Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Impeller housing selection criteria for centrifugal pumps in fluid dynamics applications

Casting impeller, also known as pump impeller, plays a crucial role in various industries such as water treatment, agriculture, and manufacturing. It is typically made from metal alloys such as stainless steel, bronze, or aluminum. The casting impeller is designed to efficiently move fluids or gases by rotating and creating a flow within a pump or compressor.

.

One of the key advantages of casting impeller is its ability to produce complex shapes and intricate designs with high precision. This makes casting impeller ideal for applications where efficiency and performance are critical. The smooth surface finish of cast impellers also allows for better fluid flow and reduces energy consumption.

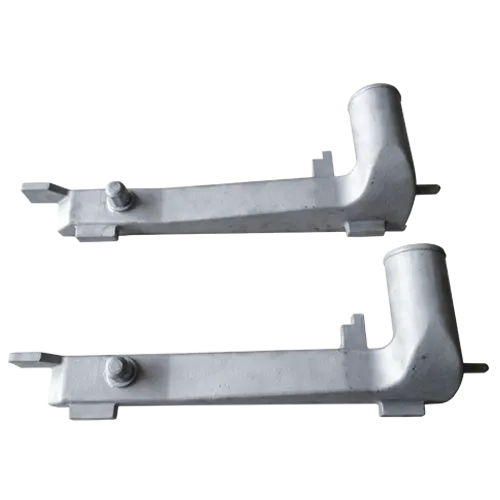

casing impeller

In addition to its precision and efficiency, casting impeller is also highly durable and resistant to wear and corrosion. This makes it suitable for use in harsh environments where exposure to abrasive materials or chemicals is common. The longevity of casting impeller ensures that equipment downtime is minimized, leading to increased productivity and cost savings for businesses.

Furthermore, casting impeller can be customized to meet specific requirements of different industries and applications. Whether it is a specific alloy material, size, or shape, casting impeller can be tailored to suit the needs of the customer. This customization ensures that the impeller performs optimally under various operating conditions.

Overall, casting impeller is a vital component in the operation of pumps and compressors across a wide range of industries. Its precision, efficiency, durability, and customizability make it the preferred choice for many businesses looking to improve their operations. With the ability to move fluids and gases efficiently and reliably, casting impeller is a key player in keeping industries running smoothly and efficiently.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025