Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Innovative Approaches to Bearing Housing Casting Techniques for Enhanced Durability and Performance

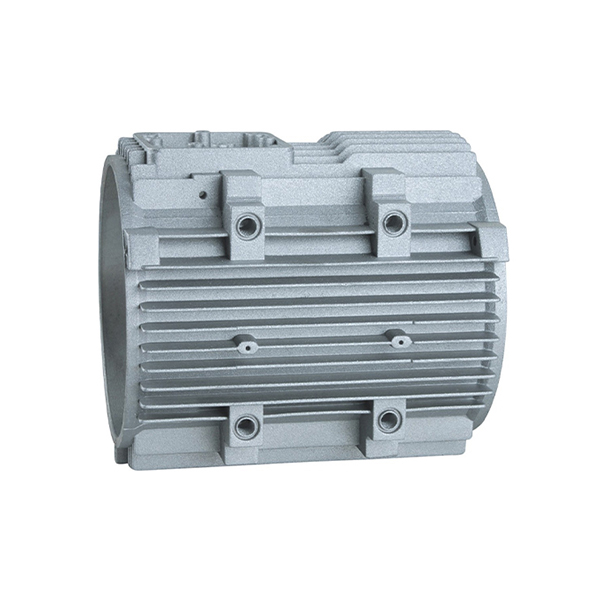

Bearing Housing Casting An Overview of Its Significance and Applications

Bearing housing casting is an essential process in the manufacturing of various machinery components. It serves as a protective enclosure for bearings, which are critical for reducing friction and facilitating smooth movement in rotating or sliding applications. The significance of bearing housing casting extends across diverse industries, ranging from automotive to aerospace, and from industrial machinery to consumer goods.

The Casting Process

The casting process involves pouring molten metal into a mold to form the desired shape once it cools and solidifies. In the case of bearing housings, various materials can be utilized, including cast iron, aluminum, and magnesium alloys. Each material has its unique properties that make it suitable for specific applications. For instance, cast iron is renowned for its durability and vibration-damping characteristics, making it a popular choice in heavy machinery. In contrast, aluminum is favored for its lightweight properties, which are crucial in applications where weight reduction is paramount.

The casting process can be broken down into several key steps

1. Pattern Making A pattern of the bearing housing is created, often out of wood or plastic. This pattern will be used to form the mold.

2. Mold Creation The pattern is placed in a sand mixture to create a mold. This step often involves compacting sand around the pattern to ensure the details are captured accurately.

3. Melting The chosen metal is melted in a furnace to a specific temperature, ensuring it becomes fully liquid.

bearing housing casting

5. Cooling The metal cools and solidifies in the mold.

6. Finishing Once cooled, the mold is removed, and secondary processes such as machining, cleaning, and surface treatment may be applied to achieve the desired dimensions and finish.

Applications in Various Industries

Bearing housings are integral components in machinery that require reliable rotational or linear motion. In the automotive industry, they house wheel bearings, transmission components, and driveshafts, enhancing vehicle performance and longevity. In industrial settings, bearing housings are used in conveyor systems, motors, and pumps. Their robust design can withstand hefty loads and harsh operating conditions, thereby contributing to the efficiency of the overall machinery.

In the aerospace sector, precision is paramount. Lightweight bearing housings made from advanced materials are designed to meet strict weight requirements without compromising safety or functionality. This necessity drives innovation and research into new alloys and advanced manufacturing techniques.

Advantages of Casting Over Other Manufacturing Processes

Casting offers several advantages compared to other manufacturing techniques, such as machining or forging. It allows for complex shapes and designs that would be difficult or impossible to achieve through traditional methods. Additionally, casting is often more cost-effective for mass production, as it minimizes material waste and shortens production cycles. The ability to incorporate intricate features directly into the casting also reduces the need for extensive secondary operations, thereby saving time and labor costs.

Conclusion

In conclusion, bearing housing casting plays a pivotal role in numerous applications across various industries. Its ability to deliver durable, lightweight, and complex components makes it an indispensable process in modern manufacturing. As technology advances and industries evolve, the importance of efficient and effective bearing housing casting will continue to grow, ensuring that machinery operates smoothly and reliably in an increasingly demanding world.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025