Mobile:+86-311-808-126-83

Email:info@ydcastings.com

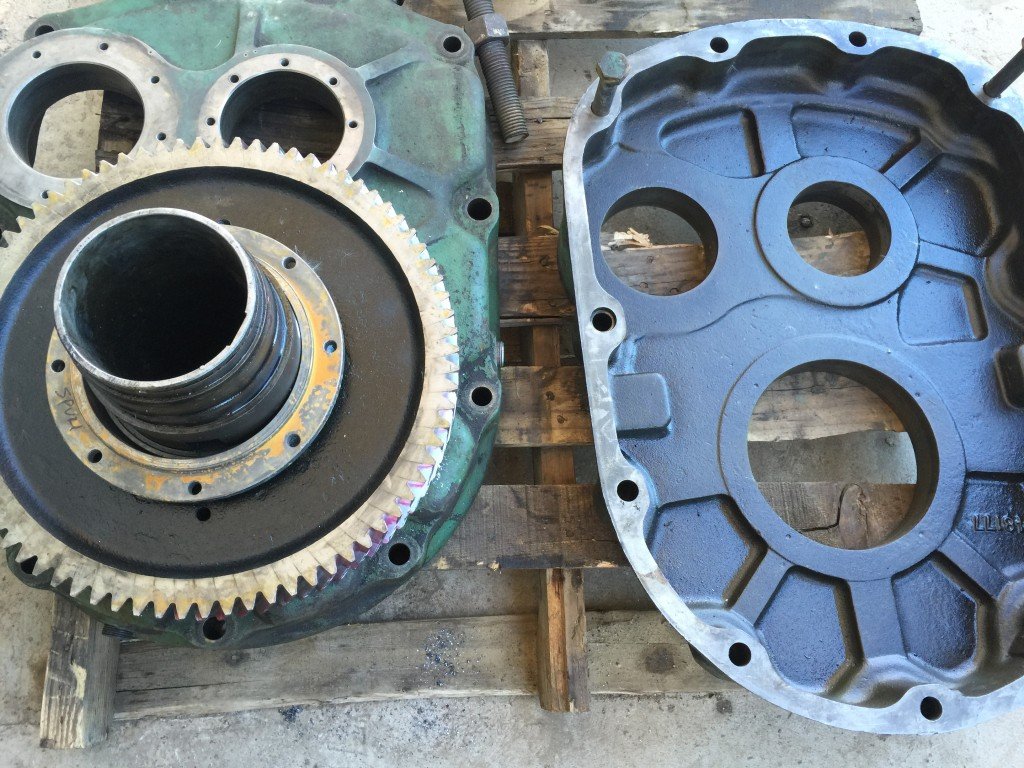

motor housing

Understanding Motor Housing The Essential Component in Electric Motors

Motor housing is a critical component of electric motors, serving not only to protect the internal mechanisms but also to enhance the overall efficiency and performance of the motor. In this article, we will explore the significance of motor housing, its design considerations, materials used, and its impact on the functionality and durability of electric motors.

The Importance of Motor Housing

Motor housing acts as a protective shell that encases the motor's critical components, including the stator, rotor, and various electrical connections. By providing a barrier against environmental factors such as dust, moisture, and mechanical impacts, the housing ensures the longevity of the motor and minimizes maintenance needs. In many applications, motors are exposed to harsh conditions, whether in automotive, industrial, or domestic settings; therefore, robust housing is essential for reliable performance.

Moreover, motor housing plays a crucial role in heat dissipation. Electric motors generate heat during operation; without proper ventilation and cooling, excessive heat can lead to inefficiency and even motor failure. To counter this, many motor housings are designed with built-in cooling features, such as vents or fins, that allow heat to escape more effectively.

Design Considerations

When designing motor housing, several factors must be taken into account. One of the primary considerations is the motor's intended application. For instance, motors used in high-speed applications may require different housing features compared to those in low-speed, high-torque settings. Additionally, the size and weight of the motor largely depend on the housing design, which must ensure that the motor remains compact yet capable of withstanding operational stresses.

motor housing

Sealing is another critical aspect of motor housing design. Effective sealing prevents the ingress of contaminants that could harm internal components. Various sealing methods, such as gaskets and O-rings, are employed to achieve the desired level of protection. The degree of sealing required can vary based on the application—marine environments, for example, necessitate much tighter seals than those found in dry industrial settings.

Material Selection

The choice of materials for motor housing is fundamental to achieving the desired durability and performance. Common materials include aluminum, steel, and various polymers. Aluminum is favored for its lightweight and corrosion-resistant properties, making it ideal for many applications where weight plays a crucial role. Steel, on the other hand, offers enhanced strength and durability, important for heavy-duty motors that endure significant physical stress.

In more specialized scenarios, composite materials may also be utilized. These materials can provide a balance of strength, weight, and thermal resistance, especially in motors designed for aerospace or automotive use where performance is critical.

The Impact of Motor Housing on Performance

The relationship between motor housing and performance cannot be overstated. A well-designed housing can optimize efficiency by reducing energy losses and enhancing cooling. Furthermore, the structural integrity provided by robust housing can minimize vibrations, which can have detrimental effects on both performance and longevity.

In conclusion, motor housing is much more than just an outer shell; it is an integral part of the electric motor that affects its performance, efficiency, and lifespan. As technology advances and the demand for higher-performing motors increases, the design and engineering of motor housings continue to evolve. By focusing on innovative materials and designs, engineers can create motor housings that not only protect internal components but also contribute significantly to the overall effectiveness of electric motors in various applications. Ultimately, investing in quality motor housing is essential for maximizing the potential of electrical machinery.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025