Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 20, 2025 05:13

Back to list

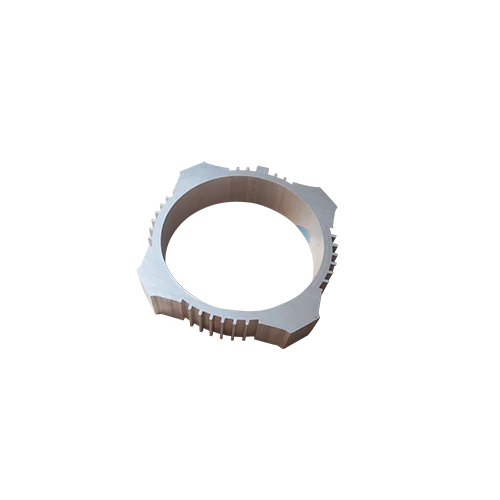

impeller casting

In the intricate world of manufacturing, impeller casting stands out as a fascinating sector that combines traditional techniques with modern innovations to create vital components used across various industries. Whether in automotive, aerospace, or energy production, impeller castings serve as indispensable parts of pumps and turbines, crucial for fluid movement and energy conversion. The crafting of these components, however, demands precision, expertise, and a deep understanding of material sciences and engineering principles.

Throughout the production chain, maintaining authority and trustworthiness is paramount. Manufacturers invest in certifications and adhere to international standards such as ISO 9001 to affirm their commitment to quality management. These credentials signal to clients that the manufacturer is reliable and that the products can be trusted to perform as expected. Furthermore, offering transparency through customer audits and third-party evaluations strengthens this bond of trust, making the manufacturer a preferred partner in the supply chain. Environmentally, the impeller casting industry is also making strides towards sustainability. Companies are increasingly adopting eco-friendly practices such as recycling metal waste and using energy-efficient equipment, addressing environmental concerns while maintaining production efficacy. Expertise in environmental engineering has become integral, as it allows for innovative solutions that reduce the carbon footprint and improve the overall sustainability of the casting process. Innovation continues to push the boundaries of impeller casting, with advancements in additive manufacturing and 3D printing offering new possibilities. These technologies enable more complex designs, reduced lead times, and cost savings in prototype development. Experts in these fields are pioneering new methods to integrate these technologies into traditional casting operations, resulting in products that are not only high-quality but also engineered for tomorrow's challenges. For businesses seeking reliable impeller casting solutions, partnering with a manufacturer that exemplifies experience, expertise, authority, and trustworthiness ensures peace of mind and product excellence. The impeller casting process is not just about producing a piece of metal but about crafting a vital component that powers industries and contributes to technological progress. In an era where precision and reliability are non-negotiable, choosing the right partner in impeller casting can make all the difference in achieving operational success and sustained innovation.

Throughout the production chain, maintaining authority and trustworthiness is paramount. Manufacturers invest in certifications and adhere to international standards such as ISO 9001 to affirm their commitment to quality management. These credentials signal to clients that the manufacturer is reliable and that the products can be trusted to perform as expected. Furthermore, offering transparency through customer audits and third-party evaluations strengthens this bond of trust, making the manufacturer a preferred partner in the supply chain. Environmentally, the impeller casting industry is also making strides towards sustainability. Companies are increasingly adopting eco-friendly practices such as recycling metal waste and using energy-efficient equipment, addressing environmental concerns while maintaining production efficacy. Expertise in environmental engineering has become integral, as it allows for innovative solutions that reduce the carbon footprint and improve the overall sustainability of the casting process. Innovation continues to push the boundaries of impeller casting, with advancements in additive manufacturing and 3D printing offering new possibilities. These technologies enable more complex designs, reduced lead times, and cost savings in prototype development. Experts in these fields are pioneering new methods to integrate these technologies into traditional casting operations, resulting in products that are not only high-quality but also engineered for tomorrow's challenges. For businesses seeking reliable impeller casting solutions, partnering with a manufacturer that exemplifies experience, expertise, authority, and trustworthiness ensures peace of mind and product excellence. The impeller casting process is not just about producing a piece of metal but about crafting a vital component that powers industries and contributes to technological progress. In an era where precision and reliability are non-negotiable, choosing the right partner in impeller casting can make all the difference in achieving operational success and sustained innovation.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS