Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

metal casting for beginners

An Introduction to Metal Casting for Beginners

Metal casting is a fascinating and ancient technique that transforms molten metal into usable shapes and products. For beginners, the world of metal casting can seem daunting, filled with complex processes and terminology. However, with the right knowledge and a bit of practice, anyone can learn the basics of this craft and create stunning metal pieces.

What is Metal Casting?

Metal casting involves pouring molten metal into a mold, allowing it to solidify into a predetermined shape. This age-old technique has been utilized for thousands of years, producing everything from decorative items to critical industrial components. Understanding the basic principles of casting can open doors to many creative and practical projects.

Basic Materials Used in Casting

To get started with metal casting, you'll need a few essential materials

1. Metal Common metals used in casting include aluminum, bronze, and brass, which have relatively low melting points and are easier to work with for beginners.

2. Molds Molds can be made from various materials, including sand, metal, or ceramic. Sand molds are popular for beginners due to their simplicity and low cost.

3. Flux Flux is a chemical cleaning agent added to molten metal to remove impurities, ensuring a smoother final product.

The Casting Process

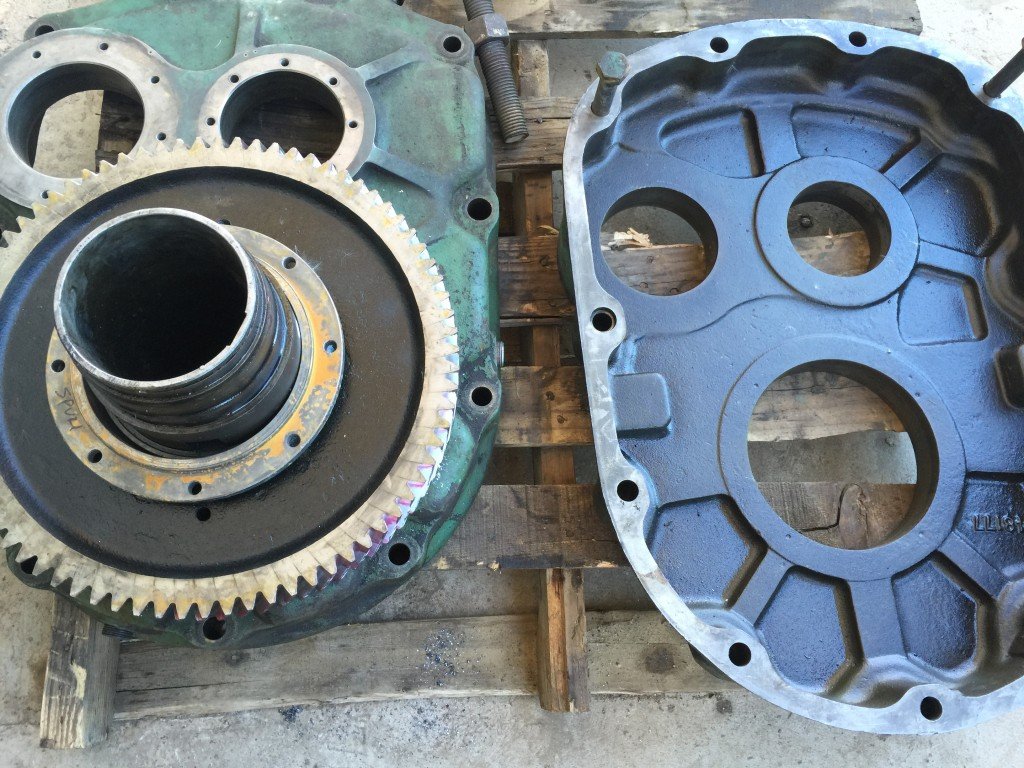

metal casting for beginners

The metal casting process can be broken down into several key steps

1. Creating a Pattern Begin with a pattern, which is a replica of the final desired product. Patterns can be made from wood, plastic, or metal. Ensure the pattern has a slight draft to facilitate easy removal from the mold.

2. Making the Mold The next step is creating a mold from your pattern. If using sand, compact the sand around the pattern and remove the pattern to leave a cavity. For more complex shapes, consider using plaster or metal molds.

3. Melting the Metal The metal should be heated in a furnace until it reaches a molten state. Each metal has its own melting temperature, so be sure to follow guidelines for the specific metal you are working with.

4. Pouring the Metal Carefully pour the molten metal into the prepared mold. This step requires precision and safety precautions, as molten metal is extremely hot and can cause severe burns.

5. Cooling and Finishing After the metal has cooled and solidified, carefully remove it from the mold. This may involve breaking the sand mold or releasing it from a metal casing. Once removed, you can finish the piece using tools to grind, polish, or shape it further.

Safety First

Safety is paramount when engaging in metal casting. Always wear protective gear, including heat-resistant gloves, goggles, and a face shield. Make sure your workspace is well-ventilated and free from flammable materials.

Conclusion

Metal casting is an exhilarating way to express creativity while learning a valuable skill. By starting with small projects and gradually progressing to more complex designs, beginners can hone their craft and potentially explore various applications within the world of metalworking. With patience and practice, you can create beautiful, one-of-a-kind metal pieces that reflect your artistic vision. So gather your materials, prioritize safety, and dive into the captivating realm of metal casting!

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025