant component. Meticulously designed to seal the ends of tubes and pipes, it is the unsung hero that contributes to safety, efficiency, and integrity in fluid conveyance systems across diverse industries. Understanding the nuances of the pipe blanking cap not only aids in choosing the right product for your needs but also underscores its vital role in ensuring system robustness.

Authoritatively speaking, industry standards such as those set by ASTM and ISO provide guidelines for the manufacture and testing of pipe blanking caps. Compliance with these standards guarantees that the products meet fundamental safety and quality thresholds, fostering trust in their performance. For practitioners and engineers, selecting products from manufacturers that adhere to these standards is not just a matter of compliance but of ensuring reliability and safety in their systems. Trustworthiness in the use of pipe blanking caps is further reinforced by the reputation of the manufacturer. Companies with a long-standing history in producing high-quality piping components often provide additional assurance through extended warranties and responsive customer support. This offers peace of mind, knowing that any issues encountered can be swiftly and effectively addressed. In real-world applications, the importance of the pipe blanking cap cannot be underestimated. Consider its role in food processing plants where hygiene is paramount. Here, the cap not only ensures the absence of contamination but also aids in the modulation of system expansion and contraction due to temperature variations. Its role is pivotal in maintaining operational consistency and meeting stringent health standards. In conclusion, the pipe blanking cap might appear to be a minor player in the grand scheme of piping systems, but its impact on system longevity, safety, and efficiency is significant. Professionals must leverage their expertise to select and apply these components judiciously, guided by a comprehensive understanding of material properties, environmental factors, and industry standards. As a cornerstone of effective fluid management systems, the pipe blanking cap exemplifies how attention to detail in component selection can lead to superior system performance and reliability.

Authoritatively speaking, industry standards such as those set by ASTM and ISO provide guidelines for the manufacture and testing of pipe blanking caps. Compliance with these standards guarantees that the products meet fundamental safety and quality thresholds, fostering trust in their performance. For practitioners and engineers, selecting products from manufacturers that adhere to these standards is not just a matter of compliance but of ensuring reliability and safety in their systems. Trustworthiness in the use of pipe blanking caps is further reinforced by the reputation of the manufacturer. Companies with a long-standing history in producing high-quality piping components often provide additional assurance through extended warranties and responsive customer support. This offers peace of mind, knowing that any issues encountered can be swiftly and effectively addressed. In real-world applications, the importance of the pipe blanking cap cannot be underestimated. Consider its role in food processing plants where hygiene is paramount. Here, the cap not only ensures the absence of contamination but also aids in the modulation of system expansion and contraction due to temperature variations. Its role is pivotal in maintaining operational consistency and meeting stringent health standards. In conclusion, the pipe blanking cap might appear to be a minor player in the grand scheme of piping systems, but its impact on system longevity, safety, and efficiency is significant. Professionals must leverage their expertise to select and apply these components judiciously, guided by a comprehensive understanding of material properties, environmental factors, and industry standards. As a cornerstone of effective fluid management systems, the pipe blanking cap exemplifies how attention to detail in component selection can lead to superior system performance and reliability.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS