Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 16, 2025 14:31

Back to list

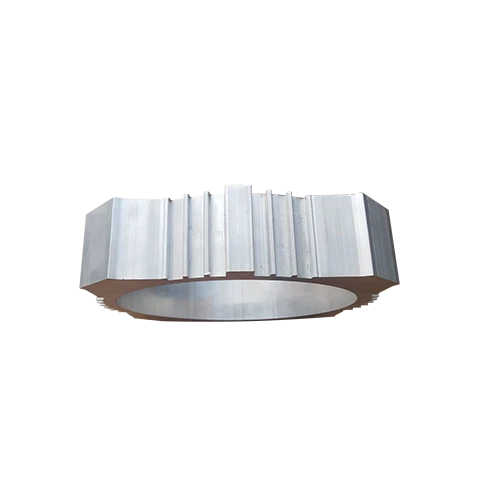

impeller of fan

The impeller of a fan is a pivotal component that significantly influences the performance, efficiency, and overall functionality of any fan system. Serving as the dynamic heart of the fan, the impeller's design, material, and construction play a crucial role in how effectively a fan can move air within a given environment. Understanding the intrinsic details of fan impellers can help consumers make informed decisions while enhancing the credibility and authority of businesses specializing in fan production and maintenance.

Trustworthiness also plays a pivotal role in how impellers are perceived in the marketplace. Manufacturers and distributors who provide transparent information about their impeller designs, manufacturing processes, and material sources foster greater trust with their clientele. By ensuring that potential buyers have access to detailed product specifications and performance reviews, these businesses strengthen their reputation. Furthermore, customers who share positive testimonials about the durability and efficiency of a fan’s impeller can significantly enhance brand credibility, leading to increased consumer confidence and loyalty. In terms of product innovation, emerging advancements in materials science are paving the way for even more sophisticated impeller designs. The incorporation of lightweight composite materials and the development of variable geometry blades that can adjust to changing operational demands are just a couple of the exciting innovations on the horizon. These developments promise to deliver unparalleled performance levels, offering quieter, more efficient, and eco-friendly fan solutions. In conclusion, the impeller of a fan is far more than just a spinning component; it is a fundamental determinant of the fan's quality, efficiency, and longevity. For those involved in the production, distribution, or maintenance of fan systems, a deep understanding of impeller characteristics is essential. By focusing on expert engineering, adherence to authoritative standards, and fostering consumer trust through transparency, companies can leverage the impeller as a key differentiator in the competitive landscape of fan technology. As the demand for more sustainable and efficient environmental management solutions rises, the impeller will undoubtedly continue to be a focal point of innovation and expertise within the industry.

Trustworthiness also plays a pivotal role in how impellers are perceived in the marketplace. Manufacturers and distributors who provide transparent information about their impeller designs, manufacturing processes, and material sources foster greater trust with their clientele. By ensuring that potential buyers have access to detailed product specifications and performance reviews, these businesses strengthen their reputation. Furthermore, customers who share positive testimonials about the durability and efficiency of a fan’s impeller can significantly enhance brand credibility, leading to increased consumer confidence and loyalty. In terms of product innovation, emerging advancements in materials science are paving the way for even more sophisticated impeller designs. The incorporation of lightweight composite materials and the development of variable geometry blades that can adjust to changing operational demands are just a couple of the exciting innovations on the horizon. These developments promise to deliver unparalleled performance levels, offering quieter, more efficient, and eco-friendly fan solutions. In conclusion, the impeller of a fan is far more than just a spinning component; it is a fundamental determinant of the fan's quality, efficiency, and longevity. For those involved in the production, distribution, or maintenance of fan systems, a deep understanding of impeller characteristics is essential. By focusing on expert engineering, adherence to authoritative standards, and fostering consumer trust through transparency, companies can leverage the impeller as a key differentiator in the competitive landscape of fan technology. As the demand for more sustainable and efficient environmental management solutions rises, the impeller will undoubtedly continue to be a focal point of innovation and expertise within the industry.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS