Mobile:+86-311-808-126-83

Email:info@ydcastings.com

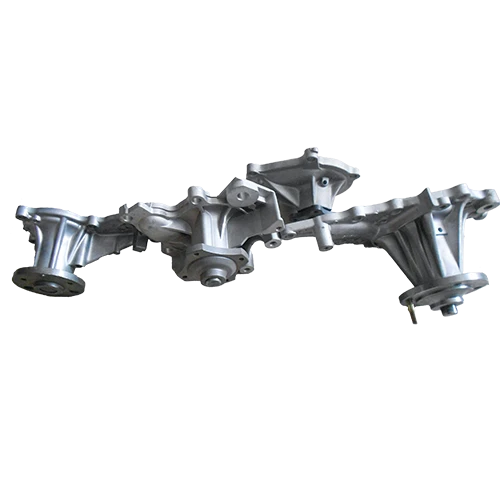

impeller stainless steel

The Significance of Stainless Steel Impellers in Modern Engineering

In the realm of engineering and manufacturing, stainless steel impellers play a crucial role across various applications, ranging from automotive to chemical processing. An impeller is a rotating component designed to enhance the flow and pressure of fluids, and when constructed from stainless steel, it offers several advantages that make it the material of choice for many engineers and manufacturers.

Durability and Corrosion Resistance

One of the primary advantages of stainless steel impellers is their remarkable durability and resistance to corrosion. Stainless steel, an alloy primarily made of iron, chromium, and nickel, exhibits exceptional strength and longevity, making it an ideal material for environments where resistance to harsh conditions is essential. In industries such as marine, chemical, and food processing, impellers made from stainless steel are less likely to degrade or corrode over time, leading to longer operational lifespans and reduced maintenance costs.

The ability of stainless steel to resist oxidation and rust is particularly important in applications involving water or corrosive chemicals. For instance, in wastewater treatment plants, impellers are constantly exposed to varying temperatures, pH levels, and chemicals. Stainless steel impellers ensure reliable performance under these challenging conditions, providing confidence to operators that their equipment will function effectively over time.

Hygiene and Cleanability

Another significant benefit of stainless steel impellers is their hygienic properties. In industries such as food and pharmaceuticals, cleanliness is paramount. Stainless steel’s non-porous surface prevents the accumulation of bacteria and other contaminants, making it easy to clean and sanitize. This characteristic is essential for maintaining safety standards and ensuring product quality.

Moreover, stainless steel can be easily fabricated into complex designs that optimize fluid flow while maintaining hygiene. State-of-the-art cleaning processes, including CIP (Clean-In-Place) systems, can be utilized, allowing for efficient cleaning without disassembling the equipment. This reduces downtime and increases productivity, making stainless steel an invaluable material in modern manufacturing.

impeller stainless steel

Material Versatility and Efficiency

Stainless steel impellers are not limited to a single design or application. Engineers can manipulate various grades of stainless steel to tailor the impellers' mechanical properties and performance characteristics. For example, an impeller utilized in a high-temperature environment might be constructed from stainless steel with higher nickel content, enhancing its heat resistance.

Furthermore, the ability to fabricate stainless steel impellers in various shapes and sizes allows for high levels of customization. This adaptability means that companies in different sectors—such as aerospace, petrochemicals, and pharmaceuticals—can benefit from highly efficient impeller designs that meet their distinct operational needs. Enhanced designs lead to improved fluid dynamics, resulting in increased energy efficiency and reduced operational costs.

Economic Considerations

While high-quality stainless steel impellers may have a higher upfront cost than those made from other materials, the long-term benefits generally outweigh the initial investment. The durability, corrosion resistance, and reduced maintenance requirements contribute to lower lifecycle costs, making stainless steel a cost-effective choice in the long run. Additionally, the extended lifespan of stainless steel impellers means fewer replacements, further reducing costs associated with production downtime and material waste.

Conclusion

In conclusion, the significance of stainless steel impellers in modern engineering cannot be overstated. Their durability, resistance to corrosion, hygienic properties, versatility, and economic advantages make them essential components in a wide array of applications. As industries continue to evolve and the need for more efficient and sustainable processes grows, stainless steel impellers will undoubtedly remain a critical element in engineering solutions. By choosing stainless steel, manufacturers not only ensure high performance and reliability but also contribute to a more sustainable future, as these materials align with the principles of longevity and reduced waste.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025