Mobile:+86-311-808-126-83

Email:info@ydcastings.com

metal casting process

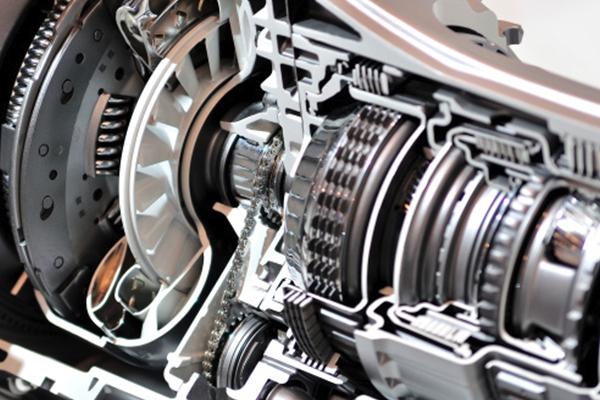

Understanding the Metal Casting Process

Metal casting is one of the oldest manufacturing processes known to humankind, dating back thousands of years. It involves pouring liquid metal into a mold to solidify and form a specific shape. This versatile and efficient technique is used in a myriad of applications, ranging from automotive components to intricate art pieces, making it a critical process in various industries. In this article, we will explore the essential aspects of metal casting, including its types, advantages, and applications.

Types of Metal Casting Processes

There are several different types of casting methods, each suited for specific applications and materials. The most notable include

1. Sand Casting This is the most common method. It involves creating a mold from fine sand and a binding agent, typically clay. Once the mold is created, molten metal is poured in, and after it cools, the mold is broken away to reveal the cast part. Sand casting is favored for its flexibility and low cost.

2. Investment Casting Also known as lost-wax casting, this method involves coating a pattern made of wax (or another material) with a heat-resistant ceramic shell. Once the shell hardens, the wax is melted away, leaving a hollow mold. This process is excellent for producing precise and intricate components, often used in the aerospace and jewelry industries.

3. Die Casting In die casting, molten metal is injected into a reusable steel mold under high pressure. This method is ideal for producing large quantities of small to medium-sized parts with a high degree of accuracy and smooth finishes. It's commonly used in the automotive and electronics sectors.

4. Continuous Casting This process involves solidifying molten metal into a continuous length, producing billets and slabs used in further processing. Continuous casting is widely used in the production of steel and aluminum.

5. Shell Molding This method combines the benefits of sand and investment casting. A thin shell is formed using sand and resin, which is then filled with molten metal. Shell molding allows for improved surface finish and dimensional accuracy.

Advantages of Metal Casting

metal casting process

Metal casting offers several benefits, making it a preferred manufacturing method for many applications

. Some of the main advantages include- Complex Shapes Casting allows for the easy creation of intricate designs that would be challenging or impossible to achieve with other manufacturing techniques. - Material Versatility A wide variety of metals can be cast, including aluminum, bronze, iron, and magnesium, allowing for tailored mechanical properties according to application needs.

- Cost-Effectiveness For large production volumes, casting can be more economically viable compared to techniques like machining or fabrication, especially when it comes to the raw material usage and production time.

- Reduced Waste The casting process generates minimal waste compared to machining, where excess material is often cut away and discarded.

- High-Quality Finishes Certain casting methods, like die casting and investment casting, result in high-quality finishes that require little to no further processing.

Applications of Metal Casting

Metal casting finds application across various industries. In the automotive industry, it is used to manufacture engine blocks, cylinder heads, and other critical components. The aerospace sector employs casting for turbine blades and other intricate parts that must withstand extreme conditions. In the construction industry, cast metal components such as girders and columns provide structural support.

Additionally, art foundry work utilizes metal casting for sculptures, highlighting the technique's versatility beyond industrial applications. As technology evolves, the integration of computer-aided design (CAD) systems and additive manufacturing within casting processes continues to expand its potential.

Conclusion

The metal casting process remains an integral part of modern manufacturing, providing a practical solution for producing complex shapes with high precision and minimal waste. Whether through sand casting, investment casting, die casting, or other methods, the techniques have evolved while maintaining their core principle—transforming molten metal into functional and aesthetic products. As industries continue to innovate, metal casting will adapt to meet new challenges, ensuring its relevance well into the future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025