Mobile:+86-311-808-126-83

Email:info@ydcastings.com

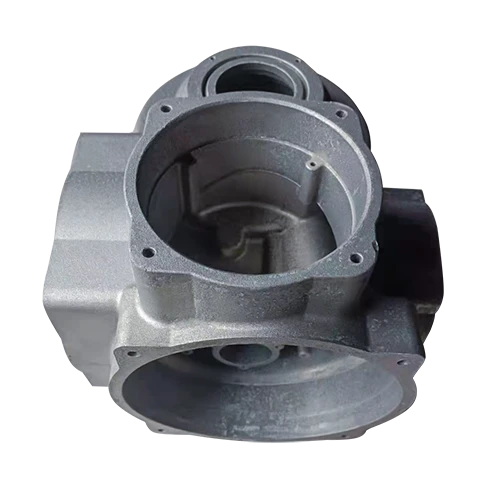

motor bearing housing

The Importance of Motor Bearing Housings in Machinery

Motor bearing housings play a crucial role in the functionality and longevity of various machinery that rely on rotating components. These housings provide essential support and protection for the bearings, ensuring smooth operation while minimizing wear and tear. In this article, we will explore the significance of motor bearing housings, their design considerations, and their impact on overall machine performance.

Understanding Motor Bearing Housings

At its core, a motor bearing housing is a protective enclosure that holds the bearings in place, allowing for the smooth rotation of shafts. Bearings are critical components in motors and other machinery, as they reduce friction between moving parts, enabling efficient performance. Without a suitable housing, bearings would be exposed to contaminants like dust, dirt, and moisture, which can significantly compromise their functionality.

Design Considerations

When designing motor bearing housings, several factors must be taken into account

1. Material Selection The material used for the housing must be durable and able to withstand various environmental conditions. Common materials include cast iron, aluminum, and stainless steel, each offering distinct advantages in terms of strength, weight, and resistance to corrosion.

2. Dimensions and Fit The housing's dimensions must align precisely with the bearings and other components. Proper fit is essential to reduce vibrations and noise during operation. Additionally, the housing must accommodate thermal expansion and contraction, ensuring that the bearings remain securely in place under varying temperatures.

motor bearing housing

3. Sealing and Protection Effective sealing mechanisms are vital to protect the bearings from external contaminants. Seals also prevent lubricant leakage, which can lead to accelerated wear. Designs often incorporate features like lip seals or labyrinth seals to enhance protection.

4. Cooling and Lubrication Many motors generate significant heat during operation, making it essential to incorporate effective cooling solutions within the design of the housing. Lubrication systems, whether grease or oil-based, should also be considered to ensure that the bearings remain well-lubricated throughout their operational life.

Impact on Machine Performance

The performance of a motor and its efficiency are directly influenced by the design and quality of the bearing housing. A well-designed housing minimizes friction and vibration, which contributes to smoother operation and reduced energy consumption. Additionally, it extends the service life of the bearings, thereby decreasing maintenance costs and downtime.

Furthermore, the reliability of machinery greatly increases when proper attention is given to bearing housing design. In industries such as manufacturing, automotive, and aerospace, any failure in the motor bearings can lead to significant operational disruptions. Therefore, investing in quality motor bearing housings is not only a matter of efficiency but also of safety and reliability.

Conclusion

Motor bearing housings may appear to be simple components, but they are integral to the overall function and longevity of rotating machinery. By placing emphasis on proper design, material selection, and protective features, manufacturers can ensure that their machines operate efficiently and securely. As technology advances, continuous improvements in housing design and materials will likely lead to even better performance and reliability, paving the way for enhanced machinery in various industries.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025