Mobile:+86-311-808-126-83

Email:info@ydcastings.com

investment cast 316 stainless steel

Investment Casting of 316 Stainless Steel An Overview

Investment casting, a precision casting method also known as lost-wax casting, has gained significant popularity in various industries due to its ability to produce complex shapes with excellent surface finish and accuracy. Among the metals commonly used in investment casting, 316 stainless steel stands out due to its remarkable properties, making it an ideal choice for a wide range of applications.

What is 316 Stainless Steel?

316 stainless steel is an austenitic alloy known for its durability and resistance to corrosion. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments. This steel grade is widely used in marine applications, chemical processing, and medical devices due to its ability to withstand extreme environments. In investment casting, 316 stainless steel is favored for its strength, toughness, and excellent weldability.

The Investment Casting Process

The investment casting process begins with the creation of a wax pattern that resembles the desired final product. This pattern is coated with a heat-resistant ceramic shell, and the assembly is then heated to remove the wax, leaving a cavity in the shape of the pattern. The molten 316 stainless steel is poured into this cavity, allowing the material to flow into intricate details of the design. Once cooled, the ceramic shell is broken away, revealing the cast part.

This process enables the production of components with complex geometries and tight tolerances that would be difficult or impossible to achieve with traditional machining techniques. The ability to cast thin walls and fine details also contributes to material savings and reduced overall weight in the final product.

investment cast 316 stainless steel

Advantages of Using 316 Stainless Steel in Investment Casting

1. Corrosion Resistance The primary advantage of selecting 316 stainless steel for investment casting is its superior resistance to corrosion. This makes it suitable for components exposed to harsh environments, whether in marine applications or chemical facilities.

2. High Strength and Durability 316 stainless steel exhibits excellent mechanical properties, including high tensile strength and toughness, even at elevated temperatures. This ensures that the cast components maintain their integrity under stress.

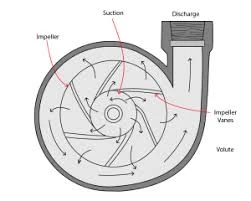

3. Versatile Applications The versatility of 316 stainless steel allows it to be used in various industries, including aerospace, automotive, oil and gas, and medical sectors. Components such as valves, pump housings, and surgical instruments can be efficiently manufactured using this method.

4. Cost-Effective Production Although the initial setup for investment casting may be higher compared to other methods, the production of large volumes of parts can be more economical in the long run. Reduced waste and the ability to consolidate multiple components into a single cast part contribute to overall cost savings.

Conclusion

In summary, the investment casting of 316 stainless steel is a highly effective method for producing complex and durable components. Its unique properties, combined with the precision of the investment casting process, make it an excellent choice for a variety of demanding applications. As industries continue to seek solutions that deliver both performance and efficiency, investment casting with 316 stainless steel will undoubtedly remain a key player in advanced manufacturing.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025