Mobile:+86-311-808-126-83

Email:info@ydcastings.com

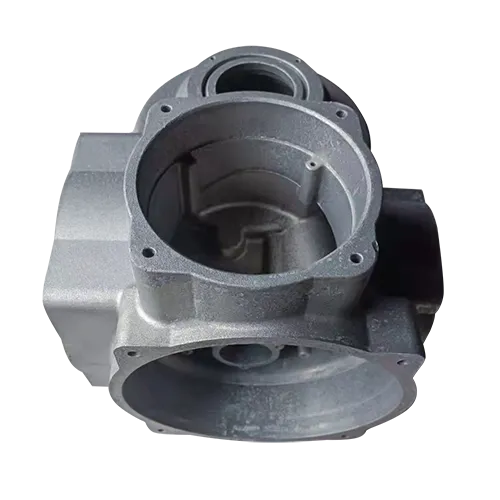

Stainless Steel Impeller for Enhanced Performance and Durability in Various Applications

The Significance of Stainless Steel Impellers in Modern Industry

In the realm of industrial machinery and fluid dynamics, impellers play a crucial role in the efficient movement of liquids and gases. Among various materials, stainless steel has emerged as a preferred choice for manufacturing impellers, owing to its unique properties and advantages.

The Significance of Stainless Steel Impellers in Modern Industry

The strength and durability of stainless steel also contribute significantly to the performance of impellers. These components are subject to high rotational speeds and pressures, which necessitate materials that can withstand significant stress without deforming. Stainless steel, particularly grades like 316 and 304, offers impressive tensile strength, ensuring that the impellers can operate efficiently under demanding conditions. This durability translates to longer operational life and reduced maintenance costs, which is crucial for companies looking to optimize their resources.

impeller stainless steel

Another essential characteristic of stainless steel impellers is their ease of fabrication. Stainless steel can be easily molded, welded, and machined, allowing for precise manufacturing of impellers tailored to specific designs and operational requirements. This precision in engineering contributes to improved efficiency, as well-designed impellers can optimize flow patterns and energy consumption.

Moreover, the hygienic properties of stainless steel make it an ideal choice for industries that require strict cleanliness standards, such as food and beverage processing and pharmaceuticals. The non-porous nature of stainless steel prevents bacteria and other contaminants from adhering to its surface, making it easier to clean and maintain hygiene levels. This is particularly important in environments where product safety and quality are paramount.

Apart from these technical benefits, using stainless steel impellers can also enhance the overall aesthetic appeal of machinery. The shiny, polished surface of stainless steel not only looks professional but also signifies quality and reliability to clients and customers.

In conclusion, stainless steel impellers serve as a crucial component in many industrial applications due to their corrosion resistance, strength, fabrication versatility, and hygienic properties. As industries continue to evolve and demand higher standards of performance and safety, the role of stainless steel impellers is set to grow, solidifying their importance in modern engineering and manufacturing. Investing in stainless steel impellers is not merely about selecting a material but making a strategic choice for sustainability, efficiency, and reliability in an increasingly demanding industrial landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025