Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 16, 2025 14:13

Back to list

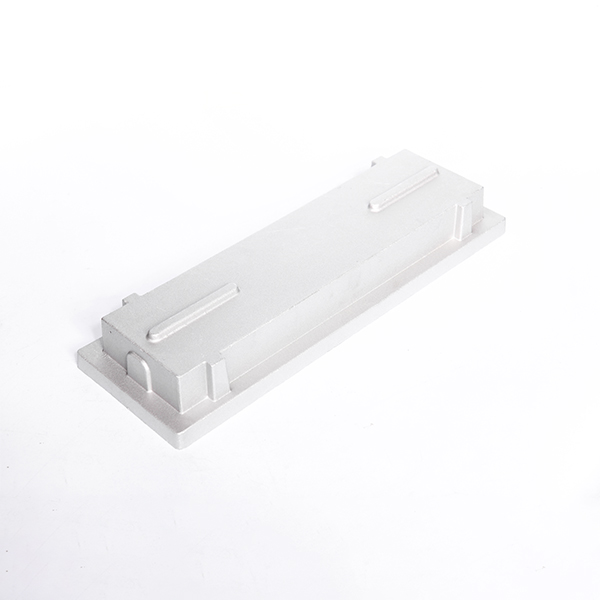

impeller in turbine

In the world of advanced engineering and energy production, the impeller in a turbine stands as a critical component that greatly influences performance and efficiency. These intricately designed rotors are central to the operation of various types of turbines, including those used in power plants, jet engines, and industrial applications. This article explores the multifaceted role of impellers, offering insights into their designs, applications, and the technical expertise required to optimize their functionality.

The concept of maintaining and optimizing turbine impellers ties into the broader conversation about reliability and efficiency. Regular maintenance is key to ensuring that impellers perform optimally over their lifespan. This includes thorough inspections for wear and tear, material degradation, and alignment issues, all of which can affect a turbine's performance. Predictive maintenance strategies, incorporating the latest in sensor technology and data analytics, are becoming increasingly important, providing operators with the authority to predict potential failures before they occur. Moreover, the trustworthiness of turbine operations greatly depends on the expertise of professionals involved in their maintenance and design. Engineers and technicians with specialized training are tasked with ensuring that impellers and the turbines they support operate smoothly and efficiently. Training programs and continuous education are foundational to maintaining a level of expertise that instills confidence in both operators and clients. In various industries, whether it be energy production or aviation, the authoritative knowledge around turbine impellers cannot be overstated. Advances in technology continuously push the boundaries of what these components can achieve, making continuous research and development an integral part of the sector. Collaborative efforts among engineering firms, research institutions, and industry stakeholders are vital to further innovations, increasing the efficiency of energy conversion, and reducing the environmental footprint of turbine operations. In essence, the impeller in a turbine is not just a mechanical component; it is a symbol of human ingenuity and engineering excellence. As technology progresses, the role of the impeller will undoubtedly expand, continuing to challenge engineers to refine their designs, enhance performance, and improve sustainability. By understanding the critical functions and the depth of expertise required to manage these components, industries can continue to advance in a rapidly changing world, producing energy more efficiently and sustainably than ever before.

The concept of maintaining and optimizing turbine impellers ties into the broader conversation about reliability and efficiency. Regular maintenance is key to ensuring that impellers perform optimally over their lifespan. This includes thorough inspections for wear and tear, material degradation, and alignment issues, all of which can affect a turbine's performance. Predictive maintenance strategies, incorporating the latest in sensor technology and data analytics, are becoming increasingly important, providing operators with the authority to predict potential failures before they occur. Moreover, the trustworthiness of turbine operations greatly depends on the expertise of professionals involved in their maintenance and design. Engineers and technicians with specialized training are tasked with ensuring that impellers and the turbines they support operate smoothly and efficiently. Training programs and continuous education are foundational to maintaining a level of expertise that instills confidence in both operators and clients. In various industries, whether it be energy production or aviation, the authoritative knowledge around turbine impellers cannot be overstated. Advances in technology continuously push the boundaries of what these components can achieve, making continuous research and development an integral part of the sector. Collaborative efforts among engineering firms, research institutions, and industry stakeholders are vital to further innovations, increasing the efficiency of energy conversion, and reducing the environmental footprint of turbine operations. In essence, the impeller in a turbine is not just a mechanical component; it is a symbol of human ingenuity and engineering excellence. As technology progresses, the role of the impeller will undoubtedly expand, continuing to challenge engineers to refine their designs, enhance performance, and improve sustainability. By understanding the critical functions and the depth of expertise required to manage these components, industries can continue to advance in a rapidly changing world, producing energy more efficiently and sustainably than ever before.

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS