Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Investment Casting Techniques for Impeller Production in Modern Manufacturing

The Significance of Impeller Investment Casting in Modern Manufacturing

In the ever-evolving landscape of manufacturing, precision and efficiency hold the key to competitiveness. Among various techniques, investment casting has emerged as a cornerstone process, especially in the context of producing complex components like impellers. This article delves into the significance of impeller investment casting and its impact on diverse industries.

What is Investment Casting?

Investment casting, often referred to as lost-wax casting, is a manufacturing process that allows for the production of intricate and high-precision parts. The process begins with creating a wax pattern of the desired component, which is then surrounded by a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a cavity that matches the pattern. Molten metal is subsequently poured into this cavity to create the final product. This technique is particularly beneficial for complex geometries and tight tolerances, which are essential in industries such as aerospace, automotive, and energy.

Application in Impeller Production

Impellers are critical components in various applications, including turbines, pumps, and compressors. Their design is pivotal to the efficiency of fluid dynamics, making them essential in sectors like aerospace and automotive engineering. The intricate shapes and fine details required for impellers make investment casting an ideal method for their production.

One of the remarkable advantages of impeller investment casting is the ability to produce parts with superior surface finishes and dimensional accuracy. Unlike traditional machining methods, which may require extensive finishing processes, investment casting allows manufacturers to achieve closer tolerances right after the casting process. This ability not only reduces production time but also minimizes material waste, aligning with modern sustainable manufacturing practices.

Benefits of Investment Casting for Impellers

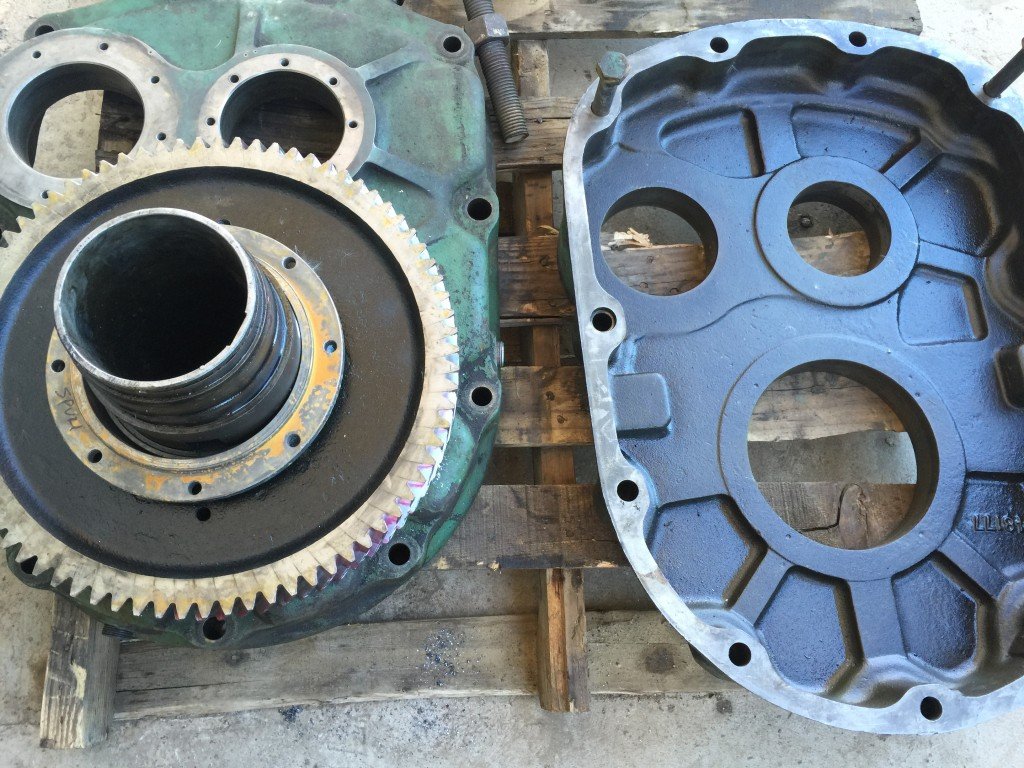

impeller investment casting

1. Design Flexibility Investment casting offers unparalleled design freedom, enabling engineers to create complex geometries that are often impossible to achieve with other methods. This flexibility is crucial for optimizing impeller designs to enhance performance and efficiency.

2. Material Versatility This casting technique accommodates a wide range of materials, including various aluminum, stainless steel, and nickel-based alloys. This versatility allows manufacturers to select materials that best suit the operational conditions of the impellers, such as high temperatures and corrosive environments.

3. Consistency and Reproducibility Investment casting provides a high level of consistency across production runs. This reproducibility is vital for industries where performance cannot be compromised. Manufacturers can produce thousands of identical parts without significant variations.

4. Reduced Lead Time The investment casting process typically involves fewer steps than traditional manufacturing methods. This reduction in complexity often leads to shorter lead times, allowing companies to respond quickly to market demands.

Challenges and Solutions

Despite its numerous advantages, investment casting does come with challenges, such as potential issues with porosity and surface defects. However, advancements in technology and quality control measures have significantly mitigated these problems. Innovations in simulation software enable manufacturers to predict flow patterns and solidification, thereby optimizing the design and reducing the likelihood of defects.

Conclusion

The role of impeller investment casting in modern manufacturing cannot be overstated. It epitomizes the fusion of innovation and functionality, offering solutions that are both efficient and precise. As industries continue to demand higher performance and lower costs, investment casting will undoubtedly remain at the forefront of producing critical components like impellers. Through ongoing advancements and a commitment to excellence, this technique will continue to shape the future of manufacturing across various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025