Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding Impeller Suction Mechanisms in Pump Design and Performance Optimization

Understanding Impeller Suction Fundamentals and Applications

Impeller suction is a crucial concept in fluid dynamics, especially in the context of pumps and industrial machinery. It refers to the ability of an impeller, a rotating component within a pump, to draw fluid into the pump casing and maintain an effective flow rate. To grasp the importance of impeller suction, it is essential to dissect several components, including its design, operational principles, and applications across various industries.

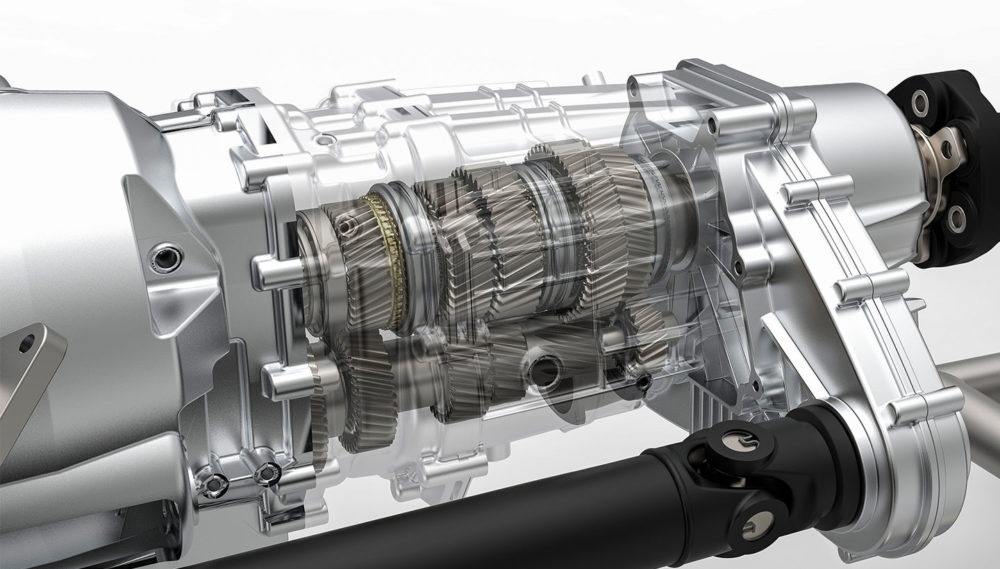

At the core of any centrifugal pump is the impeller. This component consists of blades that convert mechanical energy from a motor into kinetic energy in the fluid. As the impeller spins, it creates a low-pressure zone at the inlet. This reduction in pressure allows atmospheric pressure or pressure from the source fluid to push the liquid into the pump. The efficiency of this suction process largely depends on the impeller's design, including blade shape, number, and size. Each of these factors directly influences how effectively the pump can draw in fluid under varying operational conditions.

One significant aspect of impeller suction is its relationship with the Net Positive Suction Head (NPSH). NPSH is a critical parameter that defines the pressure required to prevent the liquid from vaporizing as it enters the pump. If the NPSH available is lower than the NPSH required, cavitation can occur. Cavitation is a phenomenon where vapor bubbles form in the fluid due to low pressure, which, upon collapsing, can cause severe damage to the impeller and other pump components. Therefore, understanding and managing NPSH is vital for any system that utilizes impeller suction.

impeller suction

In practical applications, impeller suction plays a vital role in various industries, including water treatment, petrochemical processing, and food and beverage manufacturing. For instance, in wastewater treatment facilities, pumps with efficient impeller suction systems are essential to transport large volumes of liquid through various treatment stages. Similarly, in the oil and gas industry, pumps equipped with robust impellers ensure the efficient extraction and transportation of crude oil and other fluids from deep within the Earth.

Moreover, advancements in technology have led to the development of specialized impellers designed for specific applications. For example, vortex impellers are designed to minimize the potential for cavitation, while multi-channel impellers are engineered for increased flow rates in high viscosity fluids. By employing these specialized designs, industries can enhance efficiency and reliability in fluid transport systems.

In conclusion, the principles of impeller suction are foundational to the operation of many mechanical systems involving fluid movement. As industries continue to evolve and demand greater efficiency and accuracy in fluid handling, enhancing impeller designs and understanding their suction characteristics will be more crucial than ever. Whether in the context of optimizing existing systems or developing new technologies, the significance of impeller suction remains paramount in driving innovation and efficiency across multiple sectors.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025