Mobile:+86-311-808-126-83

Email:info@ydcastings.com

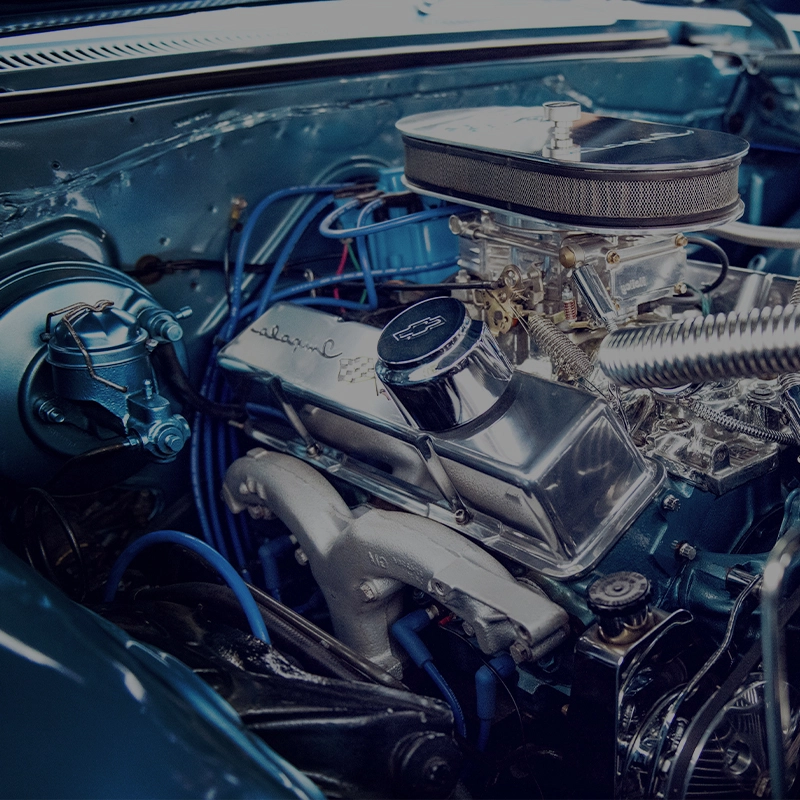

Metal Casting Moulds - Precision and Quality for Your Casting Needs

Metal Casting Moulds An Essential Tool in Manufacturing

Metal casting is a fundamental process in the manufacturing industry, allowing for the creation of intricate parts and components used in various applications. At the heart of this process lies the casting mould, a pivotal tool that shapes the molten metal into the desired form. Understanding the types, materials, and significance of metal casting moulds is essential for anyone involved in metalworking.

Types of Casting Moulds

There are several types of metal casting moulds, each suited for specific applications

. The most common types include sand moulds, metal moulds, investment moulds, and permanent moulds.1. Sand Moulds These are made from a mixture of sand, clay, and water. Sand moulds are versatile and inexpensive, making them a popular choice for many foundries. They can be easily shaped and are ideal for producing complex geometries.

2. Metal Moulds Often referred to as die casting, metal moulds are made from high-strength metals such as steel or aluminum. They are used for high-volume production due to their durability and ability to withstand high temperatures. Metal moulds offer excellent surface finish and dimensional accuracy.

3. Investment Moulds Also known as lost-wax casting, investment moulds are made from a wax pattern coated in a refractory ceramic material. This method produces detailed and intricate parts but is suitable for lower production volumes due to the higher costs involved.

metal casting moulds

4. Permanent Moulds These moulds are made from metal and can be reused multiple times. They are particularly effective for casting non-ferrous metals and contribute to improved production efficiency.

Materials Used for Moulds

The choice of materials for casting moulds significantly affects the quality of the final product. Sand, resin, metal, and ceramic are among the most commonly used materials. The selection depends on factors such as the type of metal being cast, the complexity of the design, and the production volume required.

The Importance of Casting Moulds

Casting moulds play a critical role in determining the quality and precision of the final metal castings. A well-designed mould can significantly reduce the amount of waste material and processing time while enhancing the overall integrity of the product. The ability to produce complex shapes with tight tolerances makes casting moulds invaluable in industries ranging from automotive to aerospace.

In conclusion, metal casting moulds are an essential component of the manufacturing process, offering versatility and precision in producing high-quality castings. As technology advances, innovations in mould design and materials continue to improve efficiency and reduce costs, ensuring that metal casting remains a vital resource in modern manufacturing. Understanding the types and significance of these moulds is crucial for anyone looking to excel in the field of metalworking.